Application of roasted product of magnesia-alumina hydrotalcite in adsorption treatment of naphthol green B

A roasting product, adsorption treatment technology, applied in the preparation of organic compounds, nitro/nitroso dyes, organic chemistry, etc., can solve the problems of low treatment efficiency and secondary pollution of naphthol green B, and achieve fast adsorption rate , easy recycling, high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

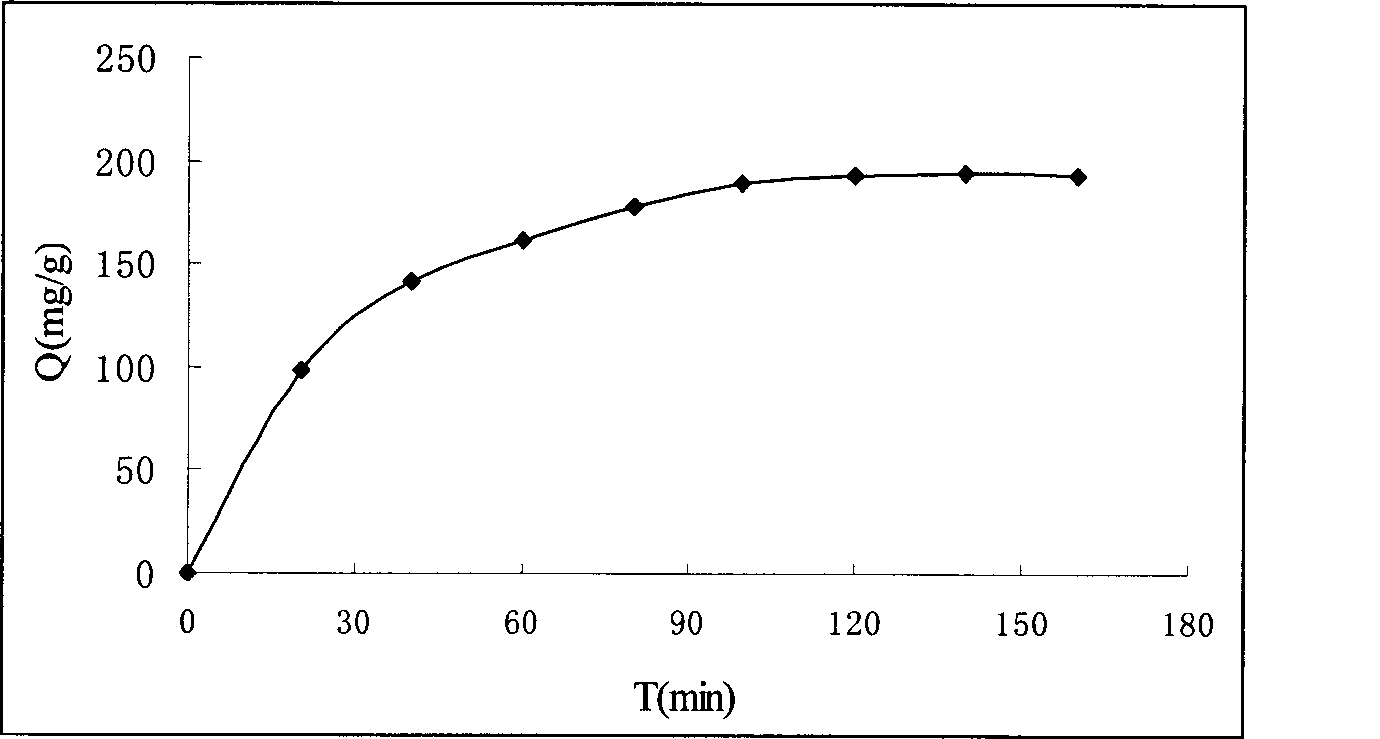

[0032]Prepare 8 parts of naphthol green B concentration and be the 100ml waste water of 200mg / L, take by weighing 8 parts of 100mg magnesium aluminum hydrotalcite roasting product, add respectively to be treated in the waste water that contains naphthol green B concentration and be 200mg / L, with 0.01mol / L NaOH and 0.01mol / L HCl control the pH to 10, the temperature is 45°C, and the stirring time is 20, 40, 60, 80, 100, 120, 140, and 160 min, respectively. After stirring, centrifuge, get the supernatant to measure the solution concentration after adsorption, the material changes with time to the adsorption amount of naphthol green B, see figure 1 .

[0033] Conclusion: In 100ml of naphthol green B wastewater solution with a concentration of 200mg / L, 100mg of magnesium aluminum hydrotalcite roasting product was added, and the adsorption equilibrium was reached after 100min at pH 10 and temperature 45°C.

