Cooking fumes purifier

A technology of oil fume purifier and purification device, which is applied in the direction of oil fume removal, chemical instruments and methods, household heating, etc., which can solve the problems of filter dirty oil clogging, oil fume cannot be drained, and unsatisfactory effect, so as to avoid pollution, Effects of environmental protection and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

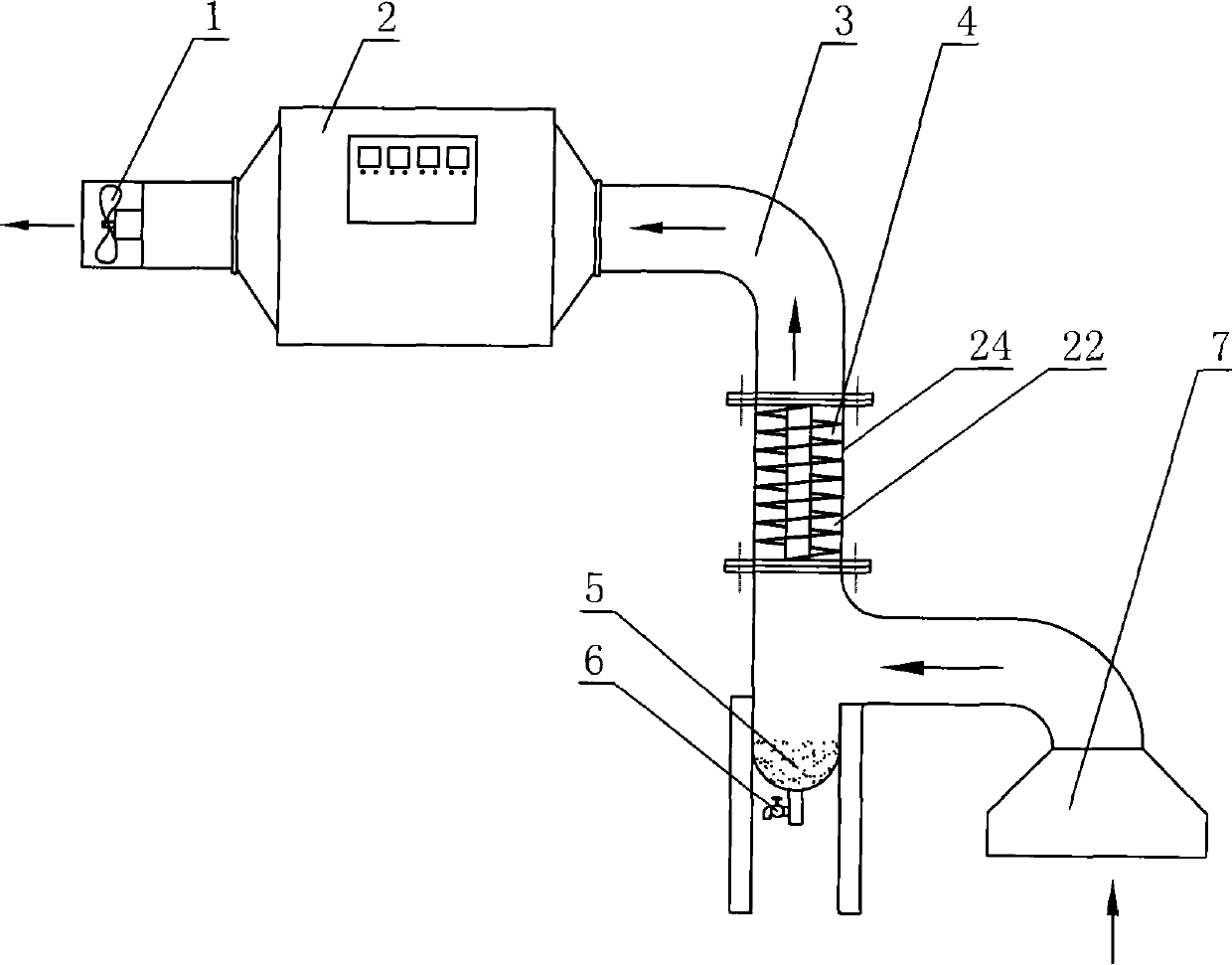

[0020] Embodiment 1 refers to figure 1 , this kind of oil fume purifier includes pipeline 3, oil fume separation device 24 and blower fan 1, and described blower fan 1 is arranged at the exit of pipeline 3, and the entrance of described pipeline 3 is connected with fume collecting hood 7, and fume collecting hood 7 The exhausted oil fume can be better absorbed into the pipeline 3. If the oil fume purifier is used for the incinerator used in the waste incineration plant, the pipeline can be directly connected to the outlet of the incinerator, so that the fume collecting hood can be omitted. The oil fume separation device 24 has a spiral passage 4, the spiral passage in the present embodiment 1 is provided with a thread 22 in the pipe 3, the outer diameter of the thread 22 matches