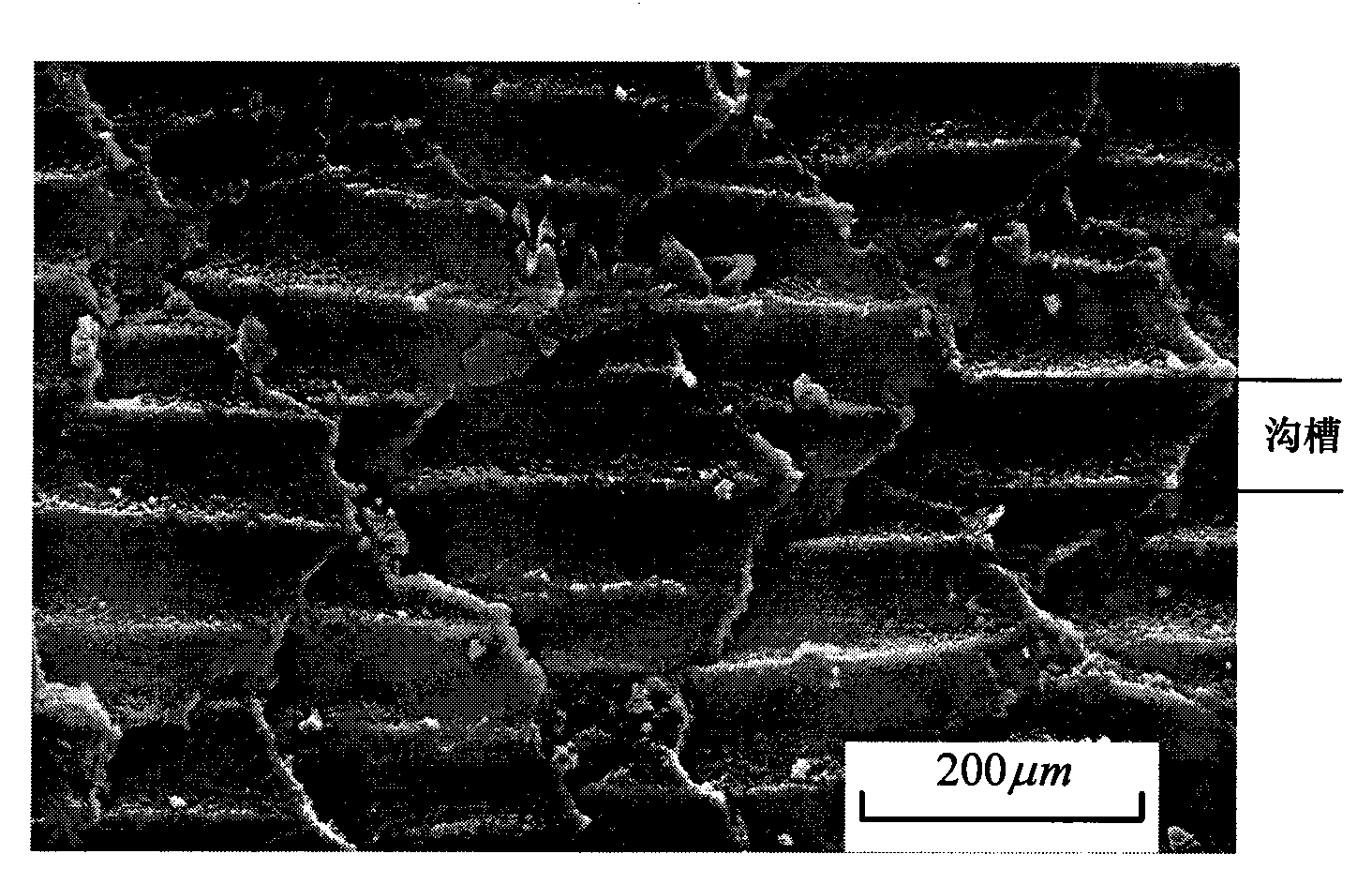

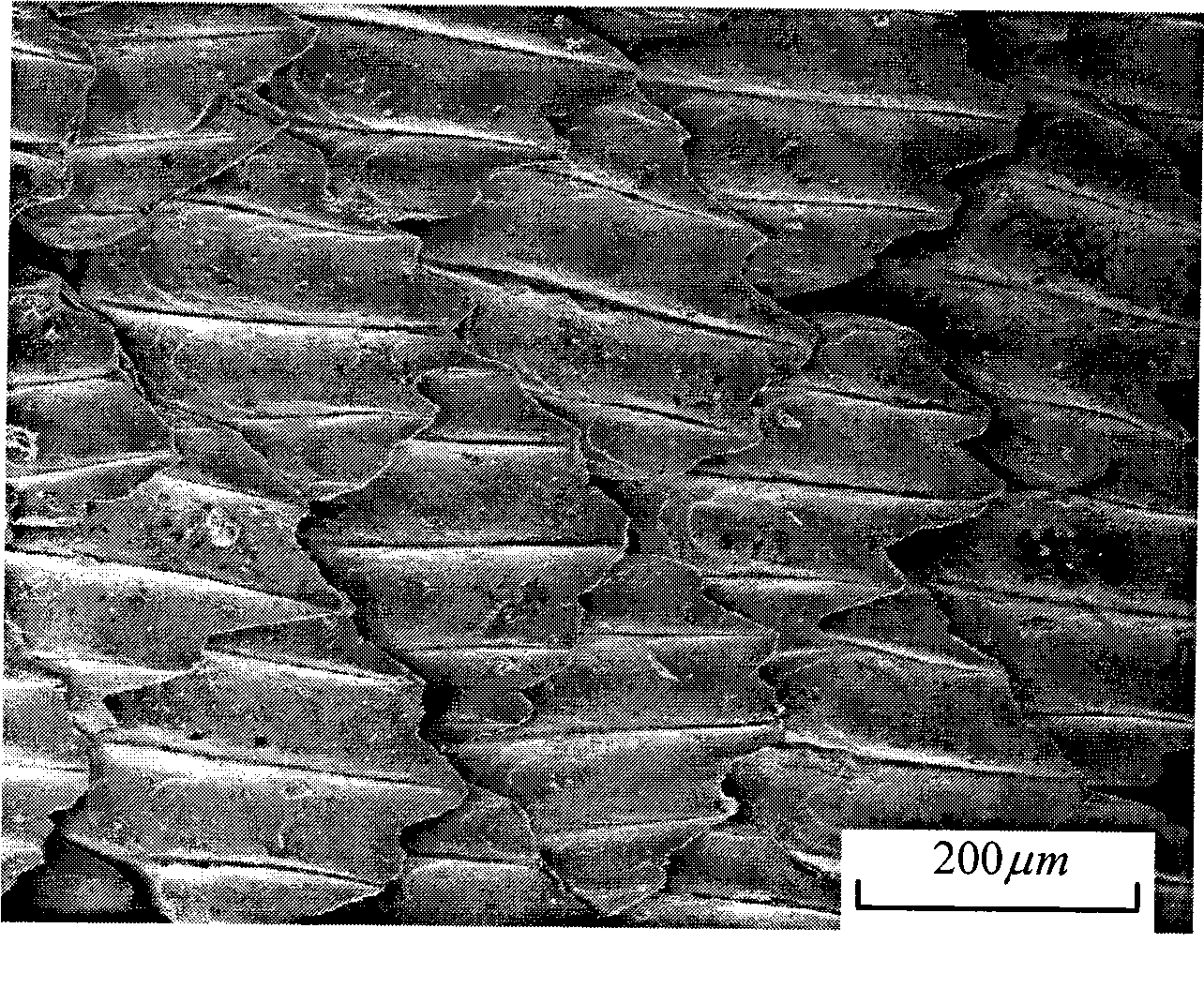

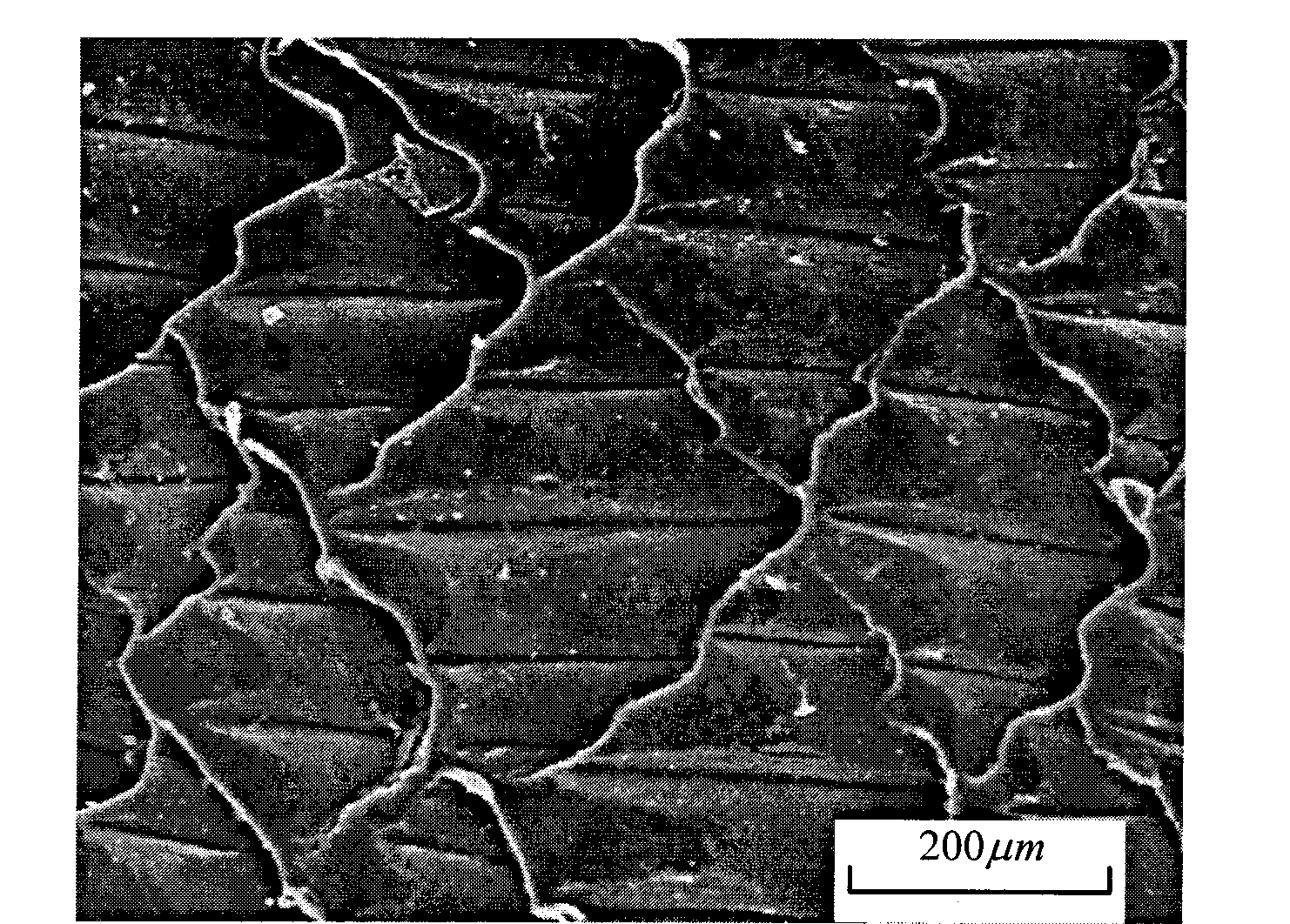

Manufacturing method of shark intimating covering having self-lubricating groove and composite anti-drag function

A technology of imitating sharks and skins, applied in coating and other directions, can solve the problems of increased drag reduction rate, poor functional effect, large waste of drag reducing agent, etc., and achieve the effect of improving drag reduction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Selection of raw materials: The silicone rubber is RTV-2-7055 silicone rubber prepolymer and 25# curing agent produced by Shenzhen Weijia Silicone Co., Ltd., and the mixing ratio is 10:1. The water-based epoxy resin is selected from AB-EP-44 water-based epoxy resin emulsion and AB-HGF water-based epoxy resin curing agent produced by Zhejiang Anbang New Material Development Co., Ltd.

[0046] The first step: making the negative mold

[0047] (A) Silicone rubber is evenly coated on the shark skin to form a female mold preform, and the thickness of the coated silicone rubber is 1.5mm;

[0048] (B) Put the female mold preform into the vacuum chamber and evacuate to 1.4×10 -4MPa, keep it for 20 minutes and take it out; pressurize and cure for 240 minutes at a pressure of 5000Pa and a curing temperature of 30°C, and then demould to obtain a female mold with a shark skin appearance;

[0049] The vacuum chamber is the PZT-6020 intelligent vacuum drying oven produced by Shangh...

Embodiment 2

[0064] Selection of raw materials: The silicone rubber is RTV-2-7055 silicone rubber prepolymer produced by Shenzhen Vega Silicone Co., Ltd. and 25# curing agent, and the mixing ratio is 15:1. The water-based epoxy resin is selected from AB-EP-44 water-based epoxy resin emulsion and AB-HGF water-based epoxy resin curing agent produced by Zhejiang Anbang New Material Development Co., Ltd.

[0065] The first step: making the negative mold

[0066] (A) Silicone rubber is evenly coated on the shark skin to form a female mold preform, and the thickness of the coated silicone rubber is 3mm;

[0067] (B) Put the female mold preform into the vacuum chamber and evacuate to 2×10 -4 MPa, keep it for 15 minutes and take it out; pressurize and cure for 150 minutes at a pressure of 3500Pa and a curing temperature of 22°C, and then demould to obtain a female mold with a shark skin appearance;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com