Engine variable valve lift mechanism capable of implementing vat destruction function and its control method

A valve lift and engine technology, applied in engine control, combustion engine, machine/engine, etc., can solve problems such as insufficient cylinder air intake, and achieve the effects of improving air flow, sufficient fuel combustion, and increasing impulse coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

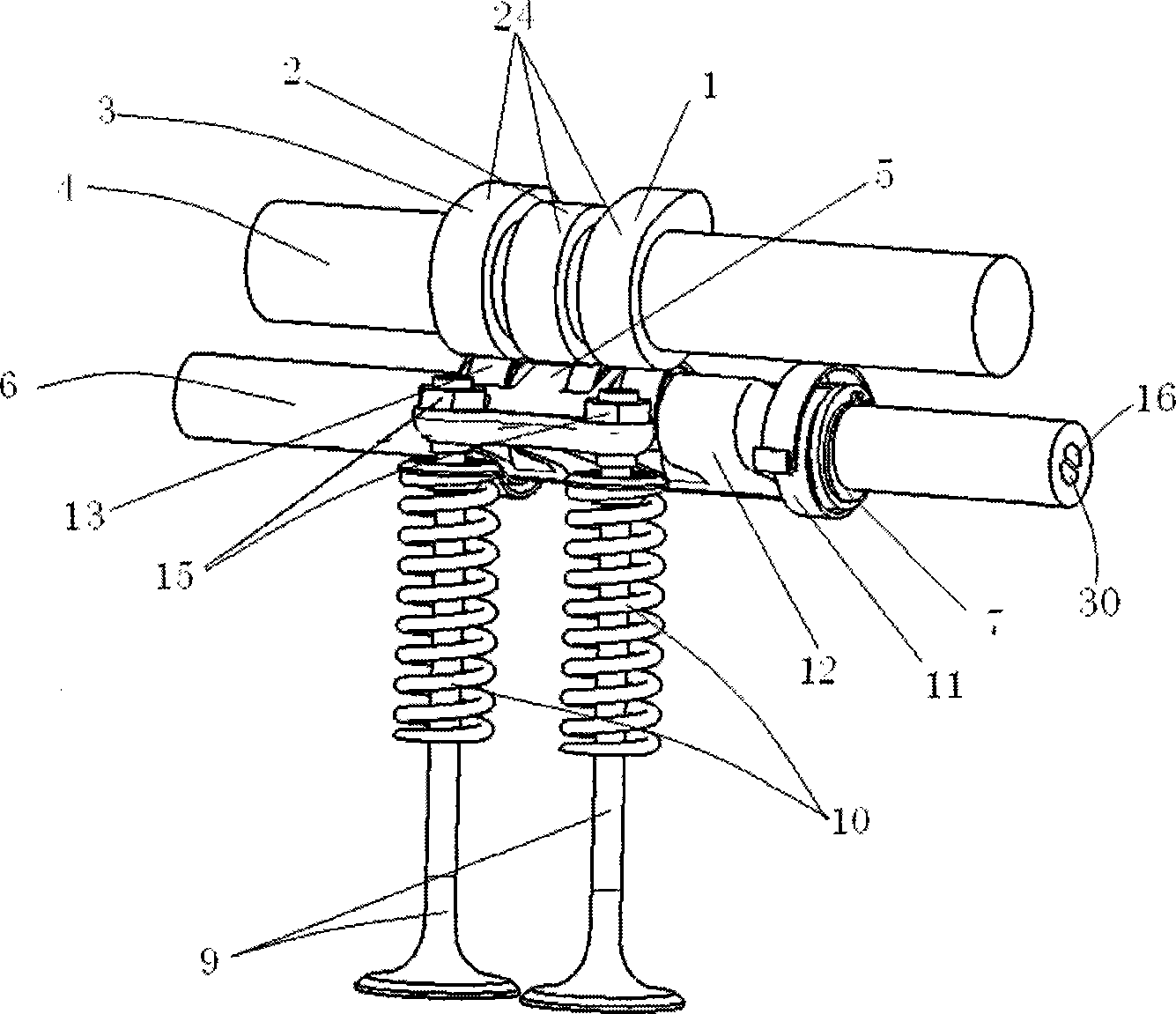

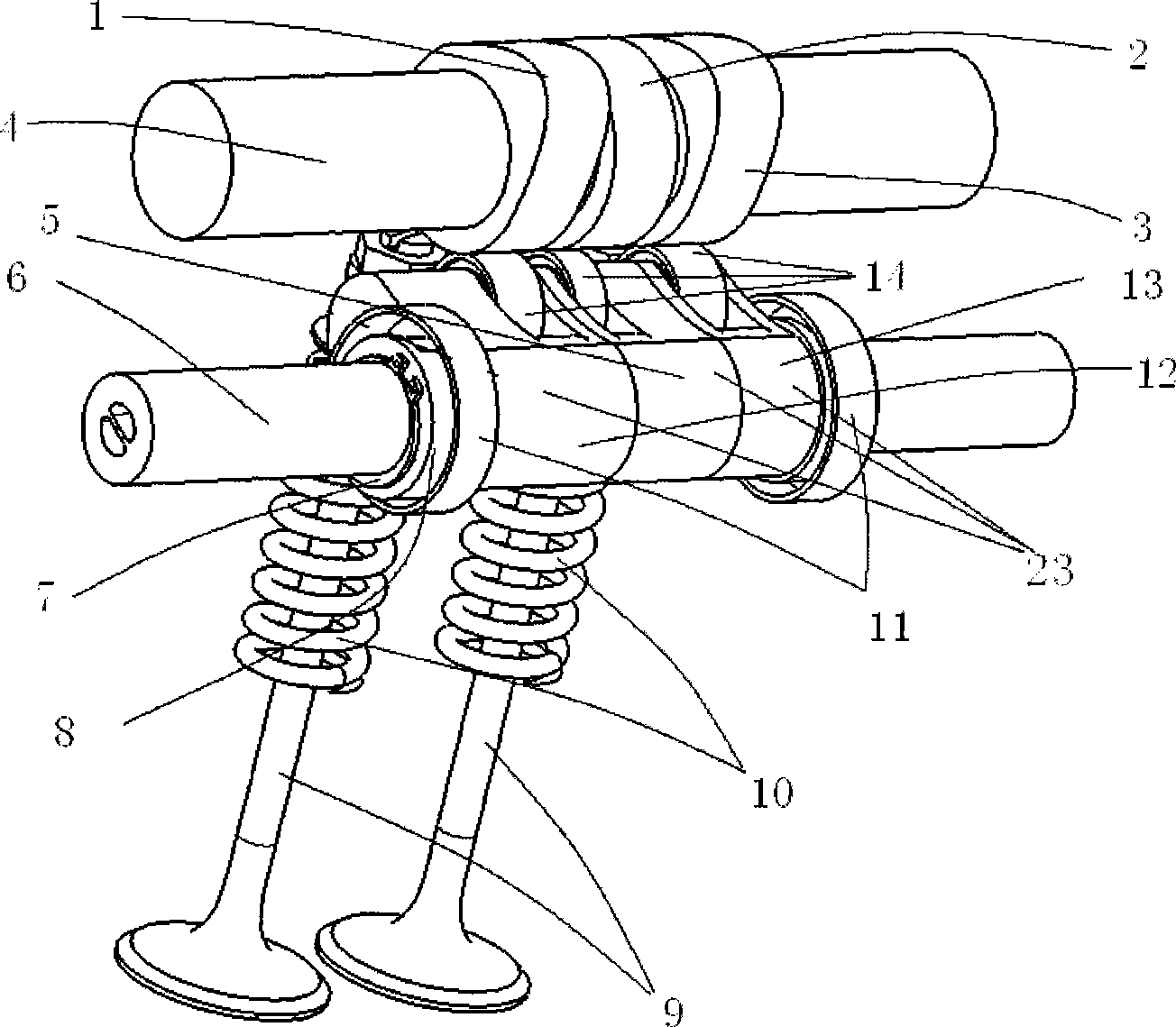

[0028] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

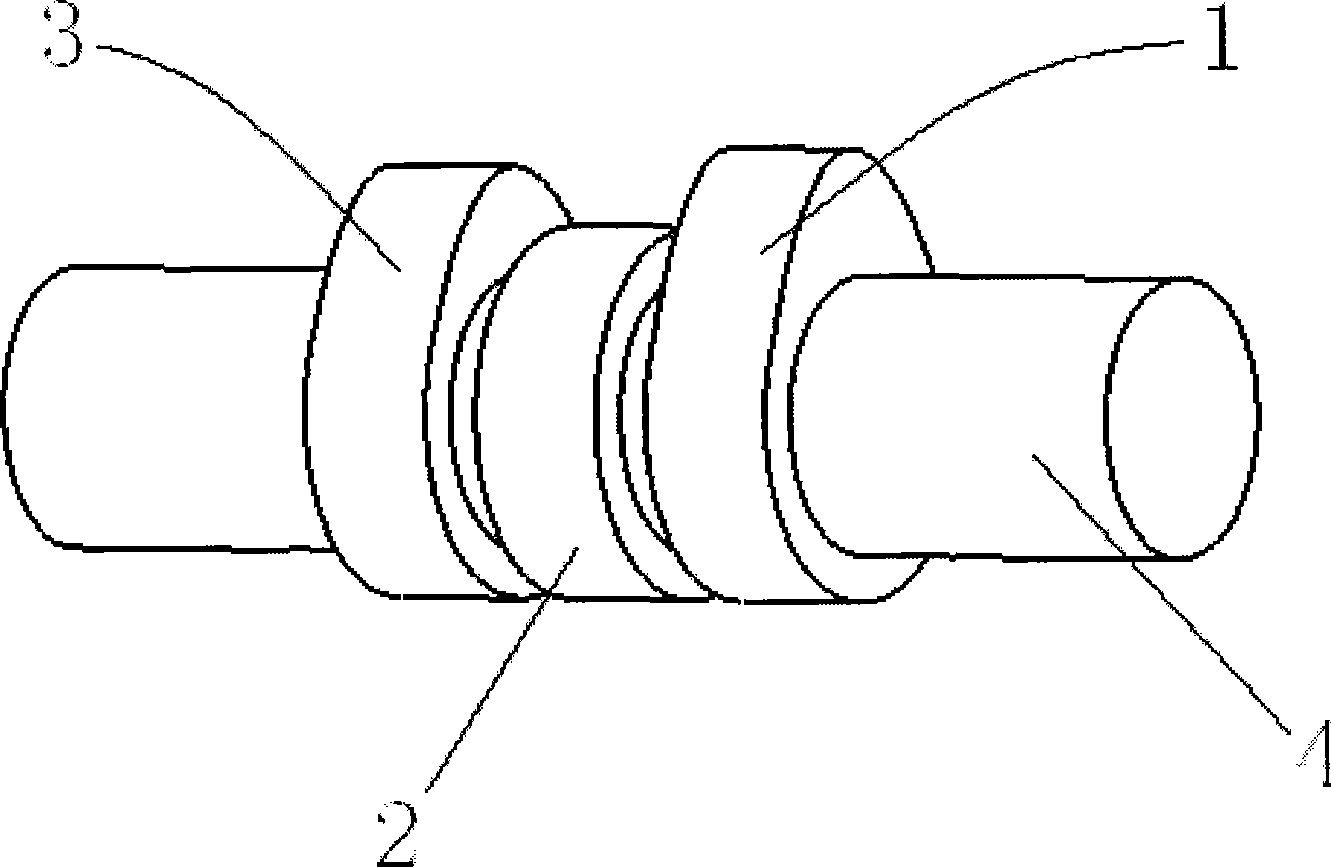

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the present invention is an engine variable valve lift mechanism capable of realizing the cylinder killing function, including a camshaft 4, a rocker shaft 6, a valve 9, a valve spring 10, a roller 14, a rocker arm 23, and a return spring 11. The camshaft 1 corresponding to each combustion chamber includes more than two cams 24 with different cam top heights; the number of rocker arms 23 corresponds to the number of cams 24; The arm shaft 8 is provided with a T-shaped pin 23, a short T-shaped loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com