the inner wall of the pipe, and the inner diameter of the thread 22 is A spiral channel 4 is formed with the inner wall of the pipeline, and an oil collecting tank 5 is arranged under the spiral channe...

Embodiment 2

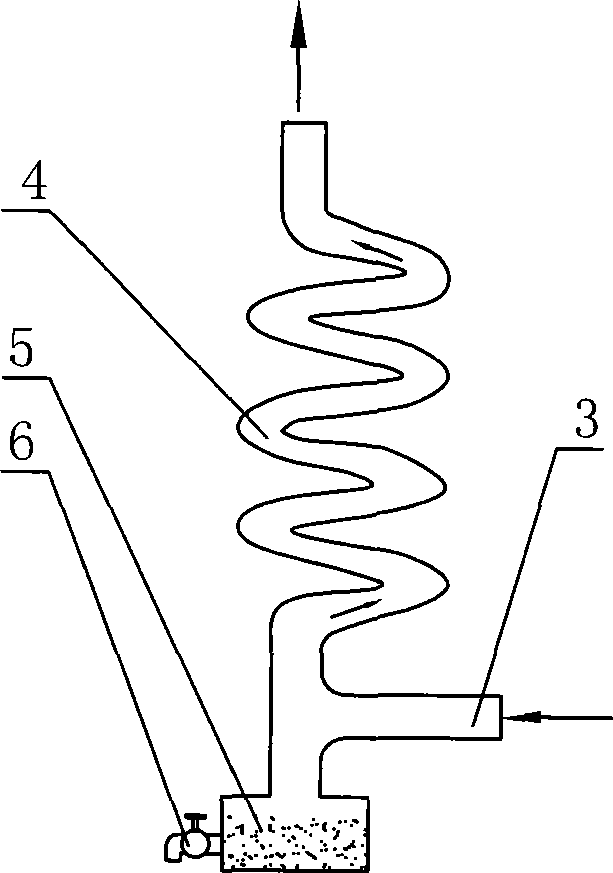

[0021] Embodiment 2, with reference to figure 2 The oil fume separation device of this kind of oil fume purifier has a spiral channel 4, and the spiral channel 4 is a hollow straw-shaped spiral channel 4, and the two ends of the spiral channel 4 communicate with the pipeline, and the spiral channel 4 An oil collecting tank 5 is arranged below the channel 4, and a discharge valve 6 is arranged on the oil collecting tank 5. In the same way as in Example 1, the oil fume produced by the incineration of objects is quickly transported to the outlet of the pipeline 3 by the blower fan 1. Due to the high speed of transmission, the oil fume moves around the suction pipe-type spiral channel 4. Due to the specific gravity of the oil pollution is higher than that of the flue gas. Large, the oil will be thrown on the inner wall of the spiral channel 4 during the rapid rotation and movement, and then flow to the oil collection tank 5 due to the gravity of the oil itself, and be discharged ...

