Fuel cell tester

A fuel cell and tester technology, which is applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problems of inconvenient data collection, rough measurement, low test efficiency, etc., to improve development efficiency, flexible and convenient testing, and reliable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

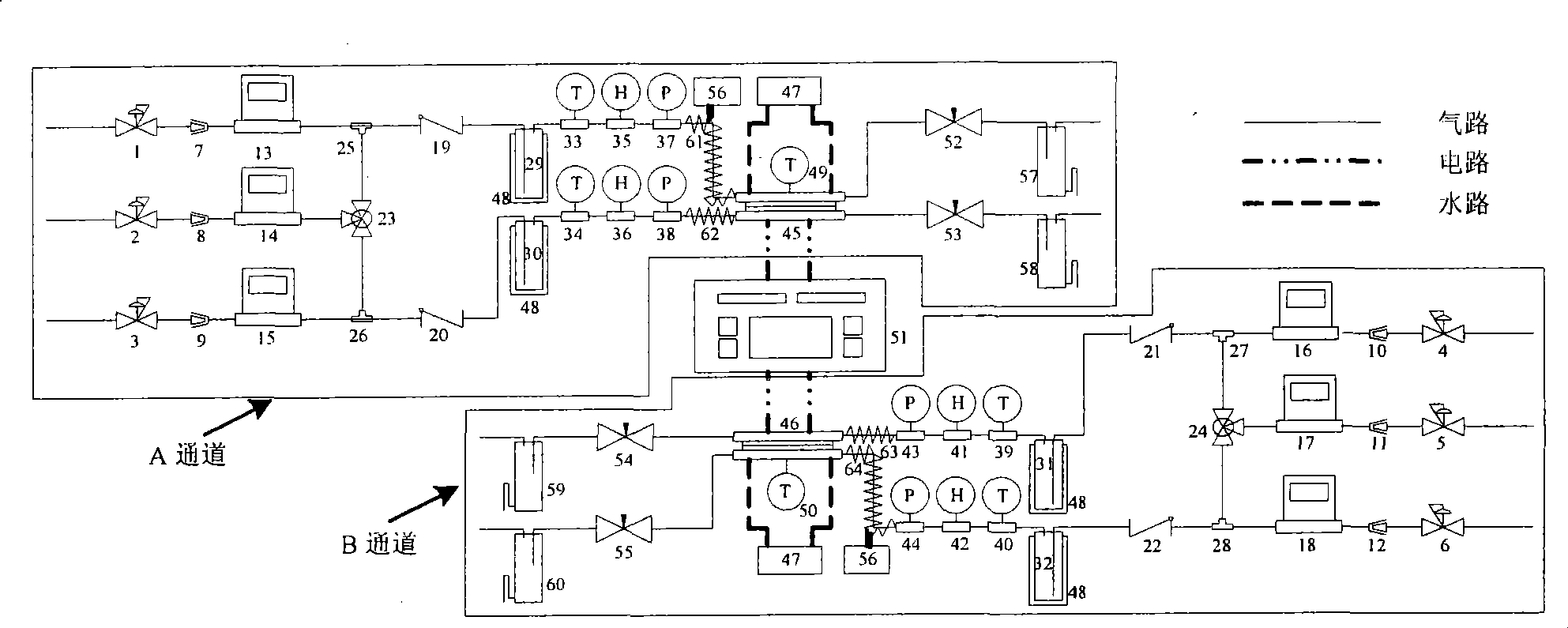

[0018] The present invention will be further described below in conjunction with a dual-channel embodiment shown in the accompanying drawings.

