Method for measuring clearance between metal bodies by capacity sensor

A capacitive sensor and metal body technology, applied in the field of measurement, can solve the problems of low detection accuracy and slow detection speed, and achieve the effect of high detection accuracy and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

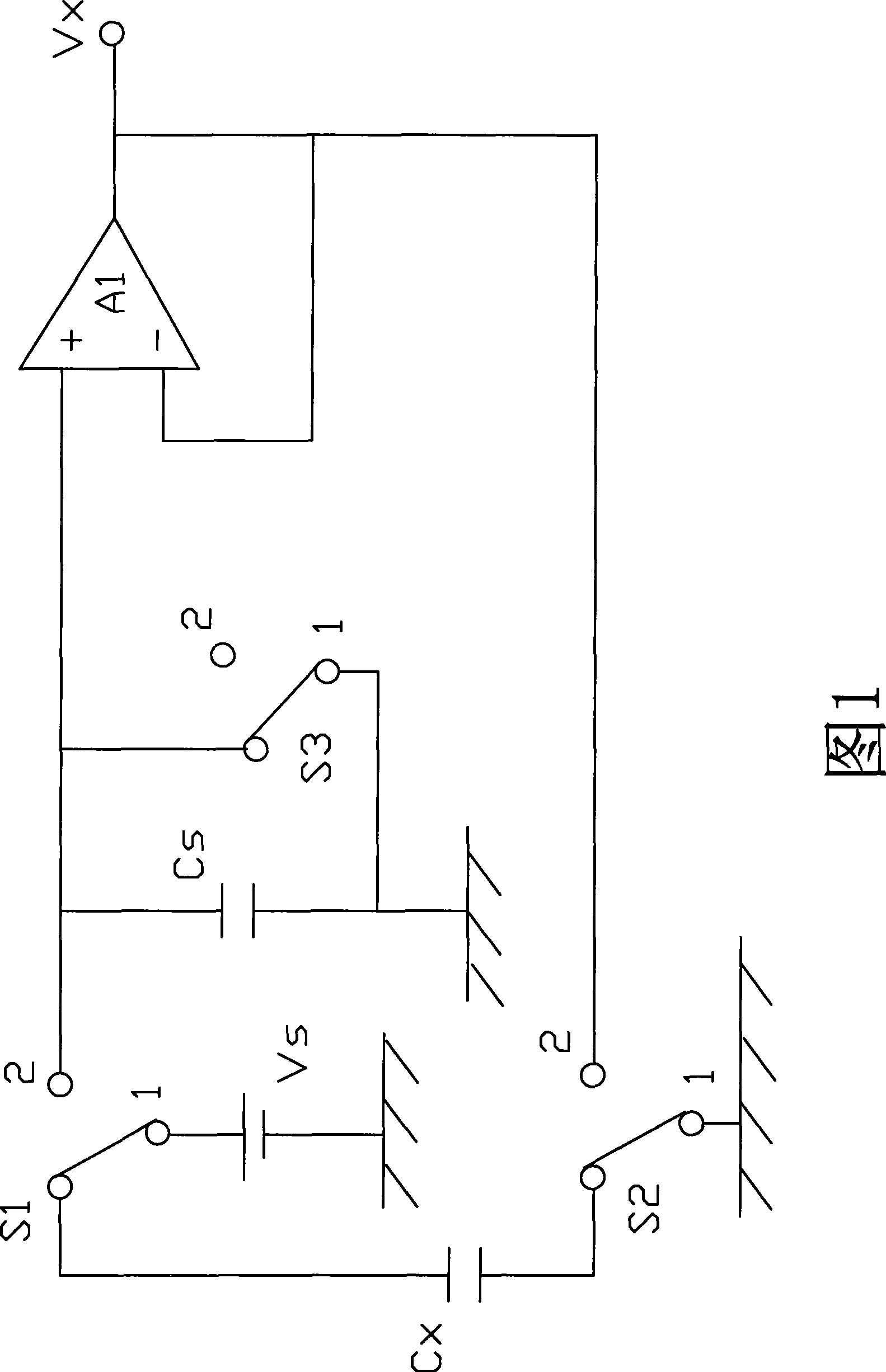

[0019] A method of utilizing a capacitive sensor to measure the gap between metal bodies of the present invention utilizes the principle of capacitive detection gap:

[0020] When the pole piece capacitive sensor is inserted into the gap between the two metal bodies, there is capacitance C1 between the sensor pole piece and the upper metal body, and there is capacitance C2 between the sensor pole piece and the lower metal body.

[0021] When two capacitors C1 and C2 are connected in series, the series capacitor C can be calculated by formula (1).

[0022] 1 / C=1 / C1+1 / C2 (1)

[0023] in

[0024] C1=εS / d1, C2=εS / d2 (2)

[0025] S: the area of the pole pieces covering each other, m 2 ;

[0026] d1, d2: respectively the distance between C1 and C2 plates, m;

[0027] ε: The dielectric constant of the medium between pole pieces, F / m.

[0028] Put formula (2) into formula (1), then:

[0029] C=εS / (d1+d2) (3)

[0030] And d1+d2 is the gap d between the two metal bodies. It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com