Light emitting device

一种发光装置、发光元件的技术,应用在半导体器件、电气元件、电路等方向,能够解决不公知调整等问题,达到防止自吸收、提高光提取效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

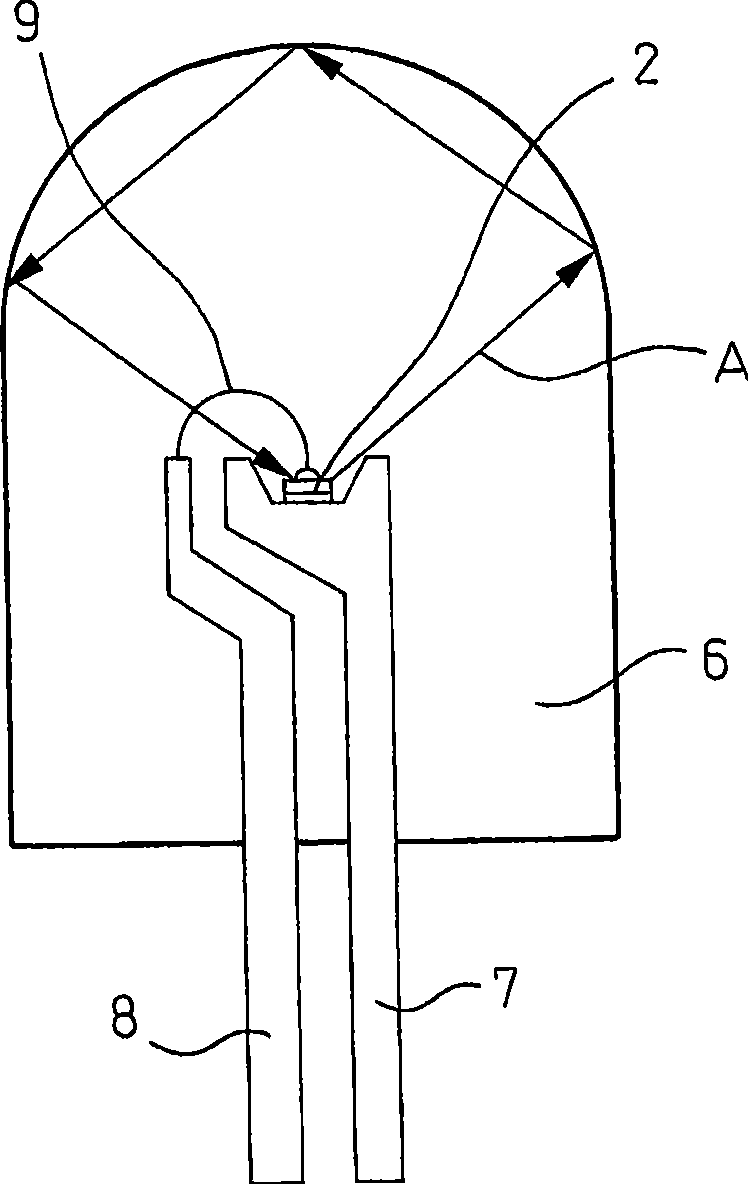

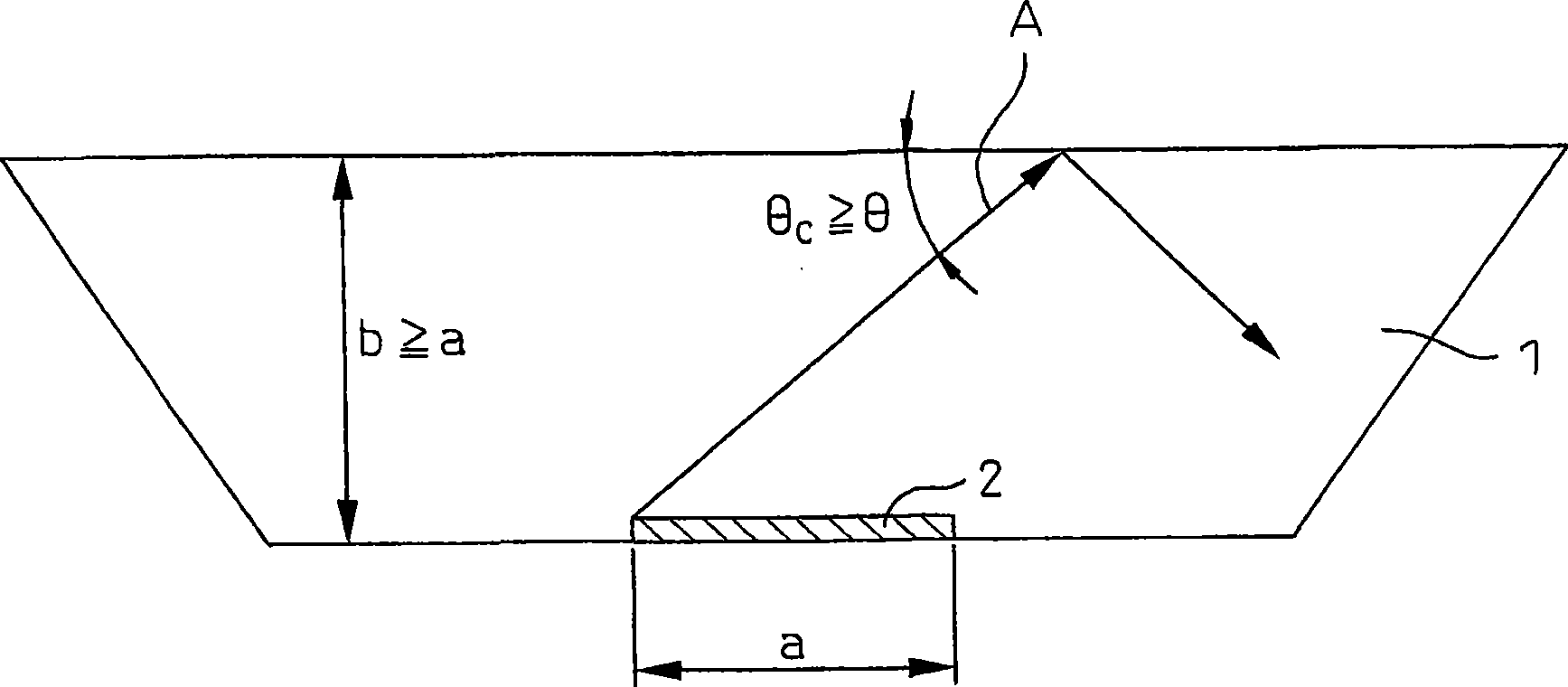

[0078] A first example of a light emitting device according to the present invention will now be described with reference to the accompanying drawings. Figure 14 is a cross-sectional view of the light-emitting device fabricated in this example, Figure 15 is a plan view of the light emitting device. The light emitting device 111 is composed of a heat sink 104 , a reflector 105 , a carrier 103 , a semiconductor light emitting element 102 and a cap 101 . Reference numeral 106 represents a sealing compound. In addition, reference numeral 120 denotes an external power supply connection electrode, and 121 denotes a heat sink mounting portion.

[0079] The used semiconductor light emitting element 102 described below is a GaN-based compound semiconductor blue light emitting element having a square shape with sides of 1 mm×1 mm and a thickness of about 90 μ.

[0080] A base layer composed of undoped GaN with a thickness of 8 μm, a Ge-doped n-type GaN contact layer with a thicknes...

