Separator paper for alkaline-battery

A technology of alkaline batteries and separator paper, applied in the field of separator paper, can solve the problems of being unsuitable for high-power discharge, hindered ion diffusion, etc., and achieve the effects of enhancing liquid permeability, increasing absorption speed, and being beneficial to productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

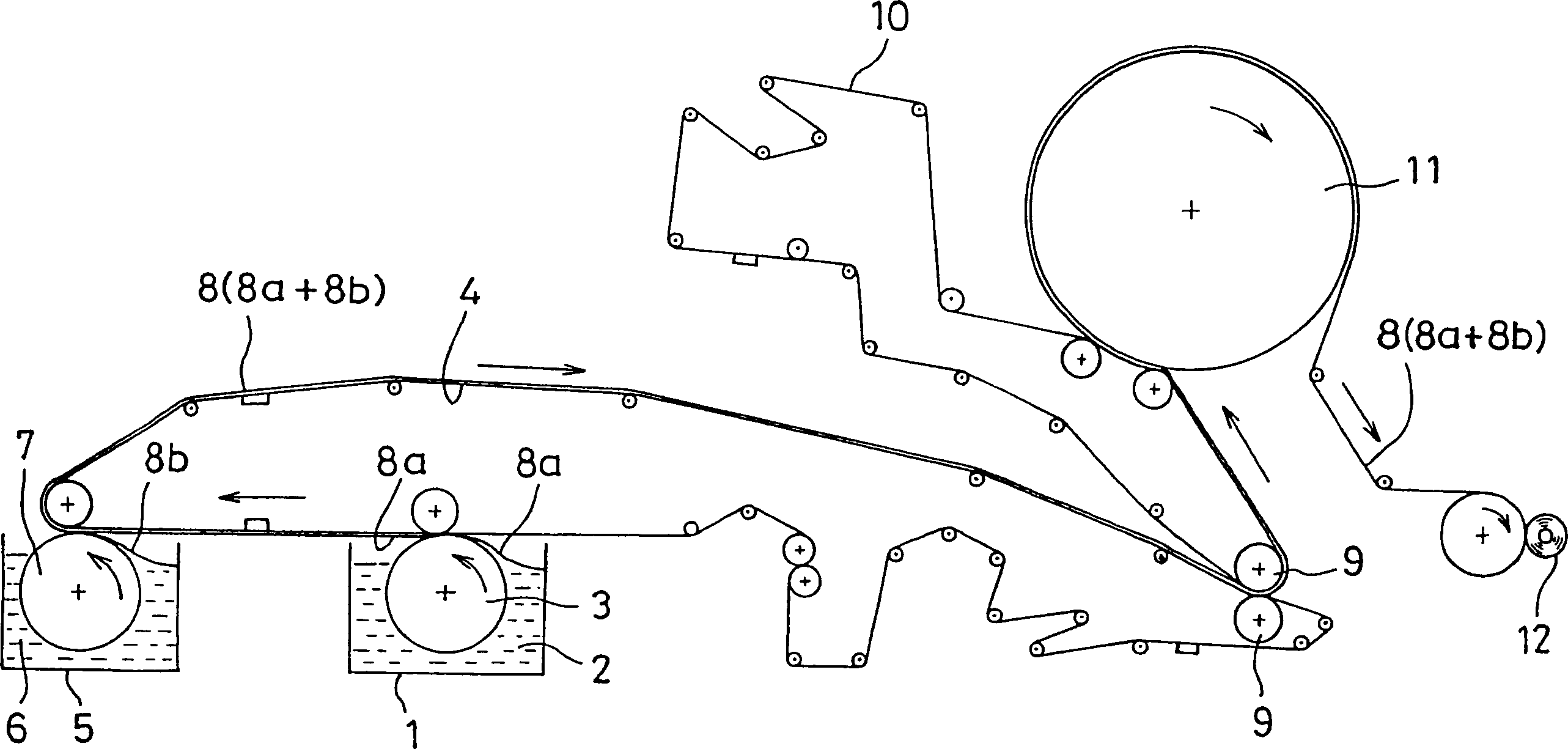

[0112] Embodiment 1: by figure 1 Double structure tight ply + liquid impregnated ply produced on cylinder paper machine shown.

[0113] For the compact layer, 63% by weight of mercerized hardwood pulp was beaten to up to 290ml CSF by a double disc refiner, mixed with 25% by weight of vinylon (fineness 0.5 denier x fiber length 2mm), and mixed with 12% by weight of Polyvinyl alcohol fibers (fineness 1 denier x fiber length 3mm) were mixed to provide furnish. In addition, for the liquid impermeable layer, 63% by weight of polynosic rayon (fineness 0.5 denier × fiber length 2mm), 25% by weight of vinylon (fineness 0.5 denier × fiber length 2mm) and 12% by weight By weight polyvinyl alcohol fibers (1 denier x 3 mm fiber length) were mixed together to provide the furnish. It should be noted that unbeaten polynosic rayon was used and had a CSF value of 740 ml. These raw materials are sent to two cylinder tanks respectively, and then laminated. During the papermaking process, th...

