Bidirectional magnetism-driven generating set

A power generation device and magnetic drive technology, applied in electromechanical devices, electrical components, etc., can solve the problems that the magnetic drive power generation device cannot work normally, it is difficult to popularize and apply, and the power generation efficiency is low, so that the energy loss is small and the application range is wide , The effect of high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

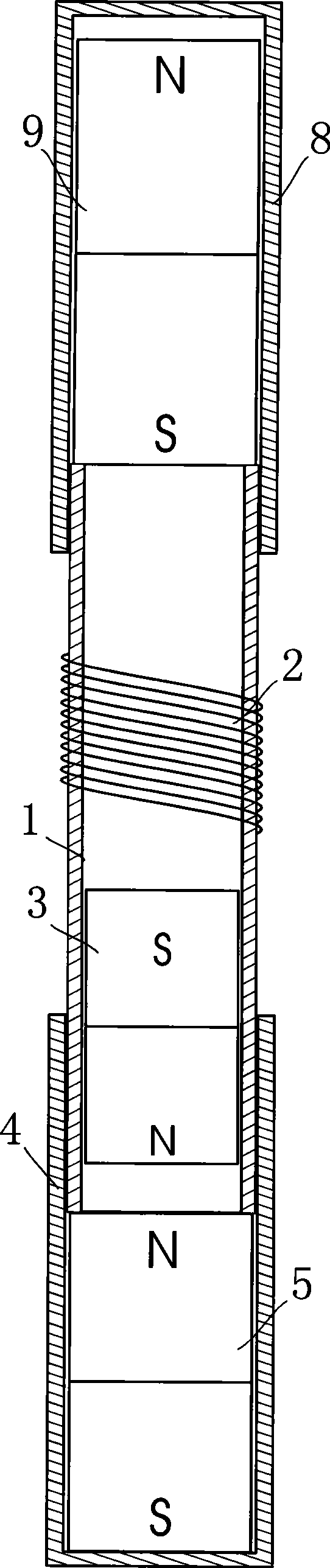

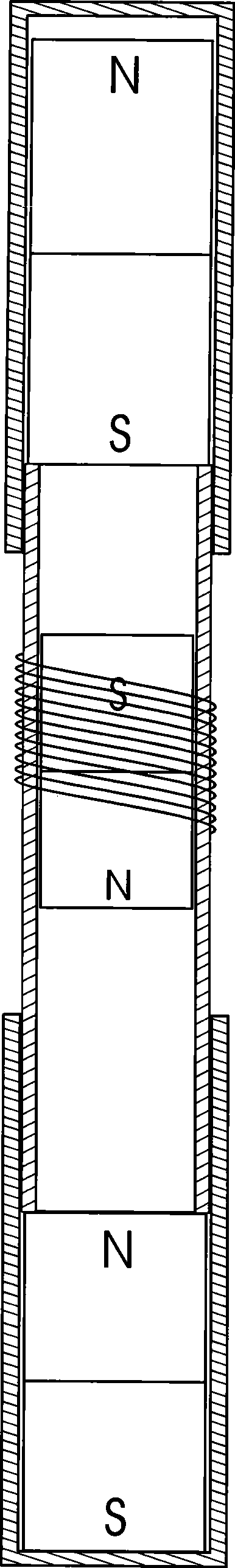

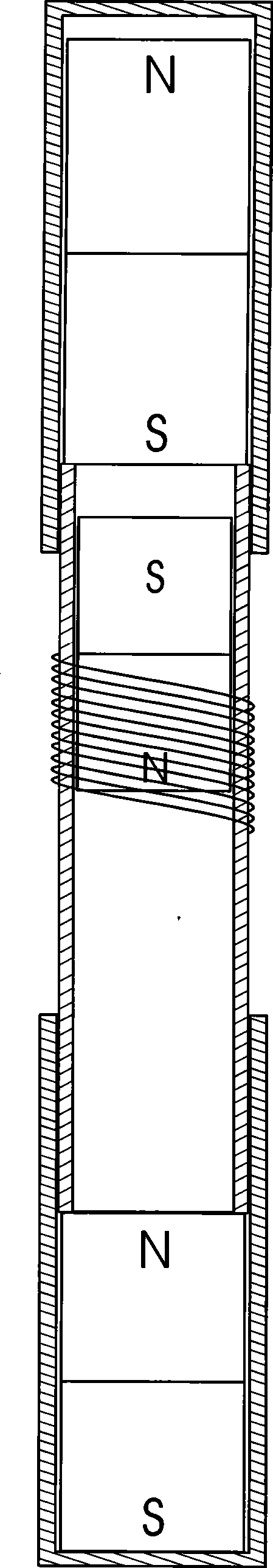

[0028] refer to Figure 1 to Figure 3 , the present invention mainly includes a cylinder body 1 and a magnetic rod 3, a wire coil 2 is wound outside the cylinder body 1, a magnet cylinder 4 is connected below the cylinder body 1, and the magnet cylinder 4 is tightly connected to the cylinder body 1, Magnet 5 is placed in described magnet cylinder 4, and magnet 5 is fixed in magnet cylinder 4, and the two ends of described magnetic bar 3 and the magnet 5 in described magnet cylinder 4 all have magnetic pole N pole and S pole respectively, Similarly, the two ends of the magnetic bar 3 also have magnetic poles N and S respectively, and the lower end of the magnetic bar 3 is opposite to the upper end of the magnet 5 in the magnet tube 4 below the cylinder body 1 . That is to say, when the lower end of the magnet bar 3 is an N pole, the upper end of the magnet 5 is also an N pole, and when the lower end of the magnet bar 3 is an S pole, then the upper end of the magnet 5 is an S po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com