Deep sea hydraulic oil tank with multiple monitoring functions

A hydraulic oil tank, deep sea technology, applied in the direction of oil supply tank device, fluid pressure actuating device, fluid pressure actuating system components, etc. Damaged electrical components, multiple functions, and the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

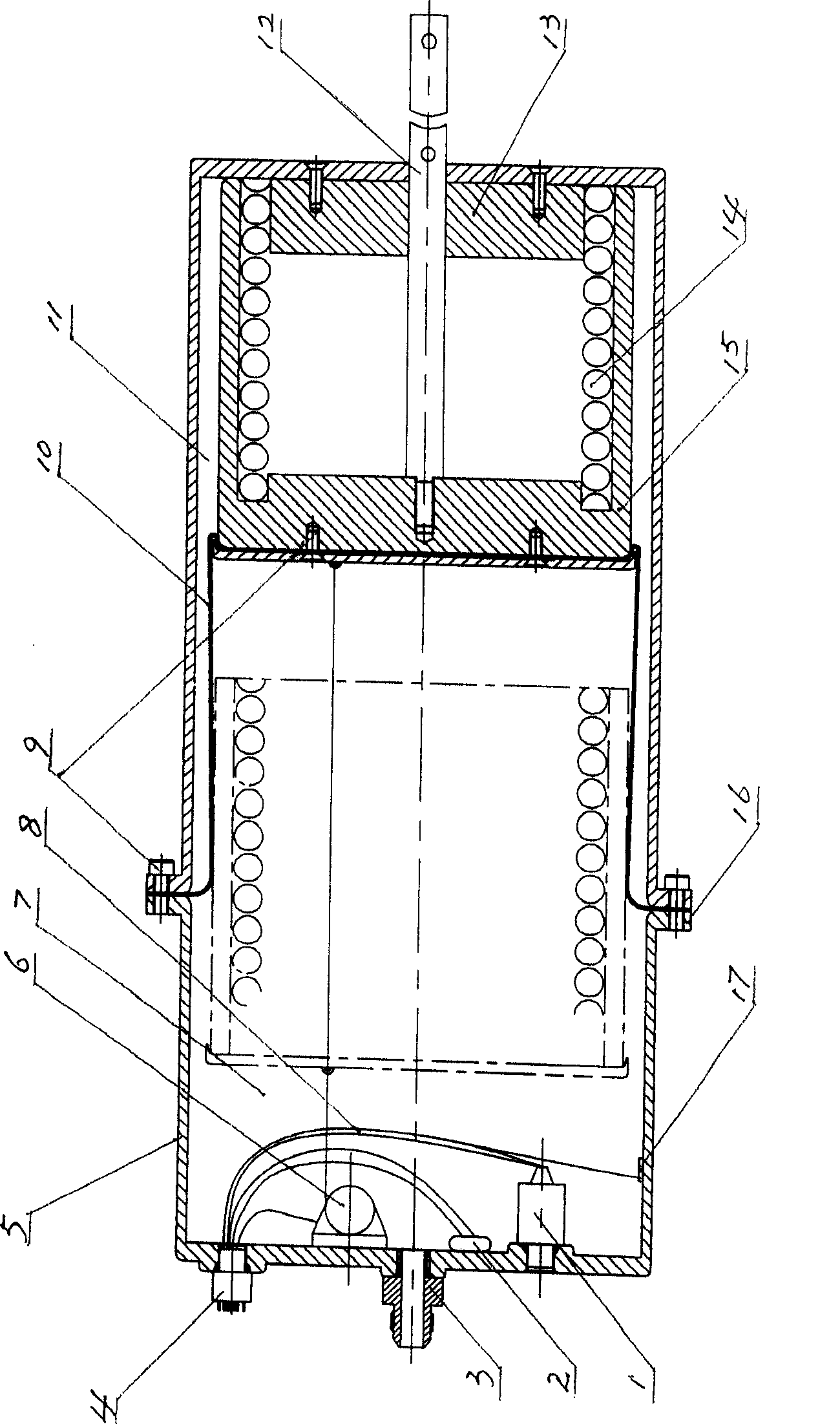

[0012] As shown in the accompanying drawings, the deep-sea hydraulic oil tank with multiple monitoring functions of the present invention includes a cylinder body 5, which is cylindrical in shape and arranged horizontally. A compensation film 10 is arranged in the middle of its inner cavity. The surroundings are fixedly connected with the inner wall of the cylinder 5 in a sealed shape, so that the cylinder 5 is divided into an oil chamber 7 and a seawater chamber 11 . A center hole is processed on the bottom of the cylinder near the oil chamber 7, and an oil circuit interface 3 is installed in the center hole, which is connected with a hydraulic oil source in the state of use. A piston 15 and a spring 14 are arranged in the seawater cavity 11 . Wherein the piston 15 is cylindrical, one end has a cylinder bottom, and the other end is open, and the end with the cylinder bottom is fixed on the compensation film 10 by means of a screw 9 . A spring seat 13 is fixed on the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com