Embodiment 9~13

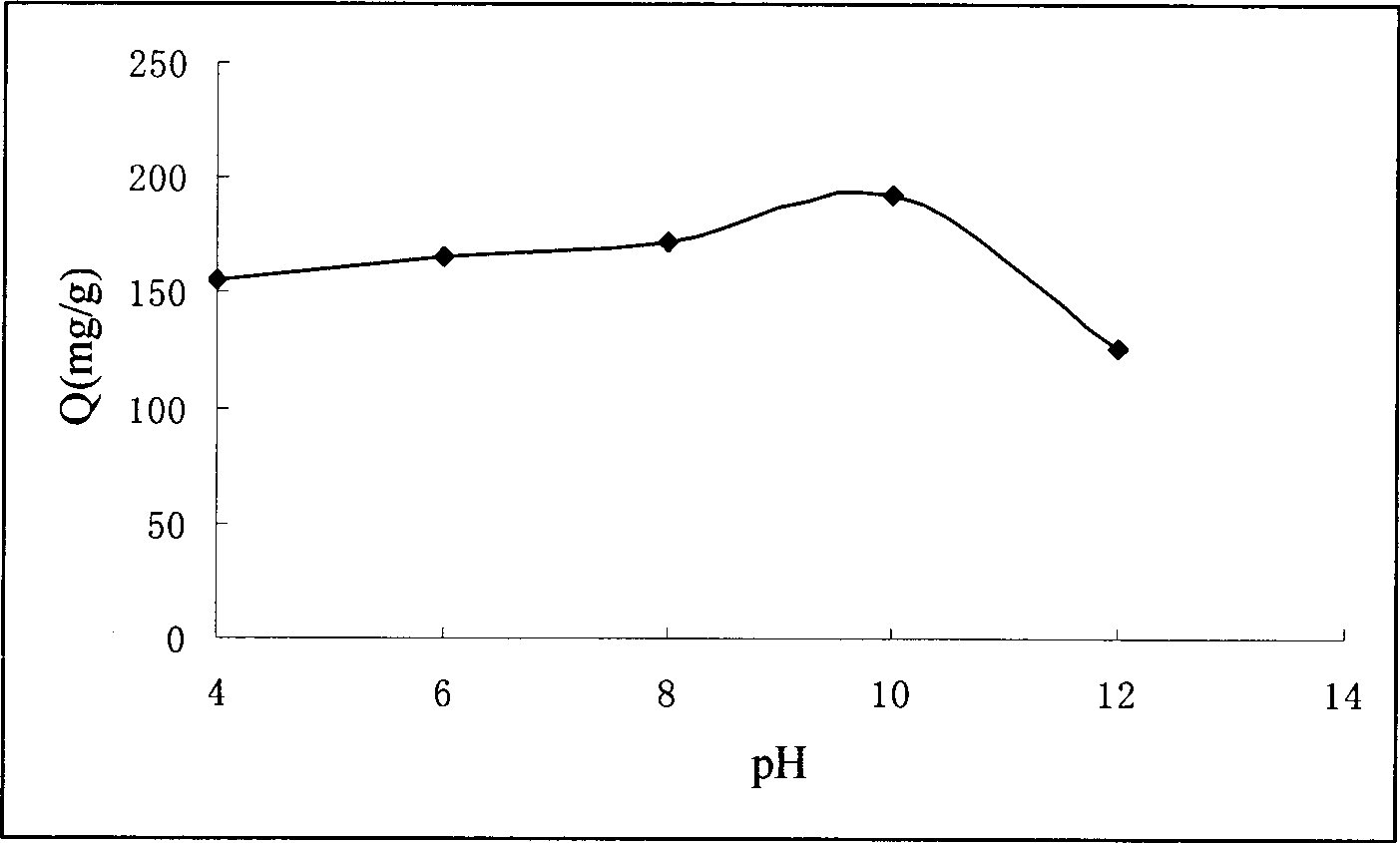

[0035] Prepare 5 parts of naphthol green B concentration and be the 100ml waste water of 200mg / L, take by weighing 5 parts of 100mg magnesium aluminum hydrotalcite roasting product, add respectively in the concentration to be treated in the naphthol green B waste water of 100mg / L, control temperature is At 45°C, adjust the pH to 4, 6, 8, 10, and 12 with 0.01mol / L NaOH and 0.01mol / L HCl, respectively, and stir for 120 minutes. After stirring, centrifuge, and take the supernatant to measure the adsorption solution concentration. The variation of the adsorption amount of naphthol green B by the material with pH is shown in figure 2 .

[0036] Conclusion: Add 100 mg of magnesium aluminum hydrotalcite roasting product to 100 ml of naphthol green B wastewater solution with a concentration of 200 mg / L, and the temperature is 45 ° C. Adsorption is performed under different pH conditions. When pH = 10, the adsorption capacity is the largest. It can reach 194mg / g.

