Novel thermoelectric circulation combined engine

An engine and turbojet engine technology, applied in the field of aero-engines, can solve the problems of insufficient utilization efficiency of engine thermal energy and unavailability of waste heat, and achieve the effects of improving thermal efficiency and fuel utilization rate, improving energy utilization efficiency, and simplifying turbine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

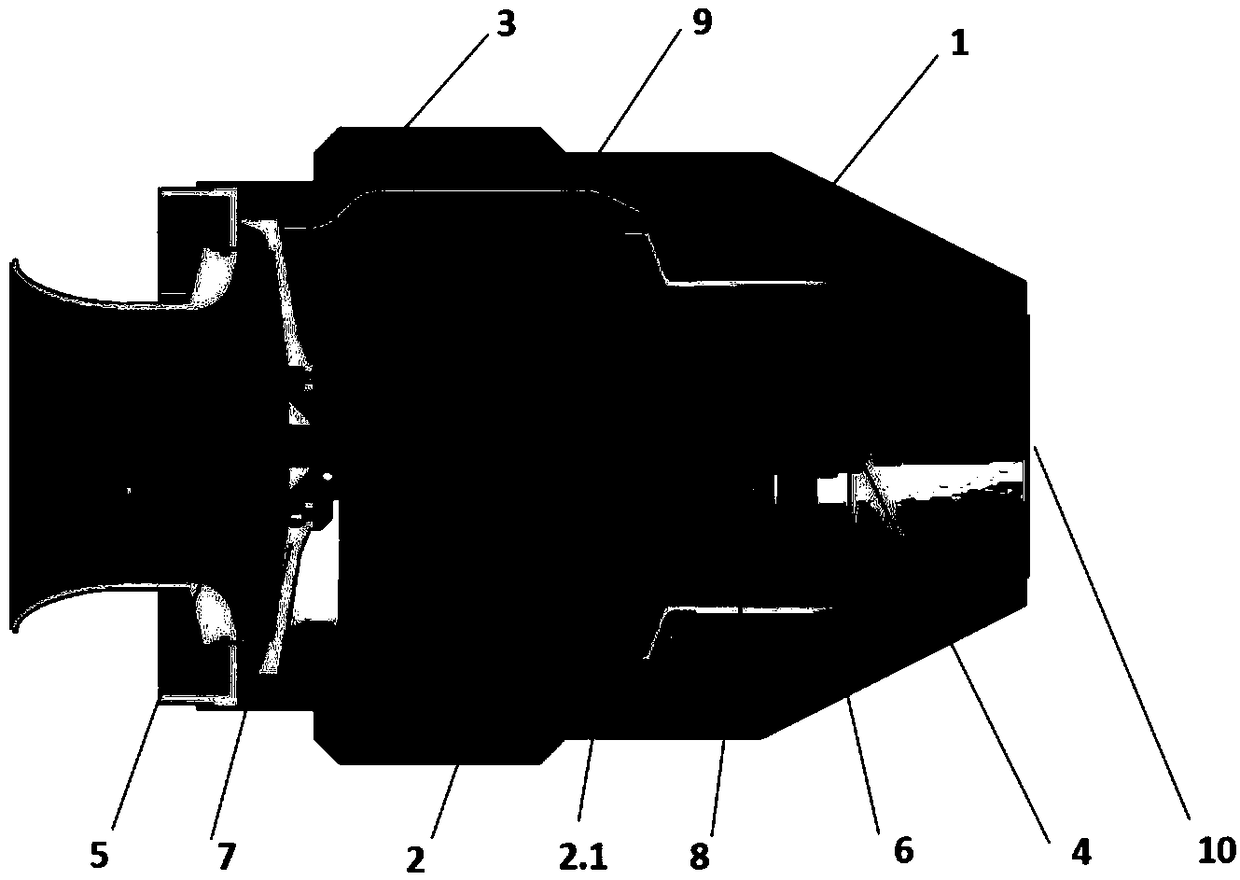

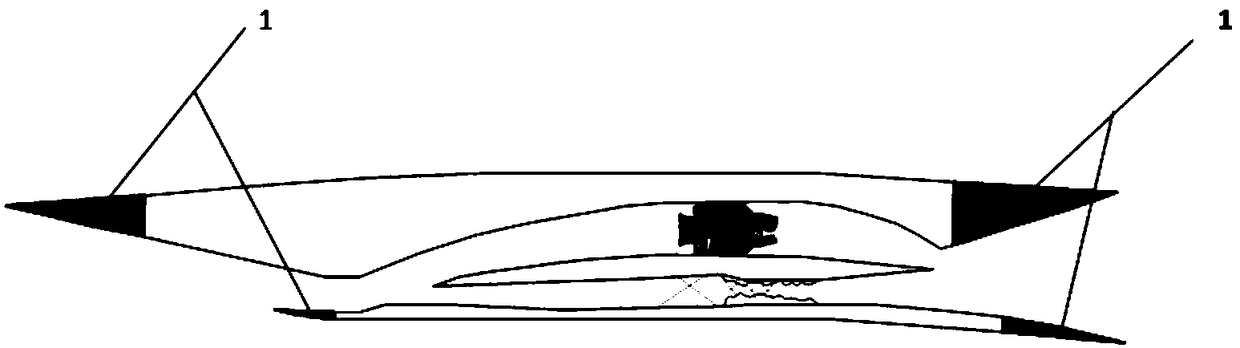

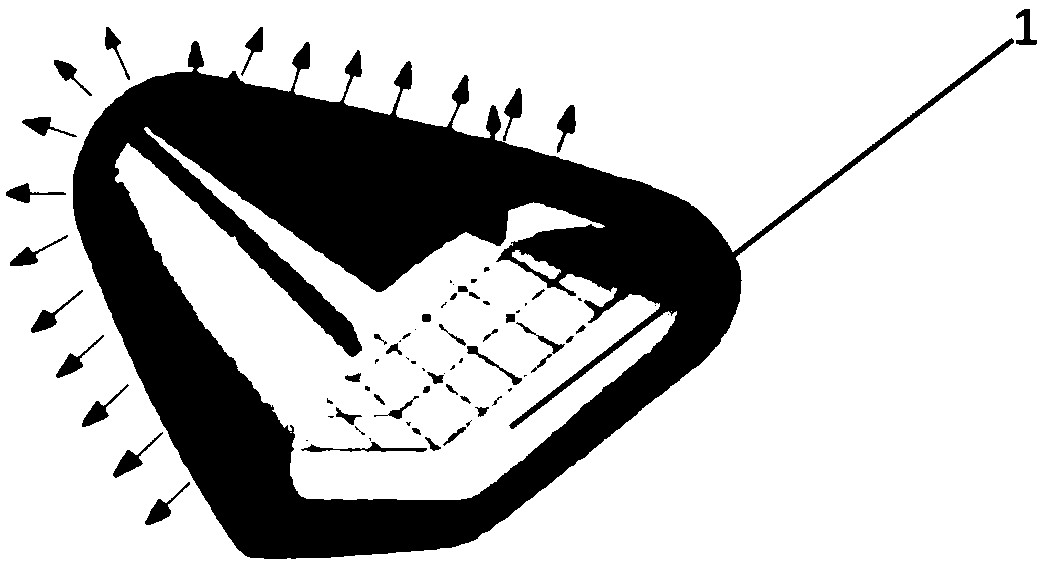

[0024] Combined thermoelectric cycle engines, such as figure 1 As shown, on the basis of the existing TBCC engine structure, increase the drive motor 2 for the turbojet engine, that is, increase the drive motor 2 in the turbojet engine; the drive motor 2 is placed in the combustion chamber 9; the drive motor 2 acts on The fixed connection shaft connecting the compressor 5 and the turbine 6; the driving force required by the compressor 5 is provided by the turbine 6 alone and becomes jointly provided by the turbine 6 and the drive motor 2 . The thermoelectric conversion material 1 is installed on the outlet wall of the nozzle of the turbojet engine to recover the waste heat of the nozzle and help the nozzle to dissipate heat, such as Figure 4 As shown; install thermoelectric material 1 at the front of the aircraft to recover the aerodynamic heat generated by the high-speed flight of the aircraft; install thermoelectric conversion material 1 at the outlet of the overall tail of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com