Metal composite electric heating device and heating furnace applying same

A metal composite and electric heating technology, applied in the field of metal composite electric heating devices and heating furnaces, can solve the problems of low effective utilization of heat, heat consumption, shortened life of heating devices, etc., to improve heat transfer efficiency and heat utilization rate. , High electrothermal conversion efficiency, and the effect of preventing heat diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

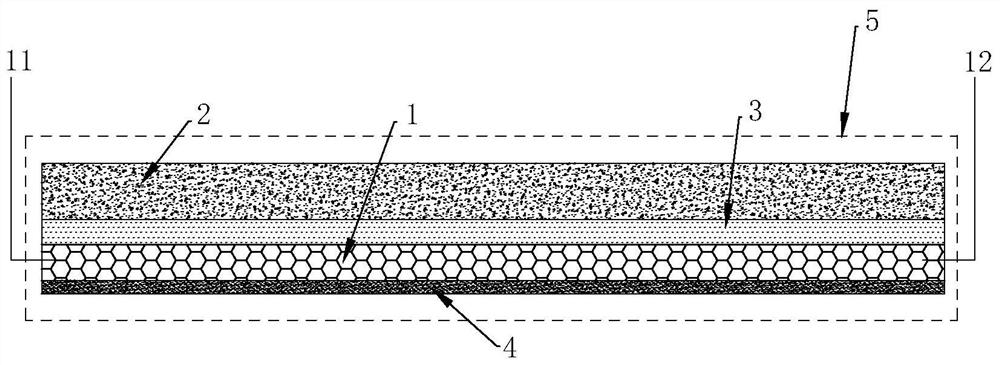

[0034] Such as figure 1 As shown, the metal composite electric heating device A of this embodiment includes an electric heating layer 1 , a metal base layer 2 , a first insulating layer 3 , and a second insulating layer 4 .

[0035] The first end of the electric heating layer 1 is connected to the first terminal 11, the second end of the electric heating layer 1 is connected to the second terminal 12, and the electric heating layer 1 is used to convert electric energy into thermal energy in the energized state . The metal base layer 2 is arranged at intervals on the first surface of the electric heating layer 1 for reducing the heat loss of the electric heating layer 1 . The first insulating layer 3 is arranged between the electric heating layer 1 and the metal base layer 2, and is used to isolate the electric heating layer 1 from the metal base layer; the second insulating layer 4 is arranged on the second surface of the electric heating layer 1, and is used to The second s...

Embodiment 2

[0049] The only difference between this embodiment and embodiment 1 is that the electric heating layer 1 in this embodiment is a graphene layer, and the graphene layer is coated on the first insulating layer 3 . The graphene layer is disposed on the first insulating layer 3 through a coating process, which is convenient for manufacturing and low in cost; the graphene layer can directly convert electrical energy into thermal energy in an electrified state, and the electrothermal conversion efficiency is as high as 95%.

Embodiment 3

[0051] This embodiment can also be as Figure 5 As shown, it is made into a very thin heating stove or frying pan, which can be directly placed on the table for use. It is light and flexible, and improves the user experience.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap