Replacement type ventilation method and system for large spacing factory building of open type reaction groove

A ventilation method and reaction tank technology, applied in the direction of ventilation system, space heating and ventilation, applications, etc., can solve the problems of not being able to realize the local ventilation system at the side of the tank, occupying the space position, etc., and achieve the effect of reducing energy consumption and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

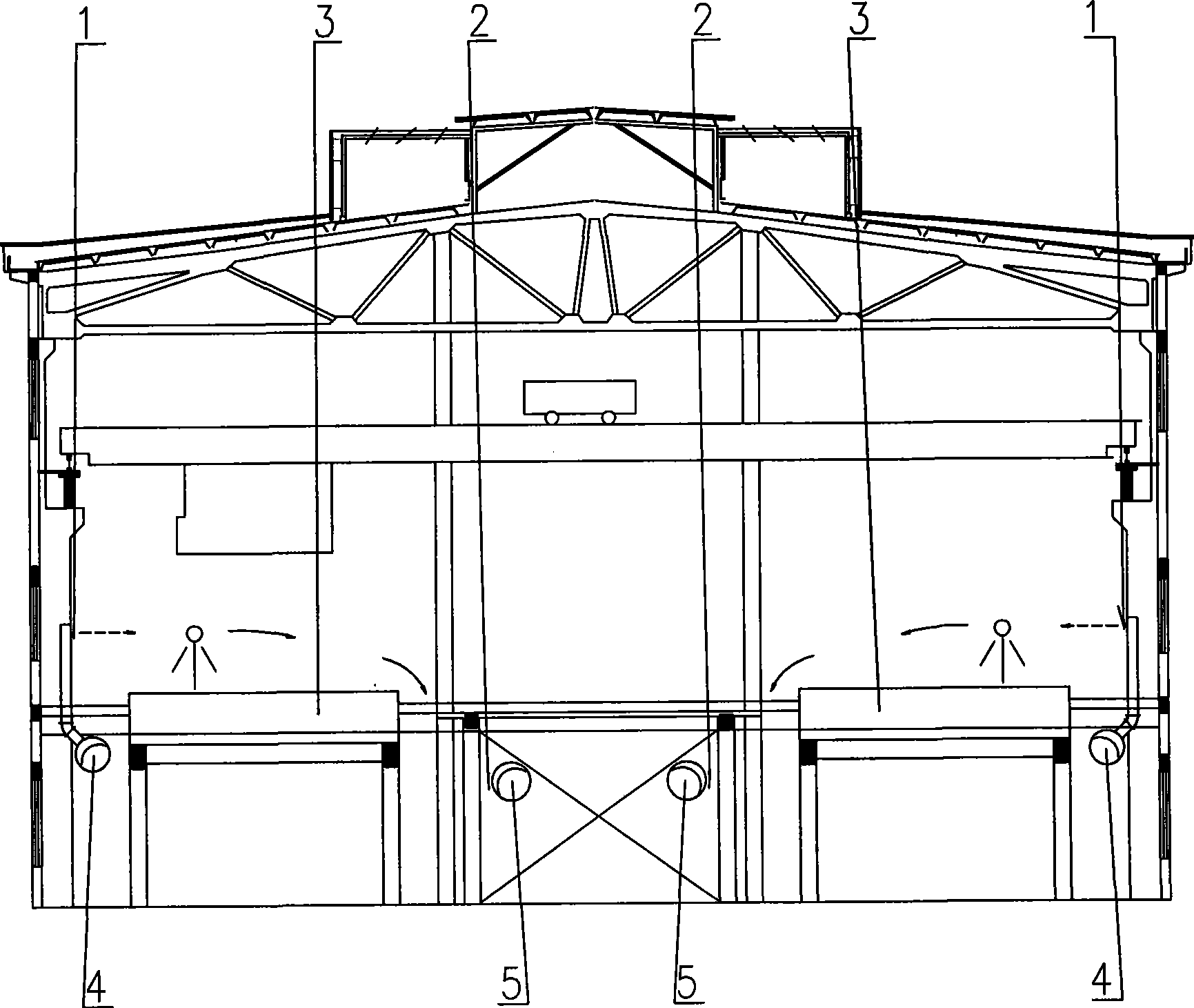

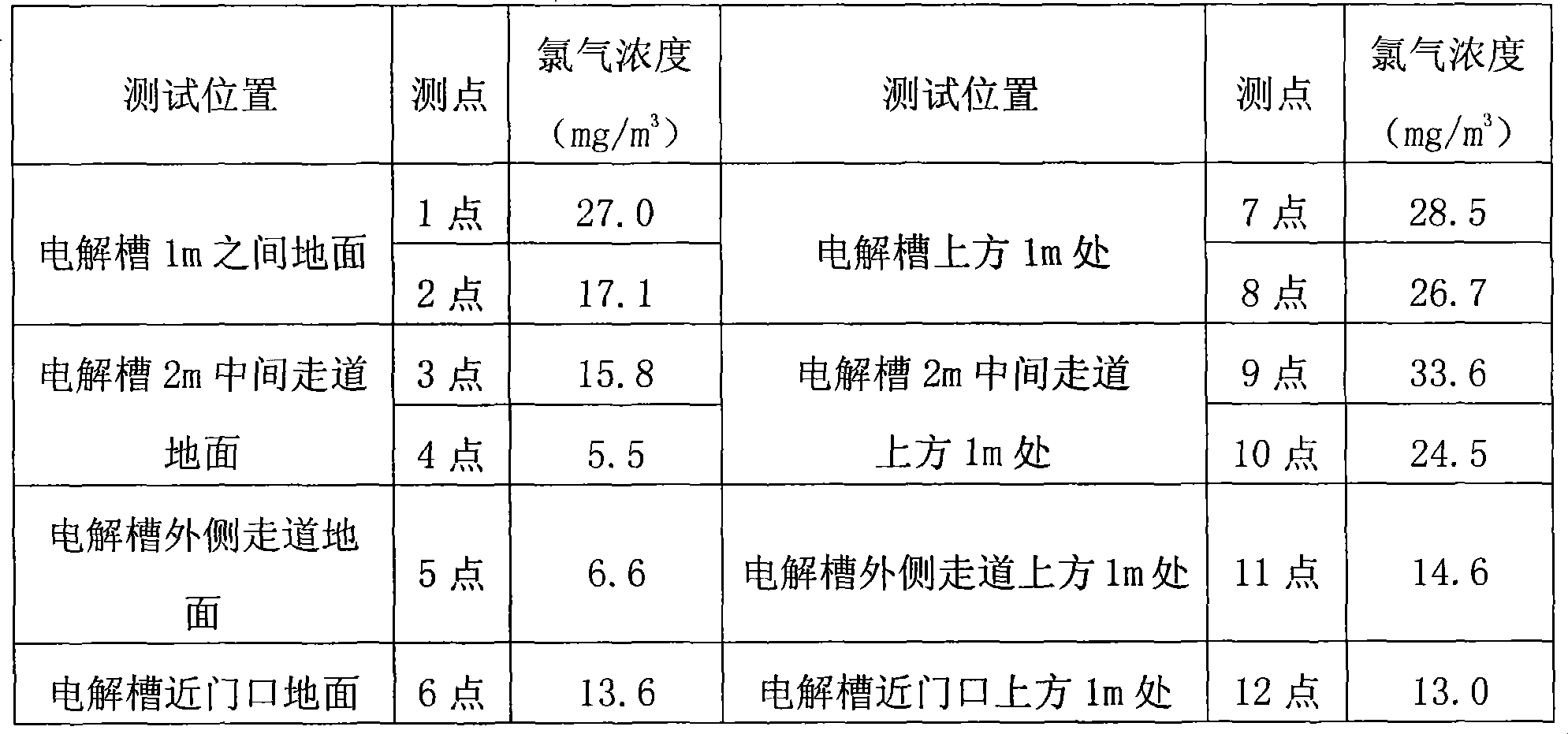

[0020] There are 44 open electrolytic cells in a tall cobalt electrodeposition workshop, which are placed in an area with a length of 48m, a width of 27m, and a height of 14m, which is half of the volume of the workshop. When the electrolyte cobalt chloride solution is heated to 55-65°C, it decomposes to generate chlorine gas. Although most of the hot gas from the electrolyte is discharged through the tank side process recovery pipe, part of the chlorine vapor is still emitted indoors as the hot gas rises. In general, windows are opened in the workshop for natural ventilation. When the wind and sand come and close the windows, the personnel in protective clothing and masks can only operate for a while, and the environment is very harsh.

[0021] (1) Properties of chlorine gas

[0022] Chlorine is a poisonous gas with a strong, choking odor. In a near-standard state, the vapor density of chlorine gas is 2.49kg / m 3 , 2 times higher than air. Therefore, when chlorine gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com