Building-integrated water container heat collection type solar energy utilization method

A technology of solar energy and solar heat collectors, applied in the field of solar energy utilization, can solve the problems of affecting the city landscape, large heat loss, and inability of solar water heaters, etc., and achieves the effect of significant environmental protection benefits and improved cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

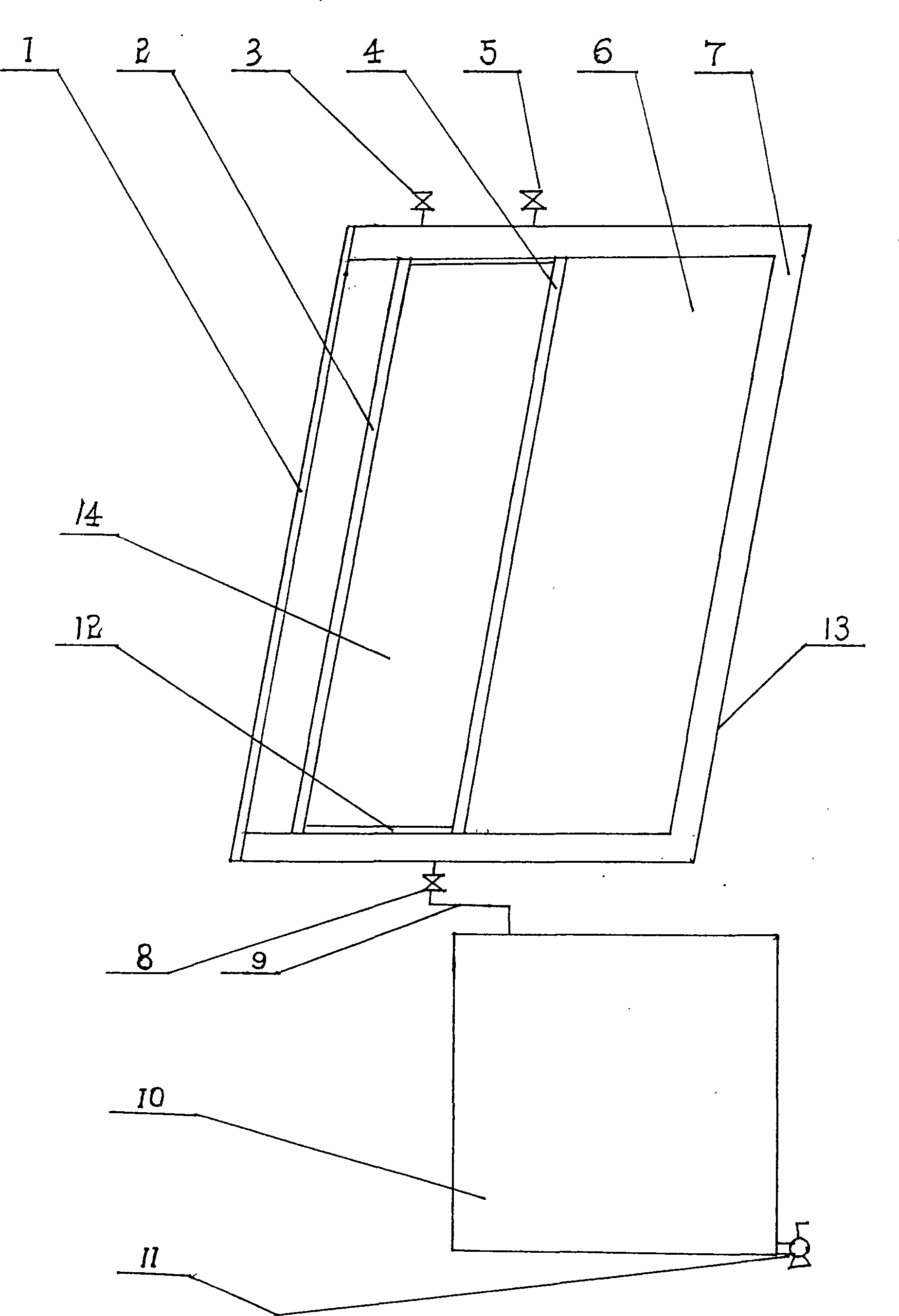

[0020]In the accompanying drawings, the heat collector cover (1) is made of materials such as glass or fiberglass with better light transmittance; It can be made of stainless steel or ordinary steel plate or glass, and its surface is sprayed with a selective paint with good heat absorption; the distance between the cover plate of the hot water tank (2) and the cover plate of the heat collector (1) is set to 1 cm- 10 centimeters, with 2 centimeters-5 centimeters being the best; the cold water control valve (3) of the hot water tank is an electromagnetic control valve, and when the cold water is filled with the hot water tank (14), it is automatically closed; the bottom plate of the hot water tank (4 ) and the box plate (12) of the water collecting tank (14) do not need to be made of expensive materials such as copper or copper aluminum alloy (known solar water heaters generally use copper as the heat collecting tube), and steel plates with relatively low prices can be used Meta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap