Nondestructive transferring method of graphene film

A technology of graphene film and transfer method, which is applied in the field of material science, can solve the problems of many colloid residues, complicated process, cumbersome procedures, etc., and achieve the effect of good transfer effect, simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

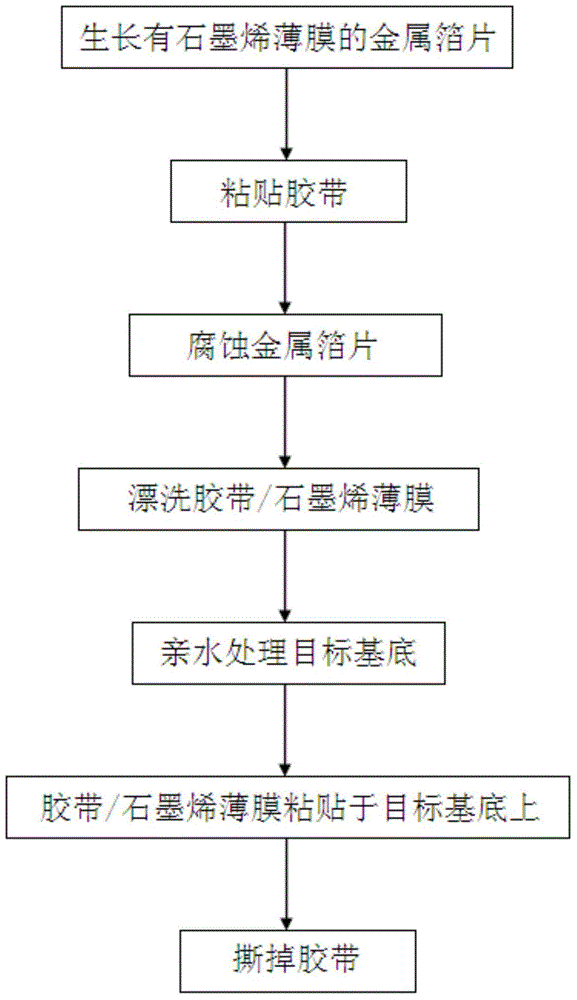

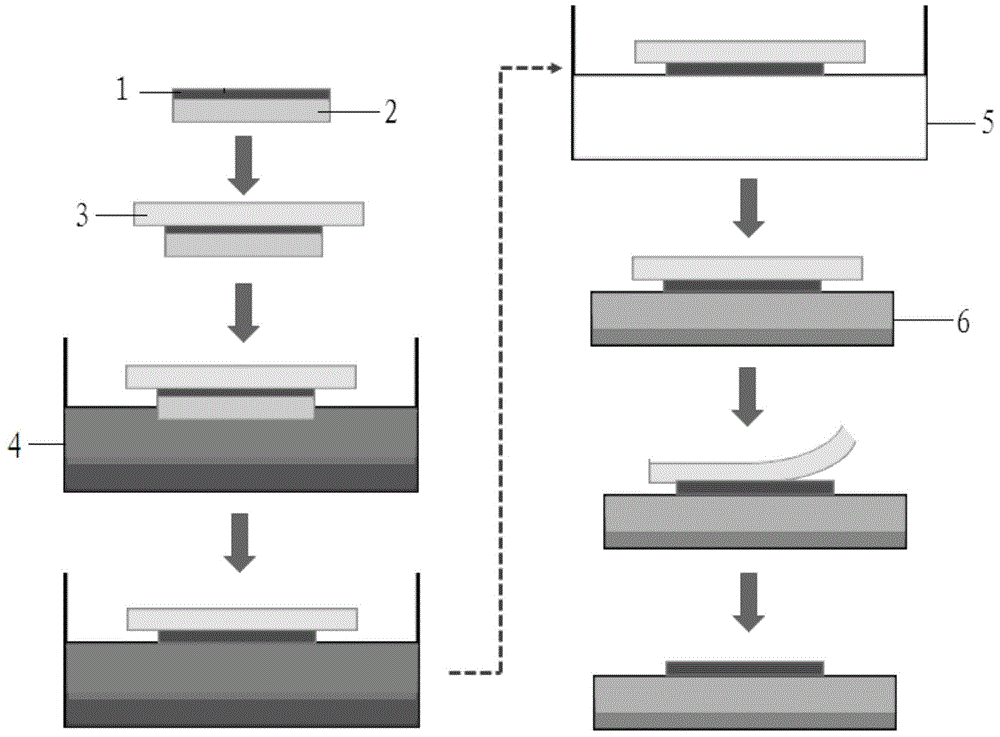

[0020] The specific steps of the graphene film non-destructive transfer method involved in this embodiment are:

[0021] (1) 1cm * 1cm or 2cm * 2cm copper foil with graphene thin film is placed flat on the glass slide, and the adhesive tape is closely attached to the copper foil surface with graphene thin film;