Embodiment approach 2

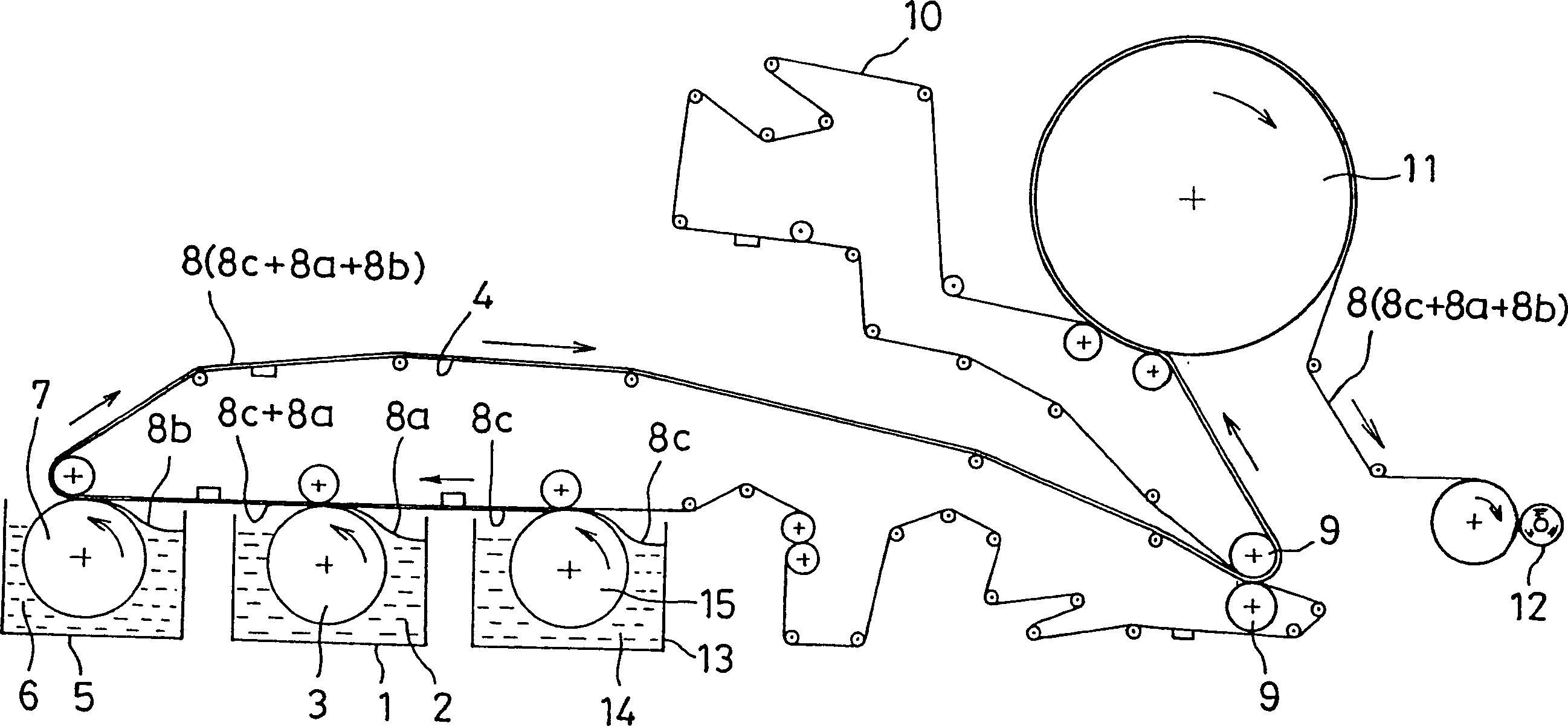

[0117] Embodiment 2 A triple structure of liquid impregnated layer+tight layer+liquid impregnated layer produced by the cylinder multilayer paper machine shown in the figure.

[0118] For the compact layer, 50% by weight of cotton linter pulp was beaten to up to 200ml CSF by double disc refiner, and mixed with 40% by weight of vinylon (0.5 denier x fiber length 2mm) and 10% by weight of polyvinyl alcohol fibers (fineness 1 denier x fiber length 3 mm) were mixed to provide a furnish. In addition, for the liquid impermeable layer, 60% by weight of common rayon (fineness 0.7 denier × fiber length 3mm), 28% by weight of vinylon (fineness 0.5 denier × fiber length 2mm) and 12% by weight poly Vinyl alcohol fibers (1 denier x 3 mm fiber length) were mixed together to provide the furnish. It should be noted that normal, unbeaten rayon was used and had a CSF value of 760 ml. These raw materials are sent to the three cylinders of the paper machine respectively, so that the figure 2 ...

