Wedge brake

A technology of brakes and brake hubs, applied in the direction of brake types, drum brakes, mechanical equipment, etc., can solve problems such as power increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

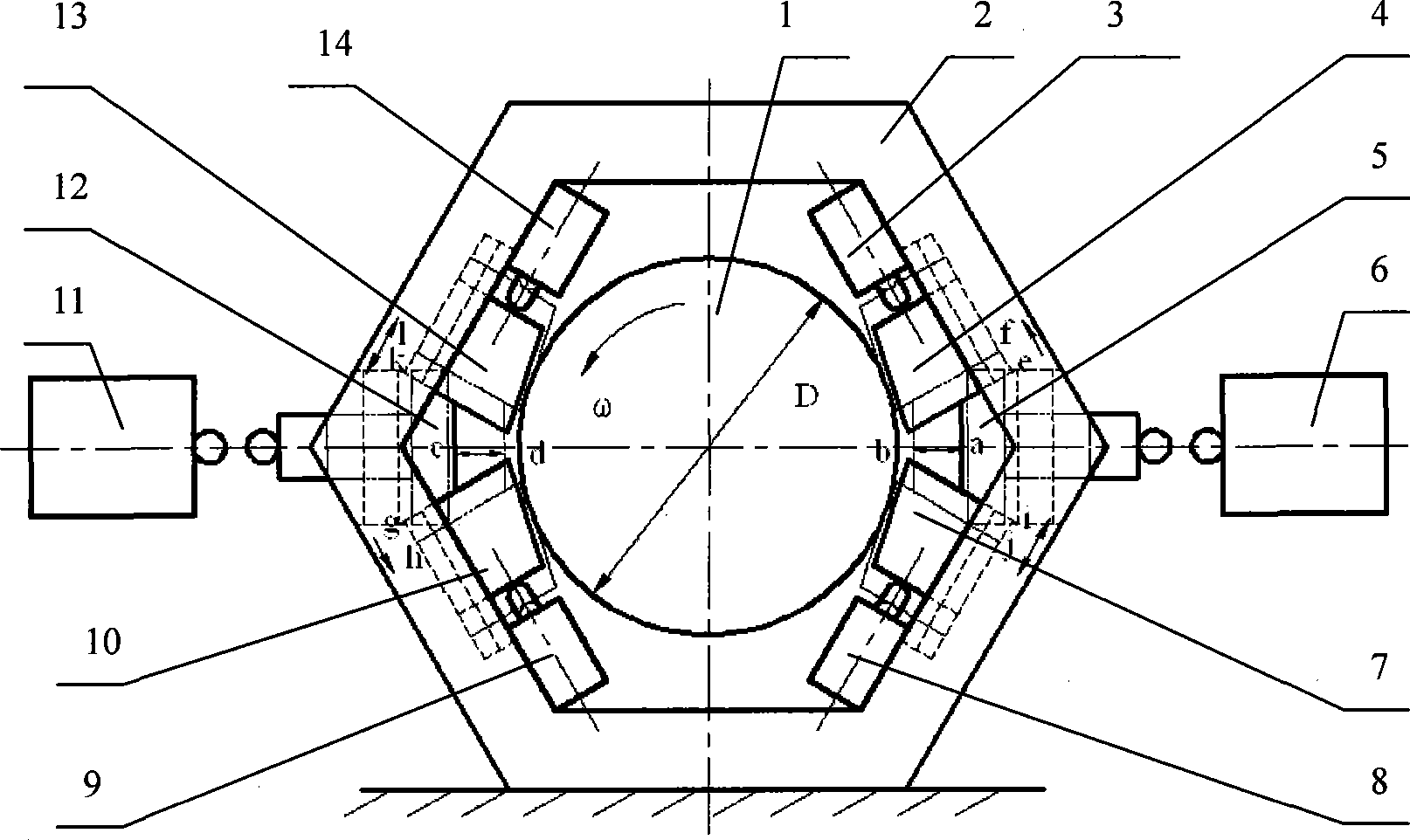

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0019] In conjunction with the accompanying drawings, the type wedge brake consists of a brake support body 2, four type wedges 4, 7, 10, 13, four damping energy storage devices 3, 8, 9, 14, two push rods 5, 12, two electromagnetic Valve 6,11, and brake hub 1 form. Four wedges and four damping energy storage devices are symmetrically arranged to achieve braking in two directions, and the brake hub shaft does not bear bending moment. Type wedges 4, 10, damping energy storage devices 3, 9, push rods 5, 12 and solenoid valves 6, 11 work together to realize braking in a counterclockwise direction; type wedges 7, 13, damping energy storage devices 8,14 Push rods 5,12 and electromagnetic valves 6,11 act together to realize that the braked steering is clockwise braking.

[0020] When braking is required (assuming that the steering direction is counterclockwise before b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com