[0022] (2) Put the above-mentioned copper foil with adhesive tape on its surface into the ferric nitrate (Fe(NO3)3) corrosion solution with a concentration of 0.1-0.5g / ml to corrode for 2-10h, and remove the copper foil substrate to obtain the adhesive tape / graphene The film structure, the adhesion between the tape and the graphene is sufficient to make the tape a support for the graphene film;

[0023] (3) Pick up the adhesive tape / graphene film structure gently and put it into a petri dish equipped with deionized water to rinse for 10-30min, repeat this rinsing process 3-5 times; Hydrophilic treatment is carried out on the surface of the target substrate for 3-5 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

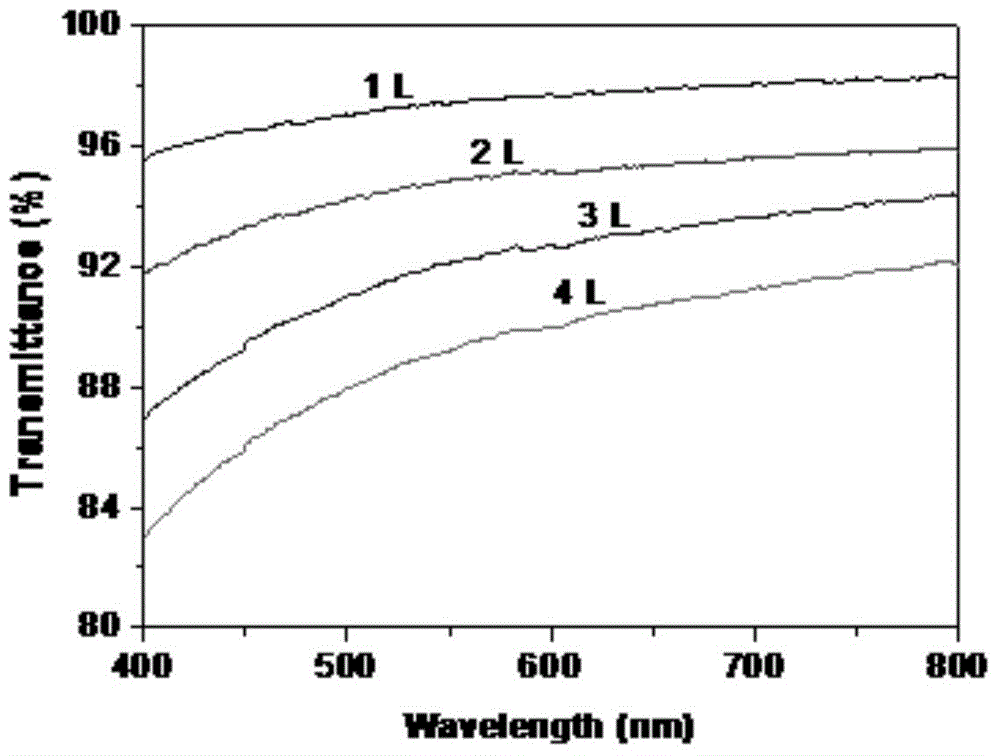

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com