Non-shuttle peg base line supplying device

A bobbin thread and bobbin technology, which is applied in textiles and papermaking, sewing equipment, sewing machine ring mechanism, etc., can solve the problems of not adapting to the thread feeding rhythm of the working part of the sewing machine, and achieve small changes in thread tension and smooth thread feeding , to avoid the effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

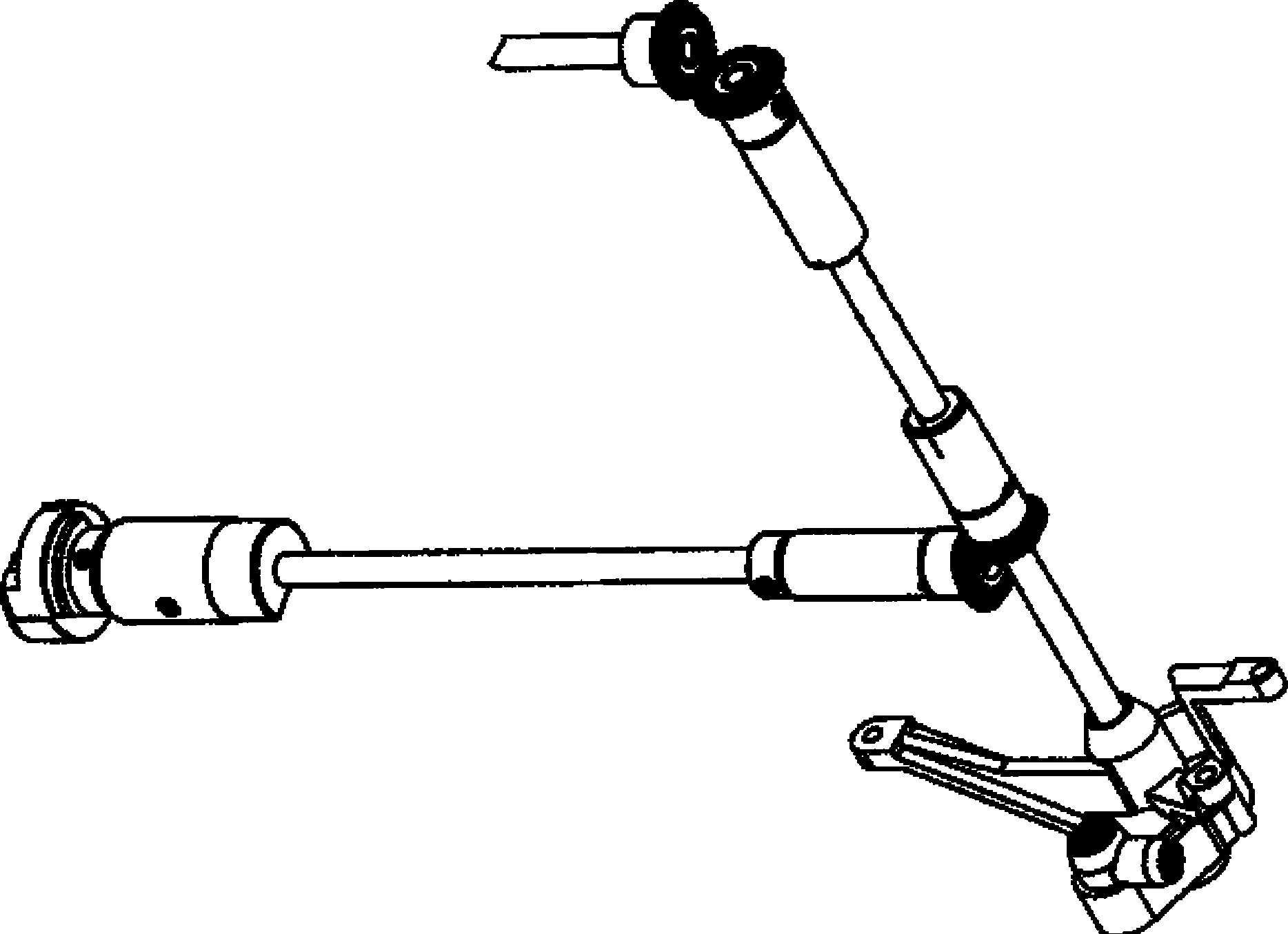

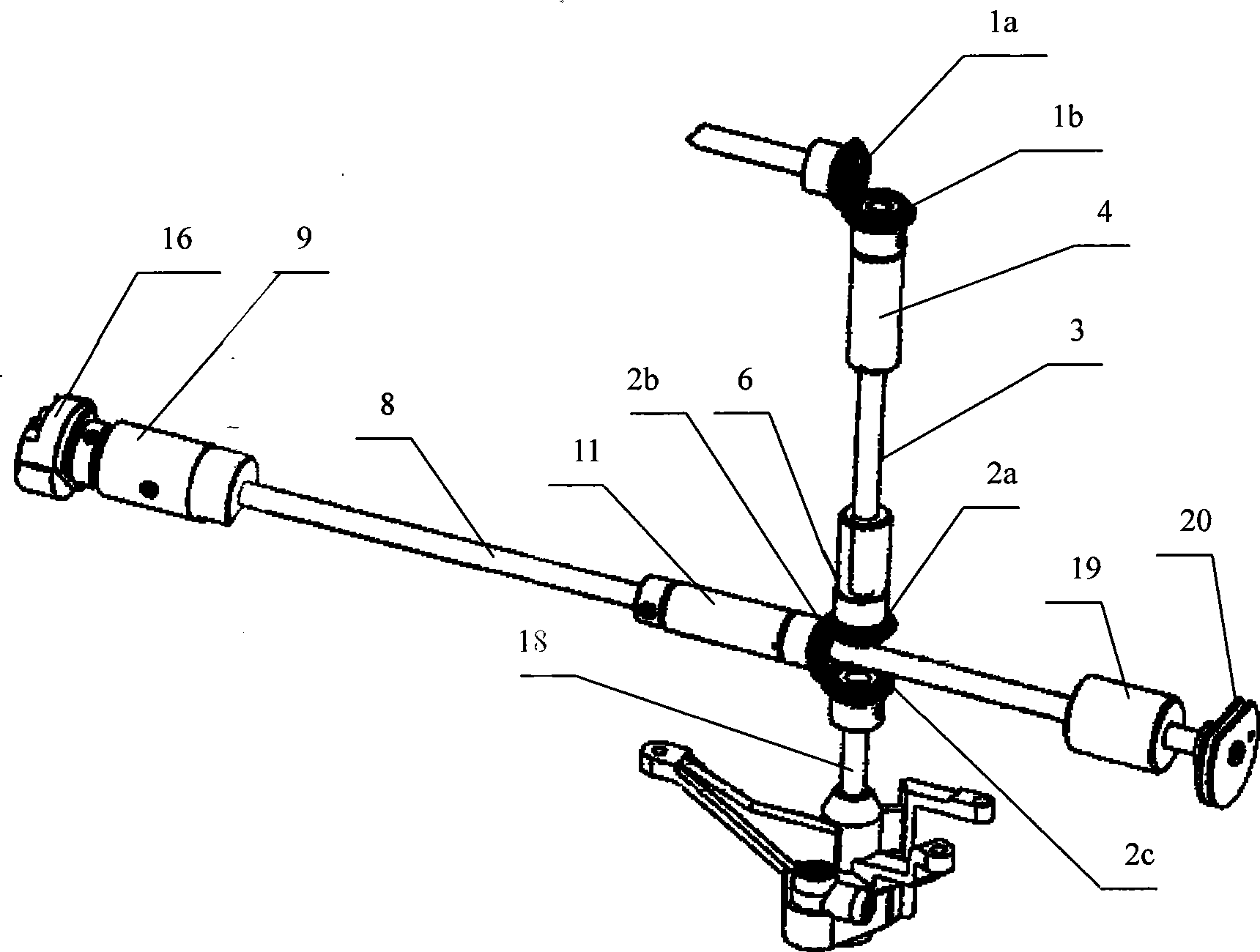

[0014] Refer to attached figure 2 , 3 : bobbinless bobbin thread providing device of the present invention comprises the rotary hook assembly installed on one end of the rotary hook shaft 8, the vertical shaft 3 vertically intersecting with the rotary hook shaft 8, and the rotary hook shaft 8 is provided with a hole for the thread body to pass through Shaft through hole, the hook shaft 8 extends beyond the intersection of the hook shaft 8 and the vertical shaft 3, the other end of the hook shaft 8 is equipped with a tensioning cam 20, the cam 20 is located on the thread path and is connected with the hook The shaft 8 is the center of rotation; the lower end of the vertical shaft 3 is connected with the hook shaft 8 through a bevel gear pair, and the upper end of the oil pump shaft 18 is connected with the hook shaft 8 through a bevel gear pair.

[0015] Described rotary hook cover 8, bevel gear, cam are all socketed on the rotary hook shaft 8, and are fixed with screw and ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com