Embodiment 14~19

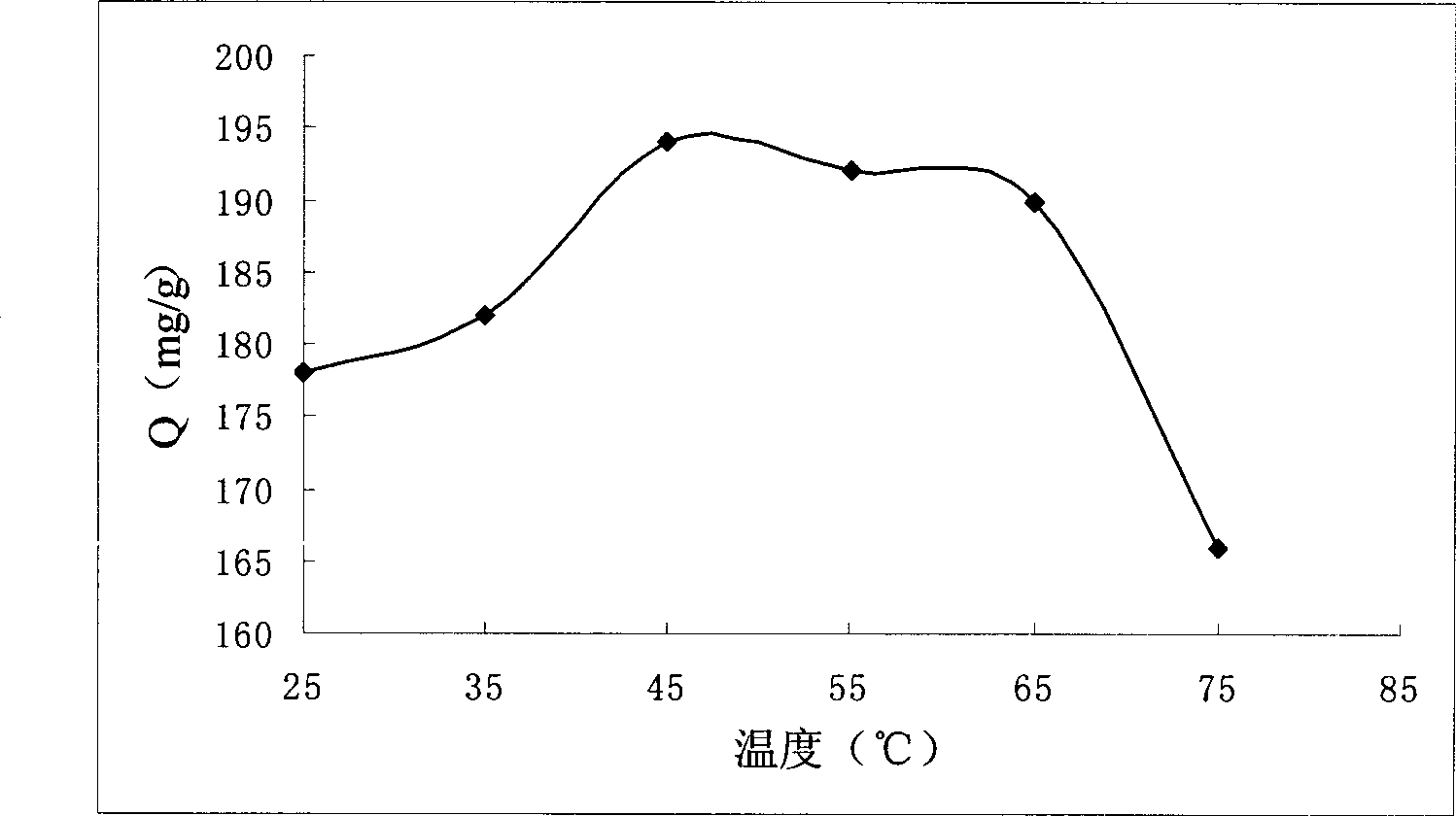

[0038] Prepare six parts of wastewater 100ml with a concentration of naphthol green B of 200mg / L, weigh six parts of 100mg magnesium aluminum hydrotalcite roasting products, and add them respectively to the wastewater of naphthol green B with a concentration of 100mg / L to be treated, with 0.01mol / L NaOH and 0.01mol / L HCl control the pH=10, and the temperature is 25, 35, 45, 55, 65, 75°C respectively. After stirring, the stirring time is 120min, centrifuged, and the supernatant is taken to measure the solution concentration after adsorption, and the adsorption amount of naphthol green B obtained by the material varies with temperature, see image 3 .

[0039] Conclusion: Add 100 mg of magnesium aluminum hydrotalcite roasting product to 100 ml of naphthol green B wastewater solution with a concentration of 200 mg / L, pH = 10, and adsorb at different temperatures. When the temperature is 45 ° C, the adsorption capacity is the largest, which can reach 194mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com