example 2

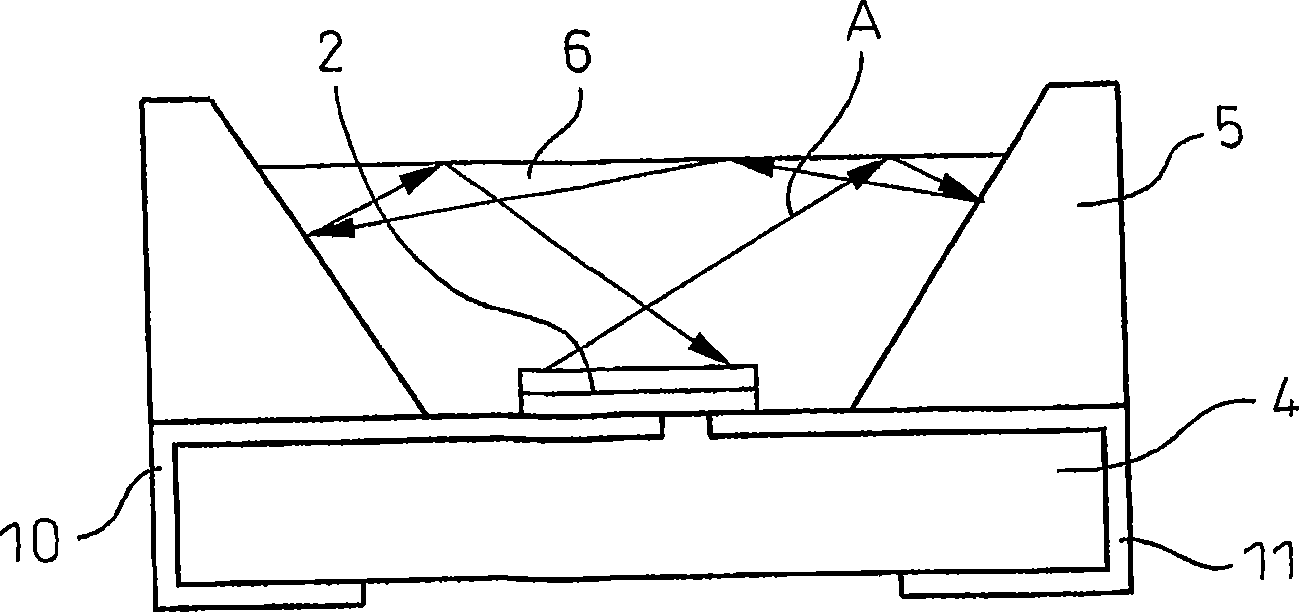

[0099] Figure 17A cross-sectional view of a light-emitting device fabricated in this example is shown. Except that the shape of the cap is a truncated conical shape, a light-emitting device was manufactured in the same manner as in Example 1, the truncated conical shape has a top surface radius of 0.8 mm, a bottom surface radius of 1.6 mm, and a height of 1.5 mm, The area ratio of the top surface to the bottom surface is 1:4 and the interval between the top surface and the bottom surface is larger than the longest diagonal of the light emitting element. When the obtained light-emitting device was subjected to a current test in the same manner as in Example 1, the light extraction was about 1.87 times that of the bare chip.

[0100] When comparing the front luminance of the light emitting device of Example 1 and the light emitting device of Example 2, the luminance of the light emitting device of Example 1 was 1, and the luminance of the light emitting device of Example 2 was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com