Ultrasound motor drive controller based on embedded system level chip

An embedded system and drive controller technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of complex motor control and achieve stable motor speed , the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

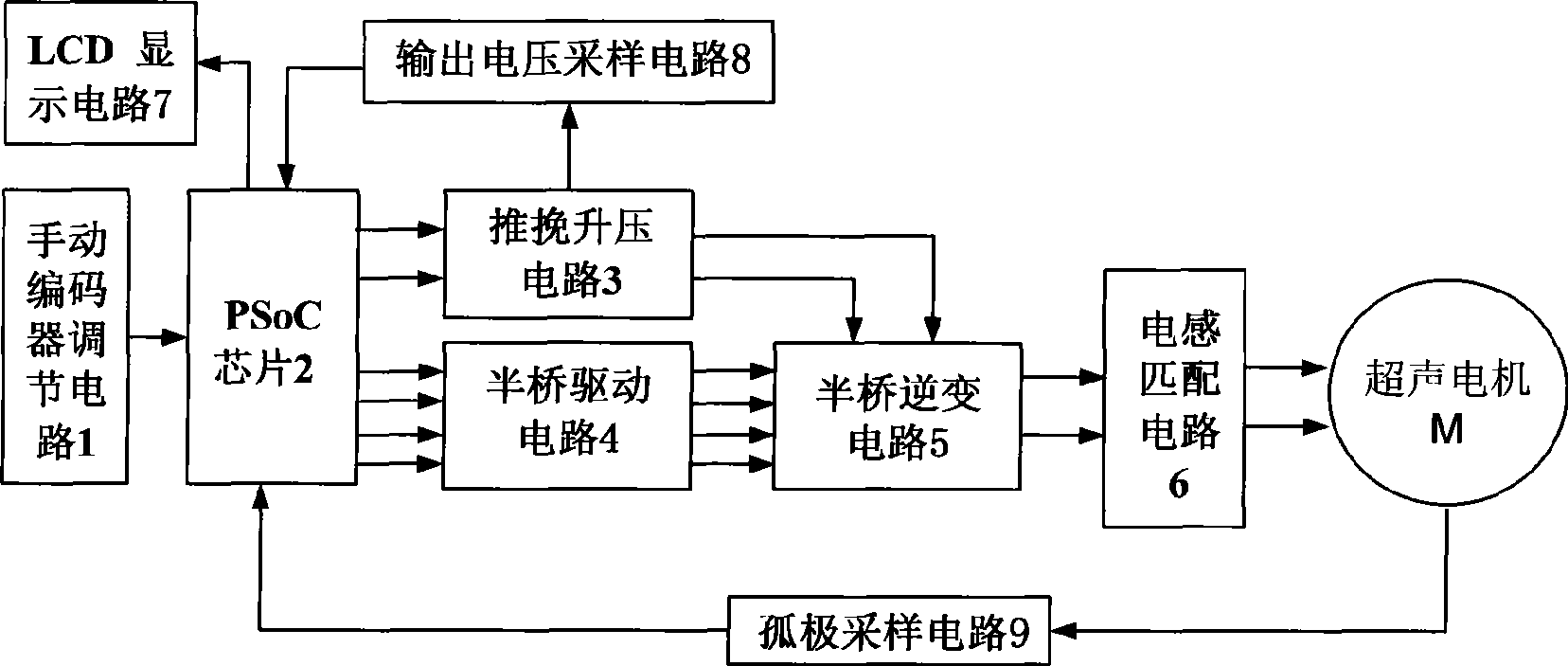

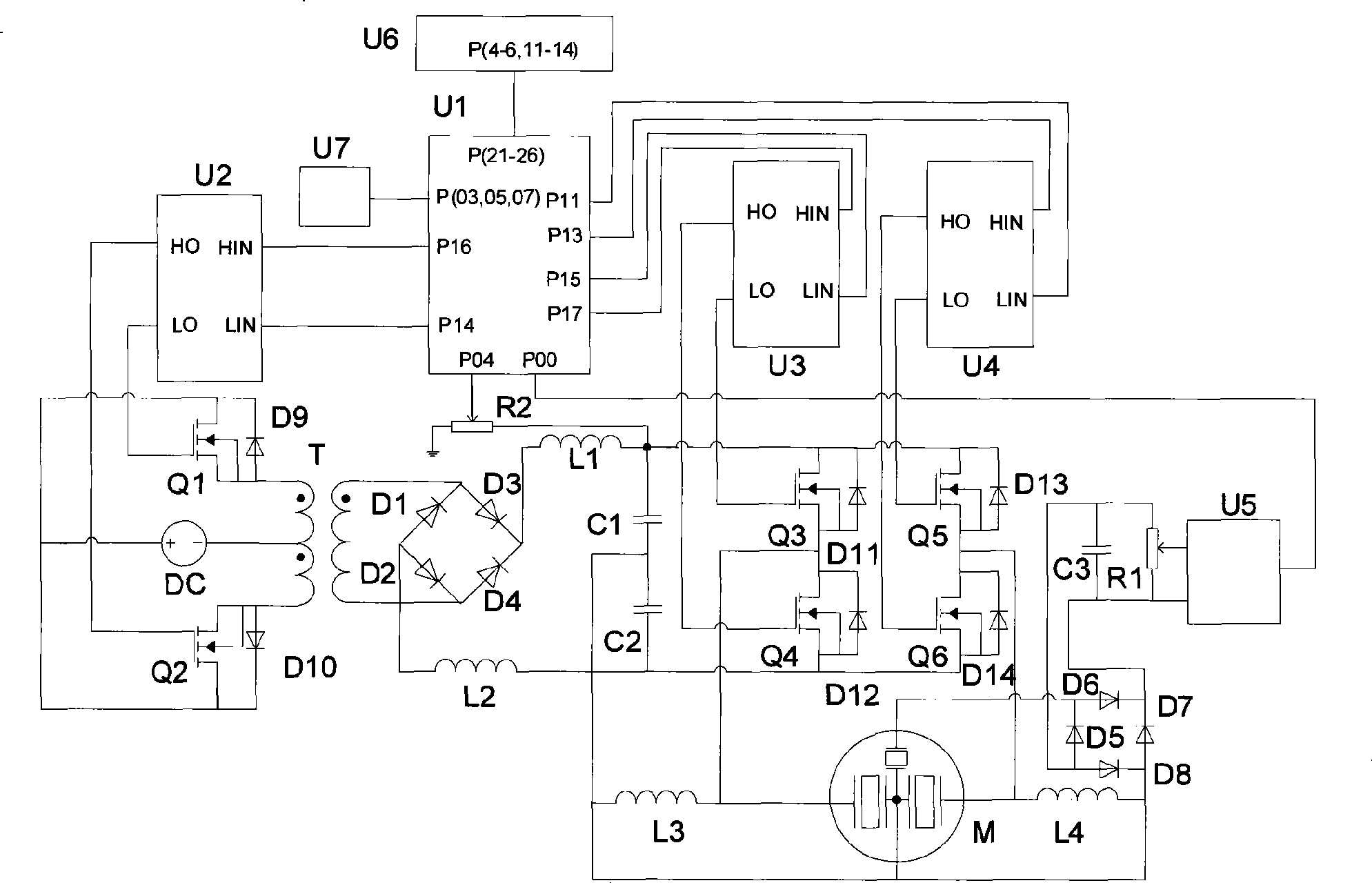

[0018] Such as figure 1 As shown, an ultrasonic motor drive controller based on an embedded system-level chip includes a manual encoder adjustment circuit 1, a PSoC chip 2, an inductance matching circuit 6, and an LCD display circuit 7, wherein the output terminal of the manual encoder adjustment circuit 1 is connected to The input terminal of PSoC chip 2, the output terminal of PSoC chip 2 is connected to the input terminal of LCD display circuit 7, the output terminal of inductance matching circuit 6 is connected to ultrasonic motor M, it is characterized in that also comprising push-pull boost circuit 3, half-bridge drive circuit 4. The half-bridge inverter circuit 5, the output voltage sampling circuit 8, and the isolated pole voltage sampling circuit 9, wherein the input end of the push-pull boost circuit 3 and the input end of the half-bridge drive circuit 4 are respectively connected to the output end of the PSoC chip 2, The output terminals of the push-pull boost circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com