Embodiment approach 3

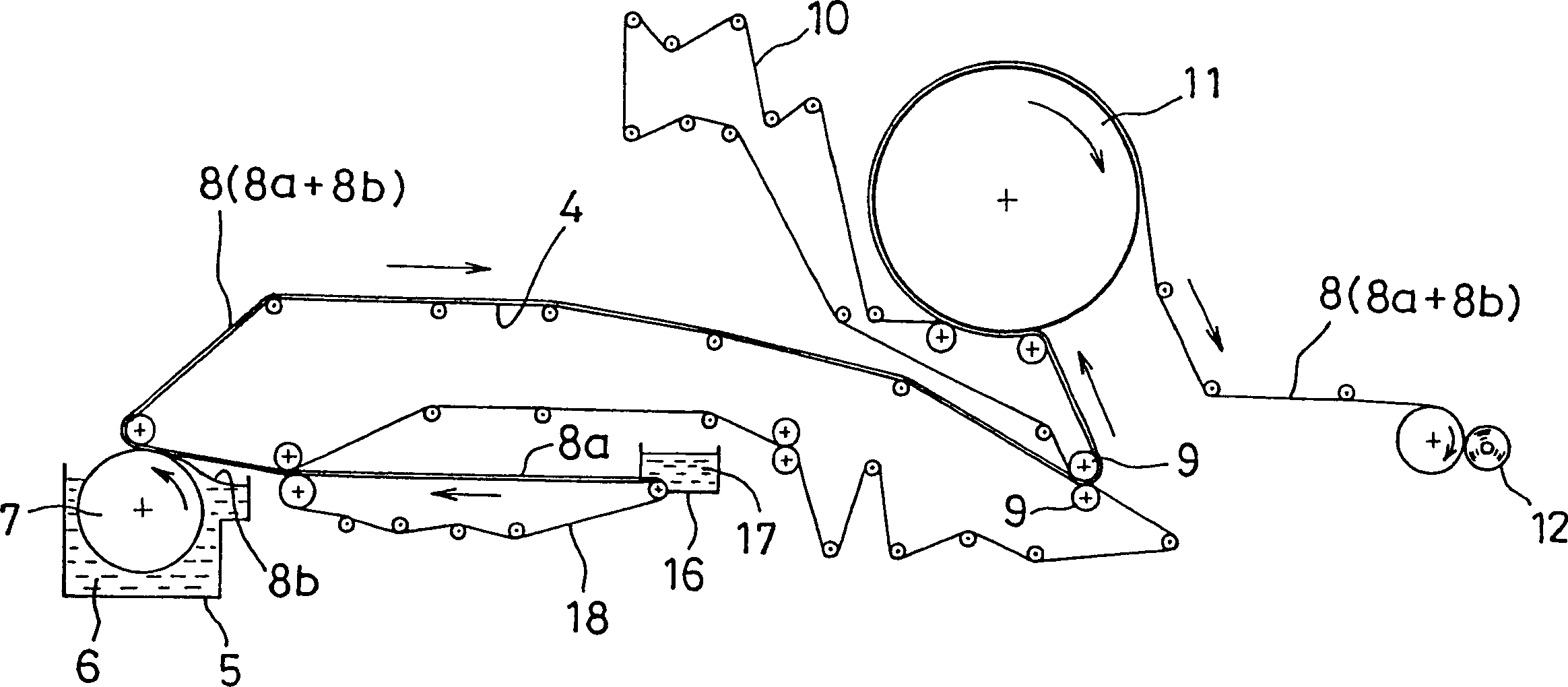

[0121] Embodiment 3 consists of image 3 The two-layer compact layer + liquid impregnated layer produced by the cylinder wire-fourdrinier composite paper machine shown.

[0122] For the compact layer, solvent spun rayon (fineness 1.5 denier x fiber length 4mm): 70% by weight of Tencel (Tencel is a trade mark of Coutlouse Co., UK) was beaten to at most 10 ml CSF by a double disc mill and mixed with 25% by weight of vinylon (0.5 denier x fiber length 2 mm) was mixed with 5% by weight polyvinyl alcohol fibers (fineness 1 x fiber length 3 mm) to provide a furnish. In addition, for the liquid impermeable layer, 60% by weight of polynosic rayon (fineness 0.5 denier × fiber length 2mm), 25% by weight of vinylon (fineness 0.5 denier × fiber length 2mm) and 15% by weight By weight polyvinyl alcohol fibers (1 denier x 3 mm fiber length) were mixed together to provide the furnish. It should be noted that unbeaten polynosic rayon was used and had a CSF value of 740 ml. These raw materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com