Embodiment 3

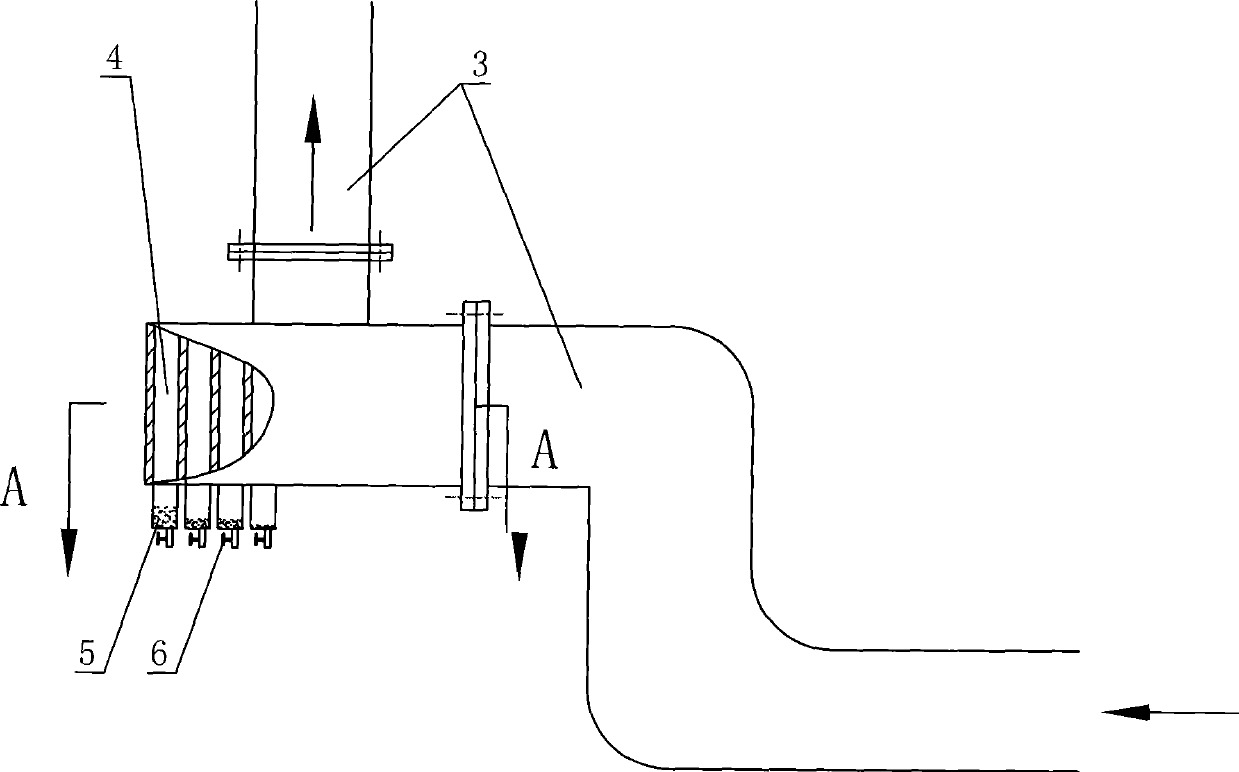

[0022] Embodiment 3, with reference to image 3 , Figure 4 The oil fume separation device of this kind of oil fume purifier has a spiral channel 4, and the spiral channel 4 is rolled by a plastic sheet or a metal sheet, just like a rolled picture scroll, its cross section is spiral, and the closed The gap formed between the rolled plastic sheets or metal sheets is the spiral channel 4, the outermost entrance and the innermost (ie its central part) exit of the spiral channel rolled by plastic sheets or metal They are respectively connected with the pipeline 3, and an oil collecting tank is arranged under the spiral passage, and a discharge valve is arranged on the oil collecting groove. Under the action of the fan 1, the oil fume moves around the spiral channel 4. Since the specific gravity of the oil stain is larger than that of the smoke, the oil stain will be thrown on the inner wall of the spiral channel 4 during the rapid rotation and movement, and the smoke The gas con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com