Method for drafting differential pressure and leakage amount relation curve in leak detection of seal article

A technology of relationship curve and leakage, applied in the direction of measuring the acceleration and deceleration rate of fluid, using liquid/vacuum degree for liquid tightness measurement, etc. problem, to achieve the effect of easy implementation, high accuracy, simple and practical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

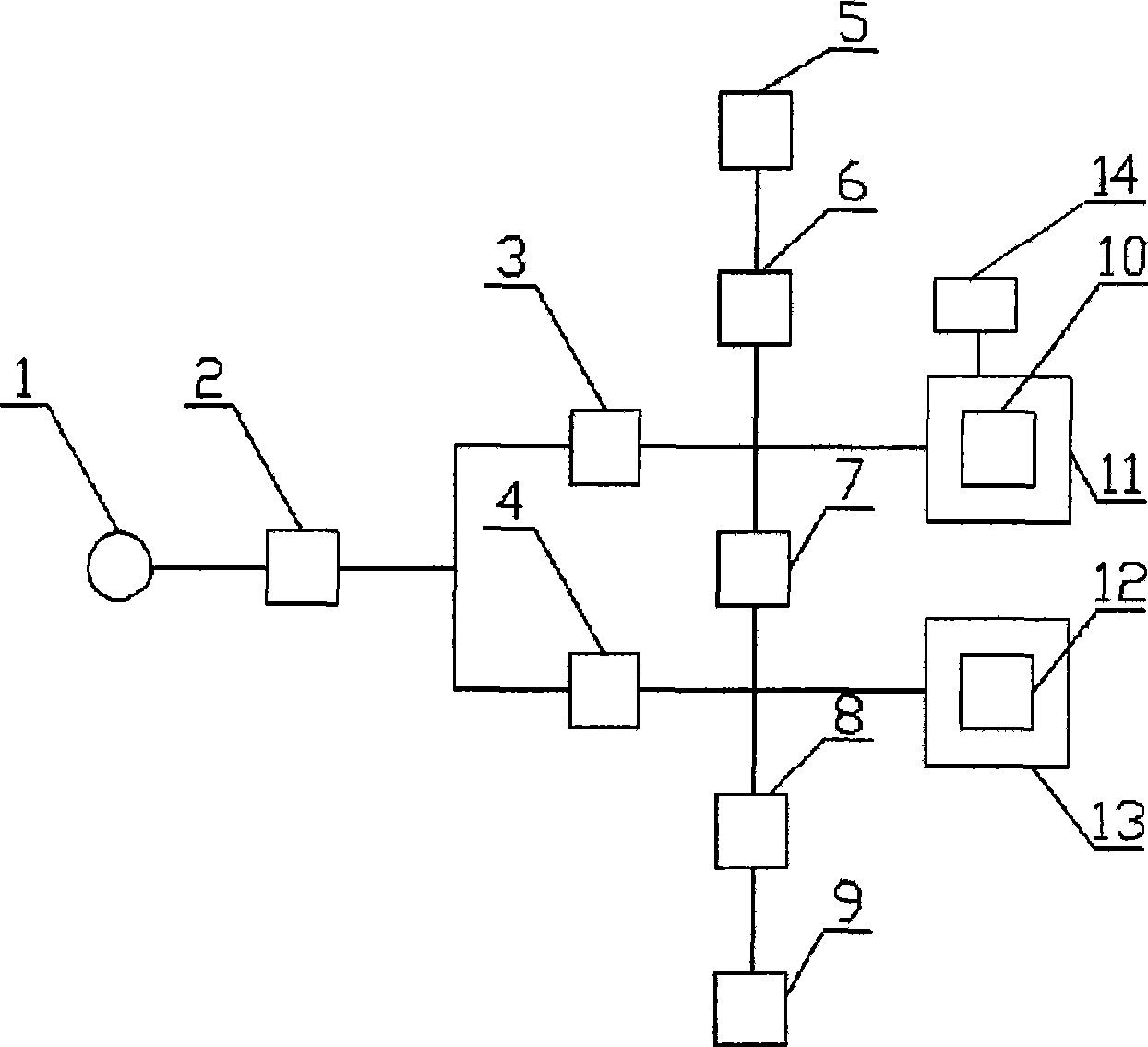

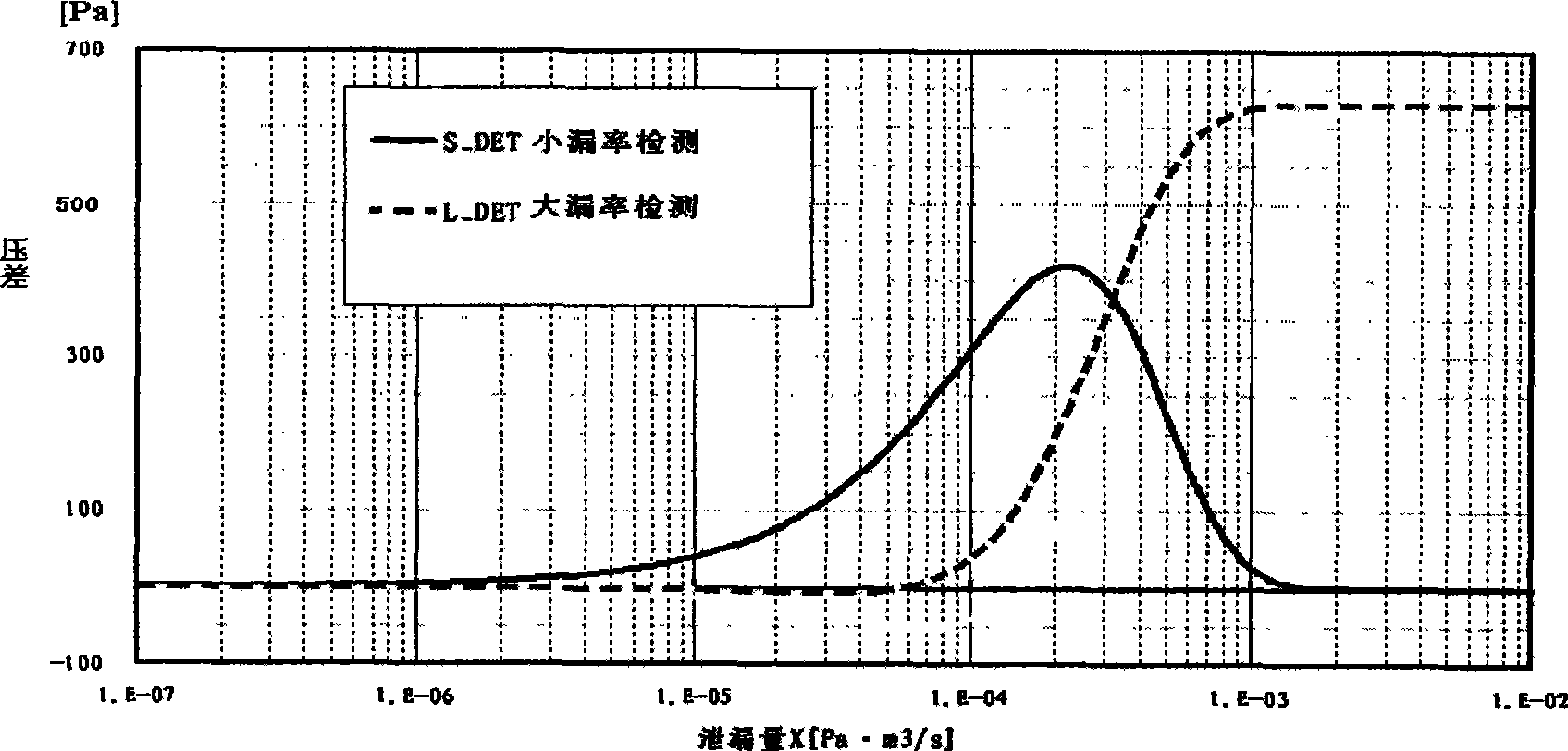

[0026] Embodiment: A method for drawing a relationship curve between pressure difference and leakage in the leak detection of sealed products, using a volume corrector product manufactured by Japan FUKUDA Company, on a differential pressure leak detection device for sealed products, and the tested part is an electronic chip. attached figure 1 It is a schematic diagram of the pneumatic circuit of the differential pressure seal leak detection device, which consists of an air source 1, a pressure charging valve 2, a first balance valve 3, a second balance valve 4, a first volume matching container 5, and a first large leak rate detection The valve 6, the differential pressure sensor 7, the second maximum leak rate detection valve 8, the second volume matching container 9, the test piece 10, the test piece sealed container 11, the reference piece 12 and the reference piece sealed container 13 are composed and passed through the tube road connection. The specific implementation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com