Burner gas condensing unit for preparing element phosphor by electric furnace process

A technology of condensing device and electric furnace method, applied in the direction of phosphorus preparation, climate sustainability, sustainable manufacturing/processing, etc., can solve problems such as short residence time, low recovery rate of elemental phosphorus, difficulty in meeting emission factors, etc., and achieve reduction Dust content, increase recovery rate, and increase the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

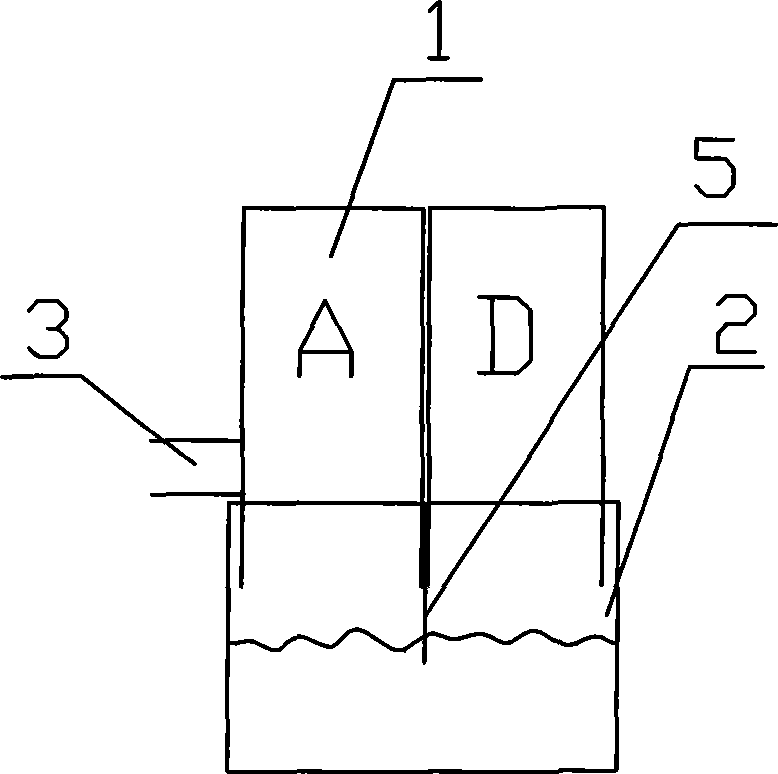

[0018] Such as figure 1 and 2 As shown, the condensing device for the furnace gas in the preparation of element phosphorus by the electric furnace method mainly includes a condensation tower 1, a phosphorus receiving tank 2, an air guide pipe 3, and an emptying pipe 4. There are holes on the phosphorus receiving tank 2, and the phosphorus receiving tank 2 There are 2 condensation towers and 1 is 4 in series, the air guide pipe 3 is connected with the lower end of the first tower A, the tower A is connected with the top of tower B, the tower B is connected with the bottom of tower C, the tower C is connected with the top of tower D, and the tail gas is discharged 4 Tower A and tower D are located in the same phosphorus receiving tank 2. If there is no communication between tower A and tower D, there is a baffle plate 5 that is sealed and connected with phosphorus receiving tank 2 to isolate tower A and tower D. The lower communication channel between tower B and tower C is loc...

Embodiment 2

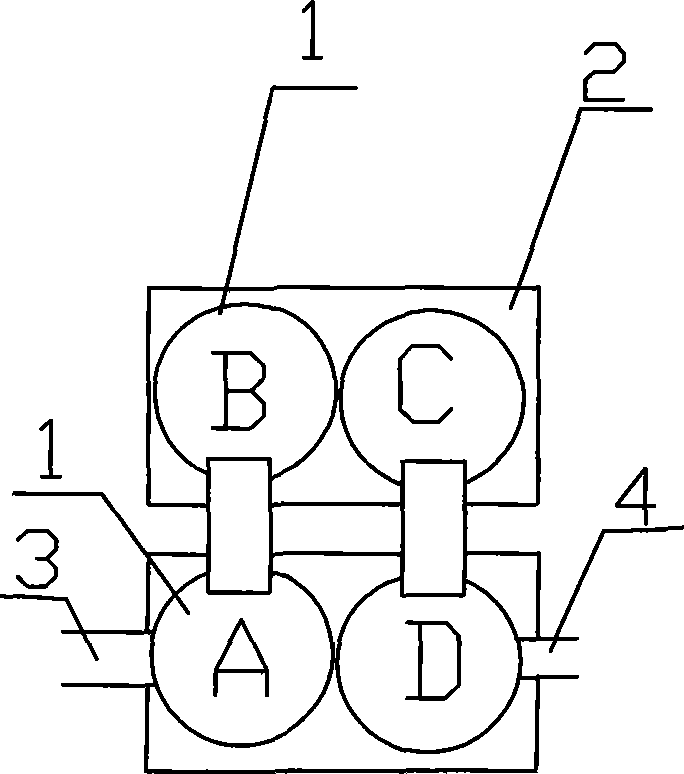

[0020] Such as figure 2 As shown, the condensing device for the furnace gas in the preparation of element phosphorus by the electric furnace method mainly includes a condensation tower 1, a phosphorus receiving tank 2, an air guide pipe 3, and an emptying pipe 4. There are holes on the phosphorus receiving tank 2, and the phosphorus receiving tank 2 It is one, the air guide pipe 3 is connected to the first tower A, the emptying pipe 4 is connected to the tail tower F, and the condensation tower 1 is 6 in series, tower A and tower B, tower C and tower D, tower E and tower F are all on the top China Unicom, between tower A and tower B, tower C and tower D, tower E and tower F, there are baffles and phosphorus receiving tanks sealed connection, between tower B and tower C, tower D and tower C are all through the phosphorus receiving tank Download China Unicom. All the other are with embodiment 1.

