Reciprocating apparatus capable of generating multiplied oil cylinder stroke

A technology of reciprocating motion and oil cylinder, applied in the field of linear reciprocating motion drive mechanism, to achieve the effect of low cost, simple structure and shortened overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is described in further detail below in conjunction with the embodiment given with accompanying drawing.

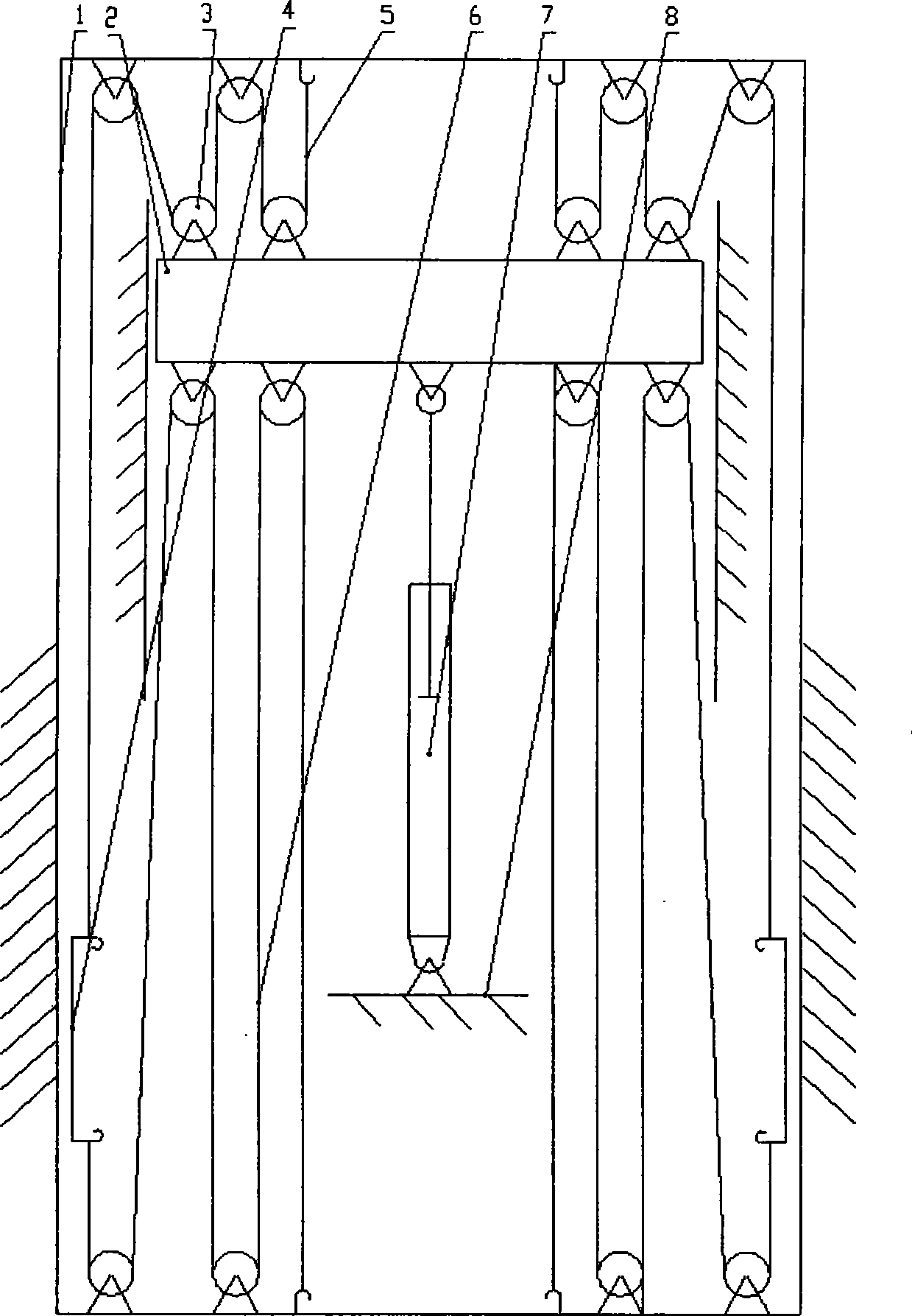

[0010] refer to figure 1 , a reciprocating motion device that can produce multiple times the stroke of the oil cylinder, a pulley frame 2 driven and connected by a frame 1, an oil cylinder 7 arranged on the frame 1, and two sets of pulley mechanisms symmetrically arranged between the frame 1 and the pulley frame 2 It is composed of a slide plate 4 that is driven and connected to the pulley mechanism to reciprocate up and down along the frame 1 slideway; each set of pulley mechanisms is formed in the following manner: two pulleys 3 are respectively arranged at the upper and lower ends of the frame 1, The upper and lower sides of the pulley frame 2 are respectively provided with the same number of pulleys 3, and one end of the rising steel rope 5 is fixedly connected to the upper end of the frame 1, and the other end is from a pulley on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com