Pyrethroid compounds and application

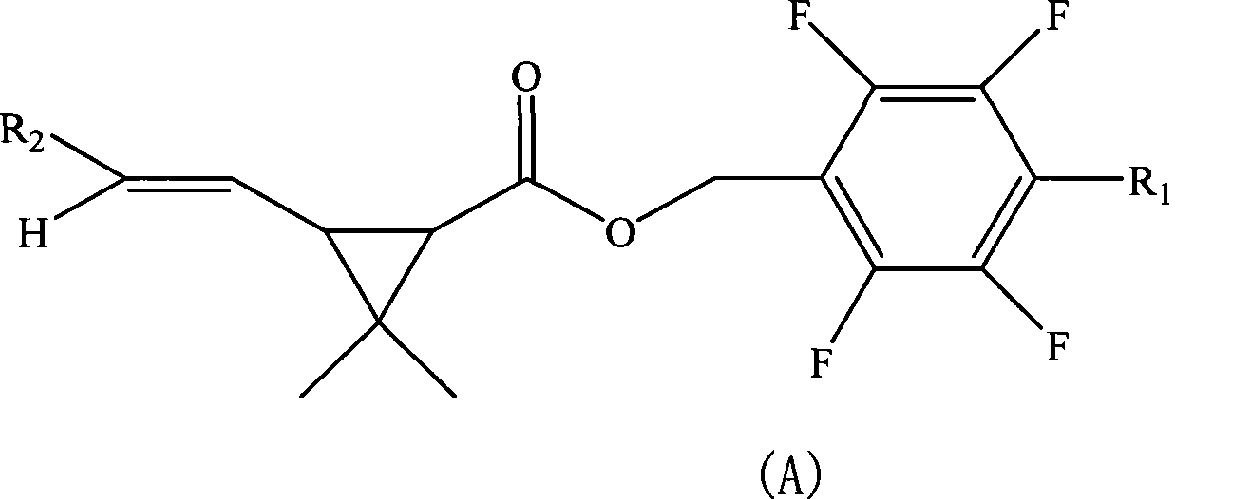

A technology for pyrethroids and compounds is applied in the field of pyrethroid compounds, which can solve the problems of increasing production costs, increasing environmental burden, increasing the amount of pyrethroids, and achieving the effect of quickly killing pests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

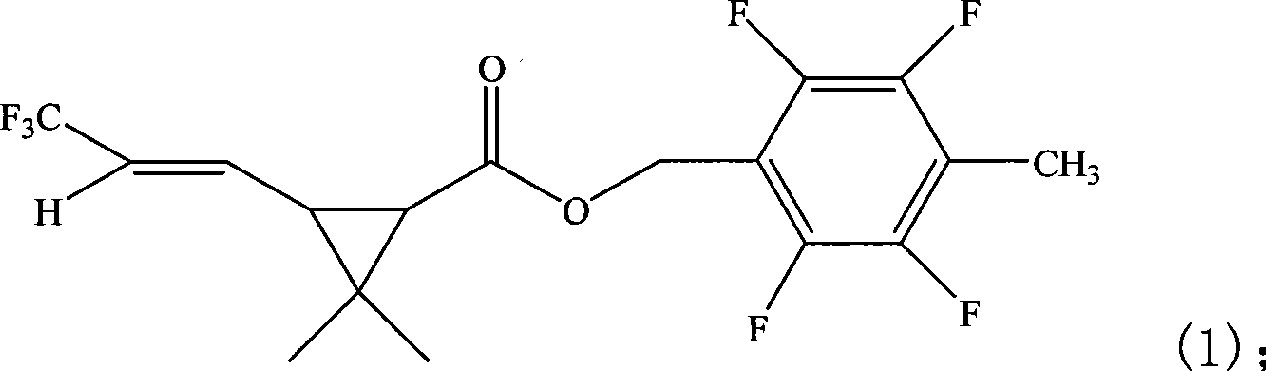

[0048] Preparation Example 1: 2,3,5,6-tetrafluoro-4-methylbenzyl-2,2-dimethyl-3-(3,3,3-trifluoro-propenyl)cyclopropanecarboxylic acid Synthesis of ester compound (1)

[0049] In a 2000ml four-necked bottle, put 97.0g (0.5mol) of 2,3,5,6-tetrafluoro-p-methylbenzyl alcohol, 50.0g of pyridine, dissolve in 800ml of toluene, stir after throwing in, 0-5°C 135.9 g (0.6 mol) of 2,2-dimethyl-3-(3,3,3-trifluoro-propenyl)cyclopropanecarboxylic acid chloride was added dropwise, and the temperature was raised to 20° C. for 4 hours after the dropwise reaction. Wash once with 400ml 5% hydrochloric acid, then wash with 400ml 5% NaHCO 3 After washing once, the oil layer was separated and heated to 100°C under a negative pressure of 10 mmHg to remove the solvent toluene to obtain the compound 2,3,5,6-tetrafluoro-4-methylbenzyl-2,2-dimethyl-3- (3,3,3-trifluoro-propenyl)cyclopropanecarboxylate, weight 188.7g, content 97.8%, yield 96.1%. The molecular formula of the compound: C 17 h 15 f 7 o...

