Workholder for multi-line cutting machine

A multi-wire cutting machine and workpiece fixture technology, which is applied in the field of workpiece fixtures, can solve the problems of wire jumping, time-consuming and labor-intensive, and broken wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

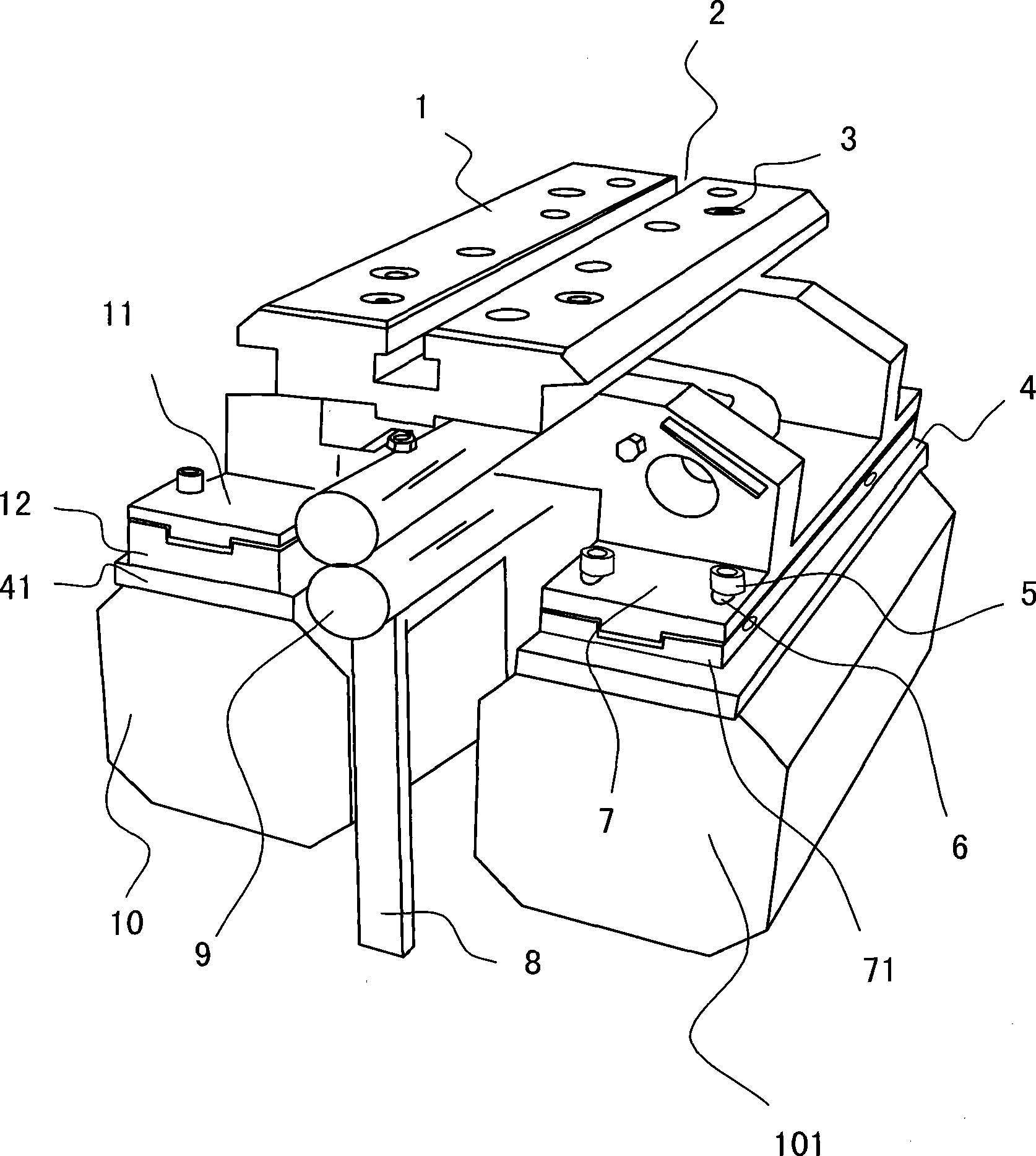

[0013] see figure 1 . The guide rail 1 passes through the loading and unloading groove 2, and is fixed on the workpiece table of the multi-wire cutting machine through the fastening screw hole 3 by fastening bolts. The clamp is symmetrical to the mortar pipe 9 below the guide rail 1, and the main connecting seat 11 and the auxiliary connecting seat 7 are respectively arranged on both sides. The main connecting piece 12 and the secondary connecting piece 71 are fixed on the main connecting seat 11 and the secondary connecting seat 7 by the corresponding positioning bolts 5 through the positioning bolt holes 6 respectively (there are corresponding corresponding positioning bolts on the main connecting piece 12 and the secondary connecting piece 71). round bolt holes).

[0014] The workpiece 10 on the right is called the leading workpiece, and the workpiece 101 is the slave workpiece. The main connecting piece 12, the cutting pad 41 and the workpiece 10 are integral parts bond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com