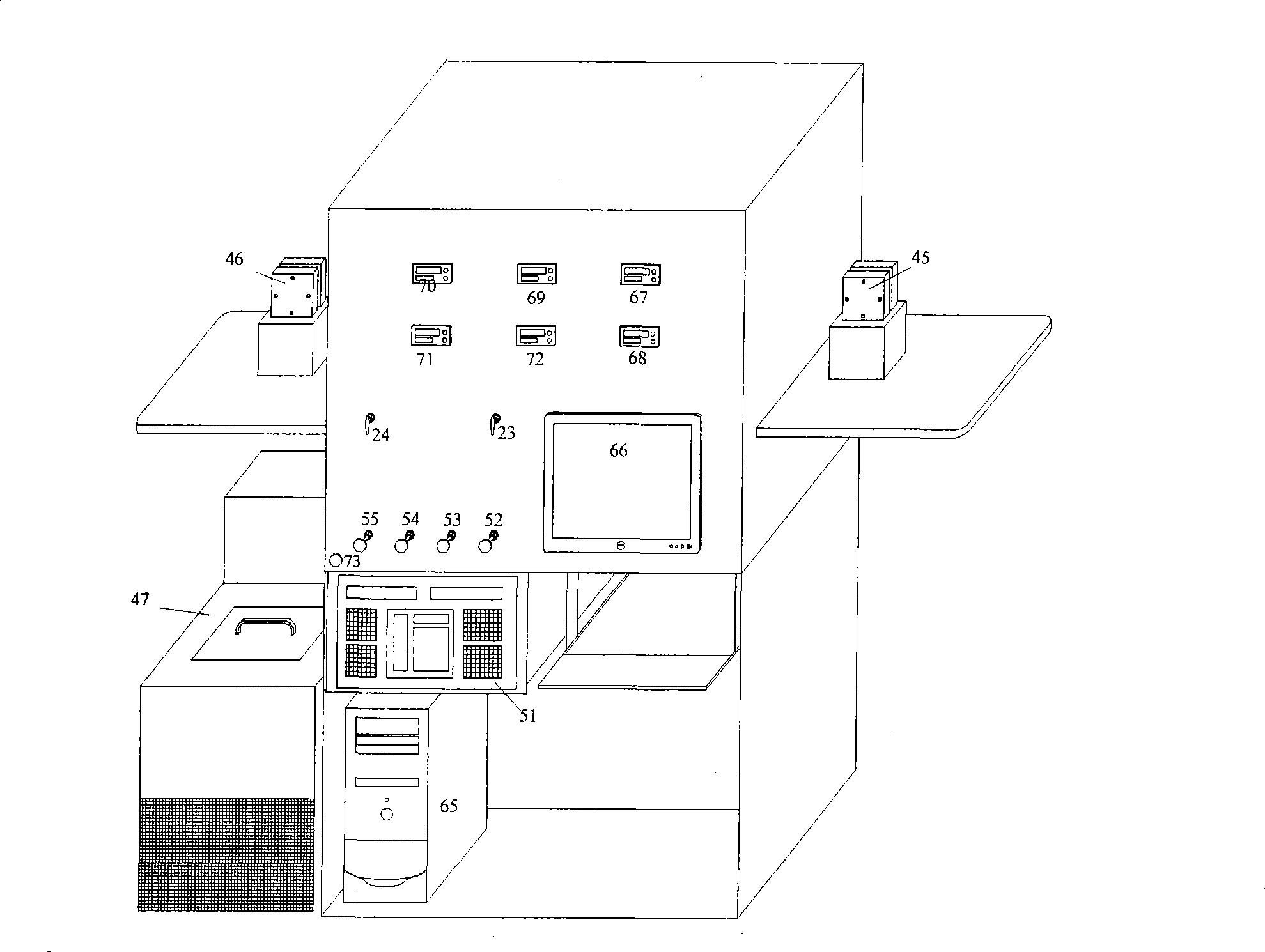

[0019] figure 1 Medium, 1~6 pressure reducing valve; 7~12 quick connector; 13~18 mass flow controller; 19~22 check valve; 23~24 three-port ball valve; 25~28 tee; 29~32 humidifier; 33~34, 39~40, 49~50 temperature sensor; 35~36, 41~42 humidity sensor; 37~38, 43~44 pressure sensor; 45~46 battery (stack) to be tested; 47 constant temperature water tank; 48 constant temperature Oil bath; 51 electronic load; 52-55 needle valve; 56 transformer; 57-60 steam-water separator; 61-64 heating belt; 65-66 computer; 67-72 display instrument; 73 emergency stop button. Among them, components 1, 2, 3, 7, 8, 9, 13, 14, 15, 19, 20, 23, 25, and 26 form a flow control unit; 29, 30 form a humidification unit; 33, 34, 35, and 36 , 37, 38, 49 form the signal acquisition unit; 47 is the temperature control unit; 45, 51 form the discharge unit; the auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com