preparation Embodiment 2

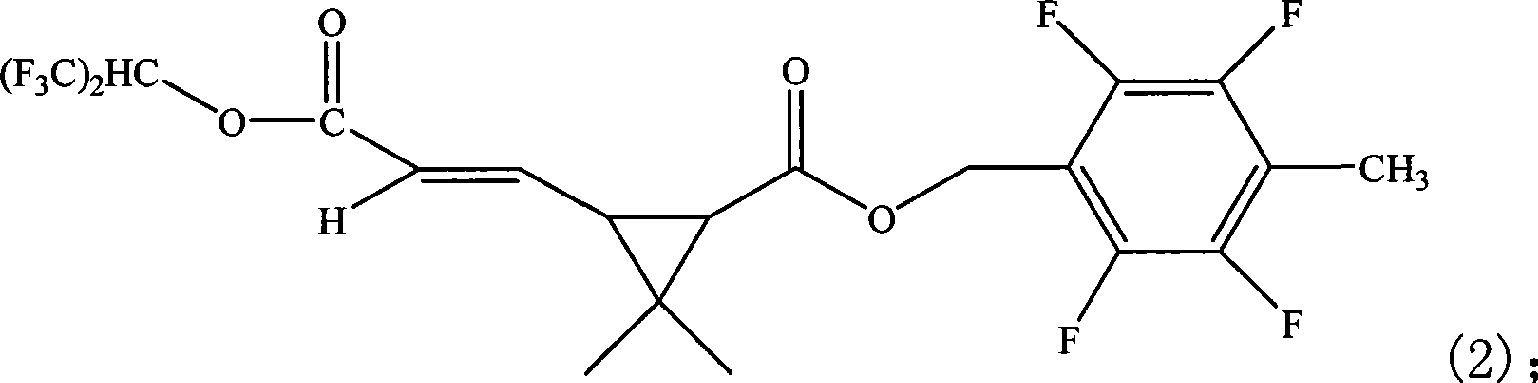

[0050] Preparation Example 2: 2,3,5,6-tetrafluoro-4-methylbenzyl-2,2-dimethyl-3-(2,2,2-trifluoro-1-trifluoromethylethyl Synthesis of Oxyformyl) Vinyl Cyclopropane Carboxylate Compound (2)

[0051] In a 2000ml four-necked bottle, put 97.0g (0.5mol) of 2,3,5,6-tetrafluoro-p-methylbenzyl alcohol, 50.0g of pyridine, dissolve in 800ml of toluene, stir after throwing in, 0-5°C Add dropwise 2,2-dimethyl-3-(2,2,2-trifluoro-1-trifluoromethylethoxyformyl)vinylcyclopropanecarboxylic acid chloride 211.5g (0.6mol), dropwise Bi rose to 20 ° C for 4 hours. Wash once with 400ml 5% hydrochloric acid, then wash with 400ml 5% NaHCO 3 After washing once, the oil layer was separated and heated to 100°C under a negative pressure of 10 mmHg to remove the solvent toluene to obtain the compound 2,3,5,6-tetrafluoro-4-methylbenzyl-2,2-dimethyl-3- (2,2,2-Trifluoro-1-trifluoromethylethoxyformyl)vinylcyclopropanecarboxylate, weight 250.3g, content 96.9%, yield 95.1%. The molecular formula of the compou...

preparation Embodiment 3

[0052] Preparation Example 3: 2,3,5,6-Tetrafluoro-4-methoxymethylbenzyl-2,2-dimethyl-3-(3,3,3-trifluoro-propenyl)cyclopropane Synthesis of Carboxylate Compound (3)

[0053] In a 2000ml four-necked bottle, put 112.0g (0.5mol) of 2,3,5,6-tetrafluoro-p-methoxymethylbenzyl alcohol, 50.0g of pyridine, dissolve in 800ml of toluene, stir after throwing in, 0- At 5°C, 135.9 g (0.6 mol) of 2,2-dimethyl-3-(3,3,3-trifluoro-propenyl)cyclopropanecarboxylic acid chloride was added dropwise, and the mixture was raised to 20°C for 4 hours after the dropwise reaction. Wash once with 400ml 5% hydrochloric acid, then wash with 400ml 5% NaHCO 3 After washing once, the oil layer was separated and heated to 100°C under a negative pressure of 10 mmHg to remove the solvent toluene to obtain the compound 2,3,5,6-tetrafluoro-4-methoxymethylbenzyl-2,2-dimethyl- 3-(3,3,3-trifluoro-propenyl)cyclopropanecarboxylate, weight 205.7g, content 97.5%, yield 96.9%. The molecular formula of the compound: C 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com