Embodiment 3

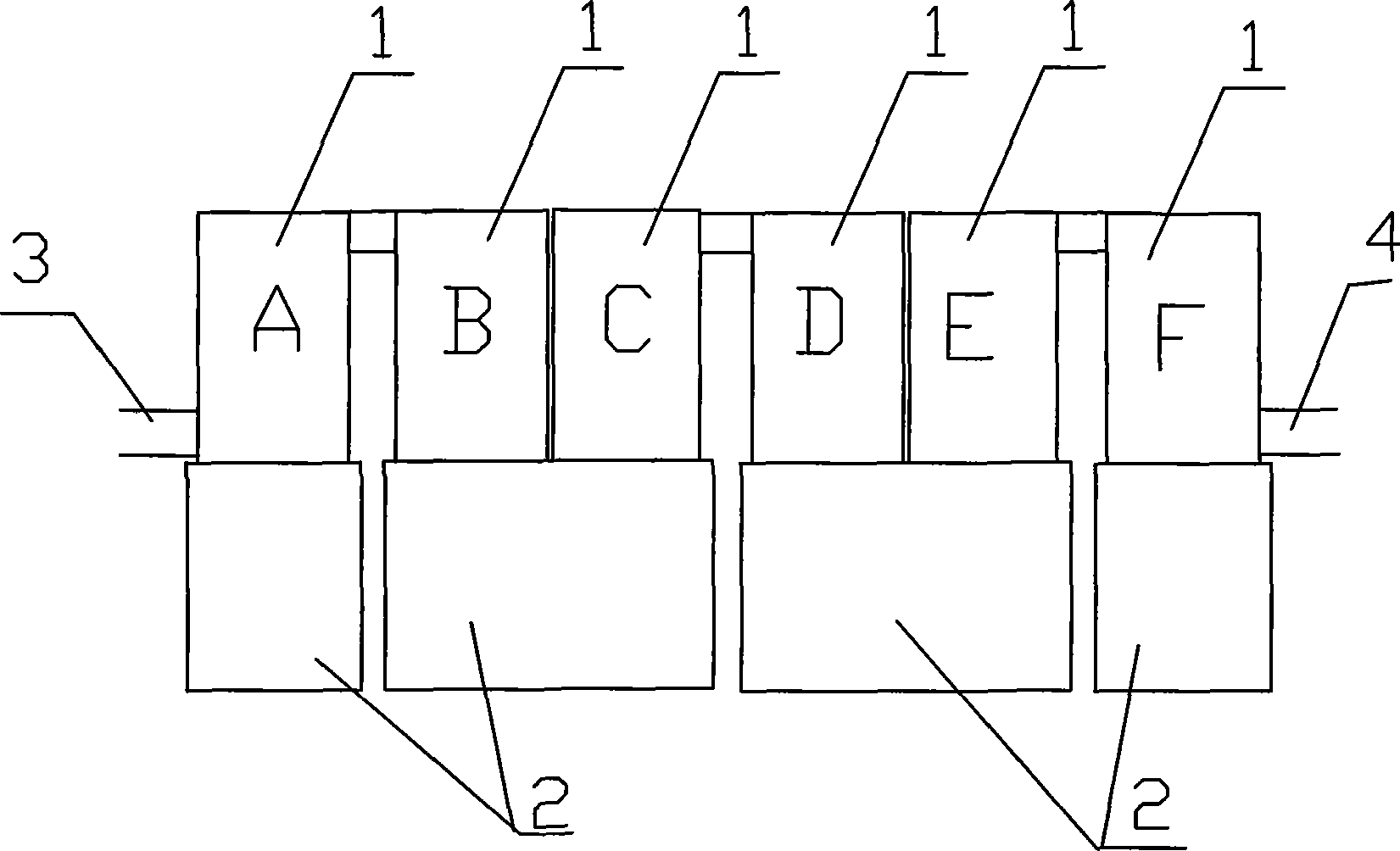

[0022] Such as Figure 4 As shown, the condensing device for the furnace gas in the preparation of element phosphorus by the electric furnace method mainly includes a condensation tower 1, a phosphorus receiving tank 2, an air guide pipe 3, and an emptying pipe 4. There are holes on the phosphorus receiving tank 2, and the phosphorus receiving tank 2 One, condensing tower 1 is 7 in series, tower A and tower B, tower C and tower D, tower E and tower F are all connected upwards, tower B and tower C, tower D and tower C, tower F and tower G The bottom of tower A communicates with one phosphorus receiving tank separately through three phosphorus receiving tanks. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com