Washing machine

A technology for washing machines and clothing, applied in the field of washing machines, can solve problems such as user confusion and confusion, and achieve the effects of easy operation, promotion of sealing, and noise suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

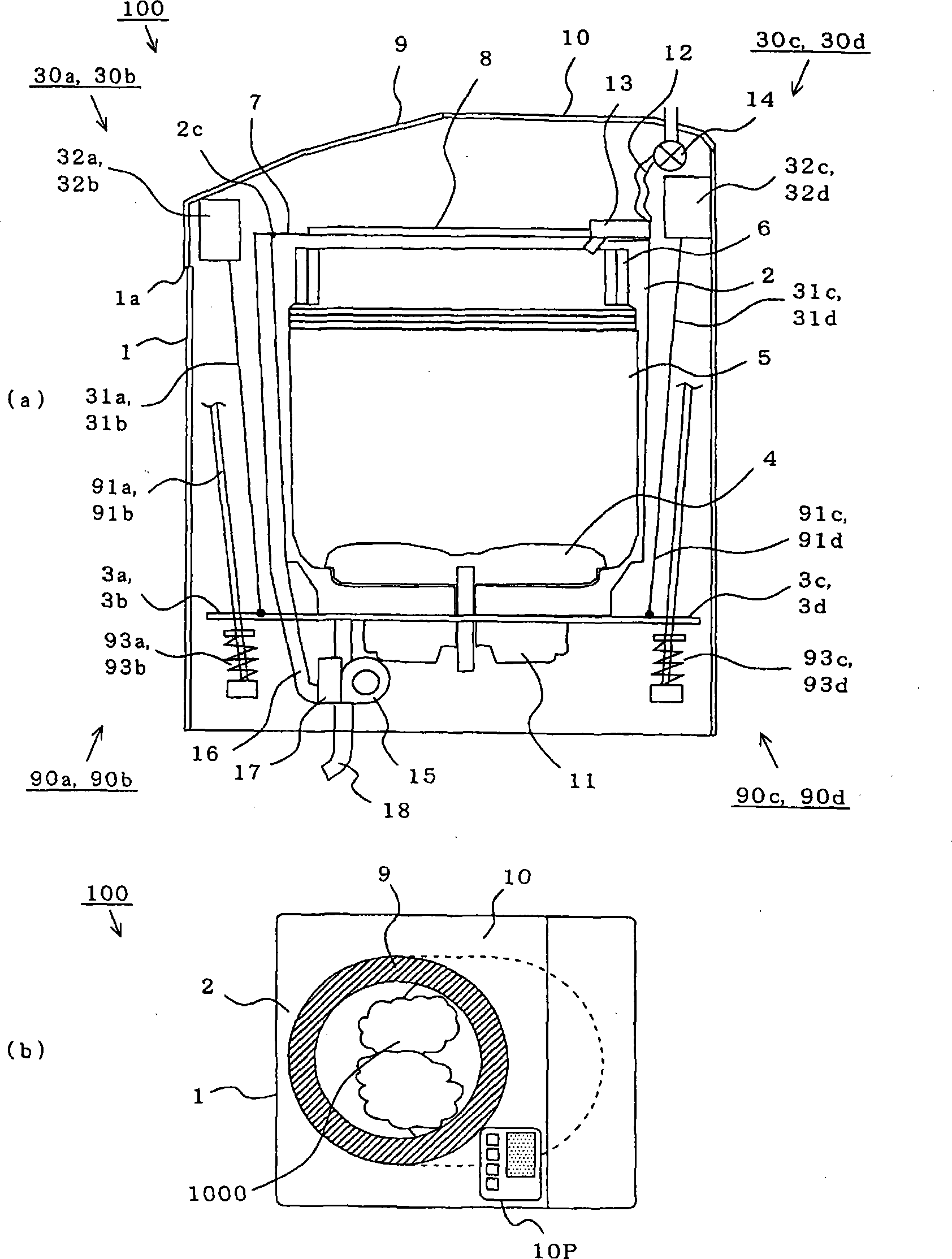

[0077] [Implementation 1; four hanging wires type]

[0078] figure 1 It is a figure explaining the washing machine concerning Embodiment 1 of this invention, (a) is a side sectional view, (b) is a top view. In addition, since each component is shown schematically in the figure, the size, the interval of each part, etc. are not correct. Especially for components formed from thin plates, the thicknesses are shown exaggerated for clarity. In addition, in the following description, description of the footnotes "a, b, c, d" is omitted for common content, and in each figure, the same part or corresponding part is attached|subjected to the same code|symbol, and part description is abbreviate|omitted.

[0079] (washing machine)

[0080] exist figure 1 In (a), the washing machine 100 is a washing machine that performs a series of main washing steps, rinsing steps, dehydration steps, and drying steps. state), the main washing process and the drying process are mainly performed, and...

Embodiment approach 2

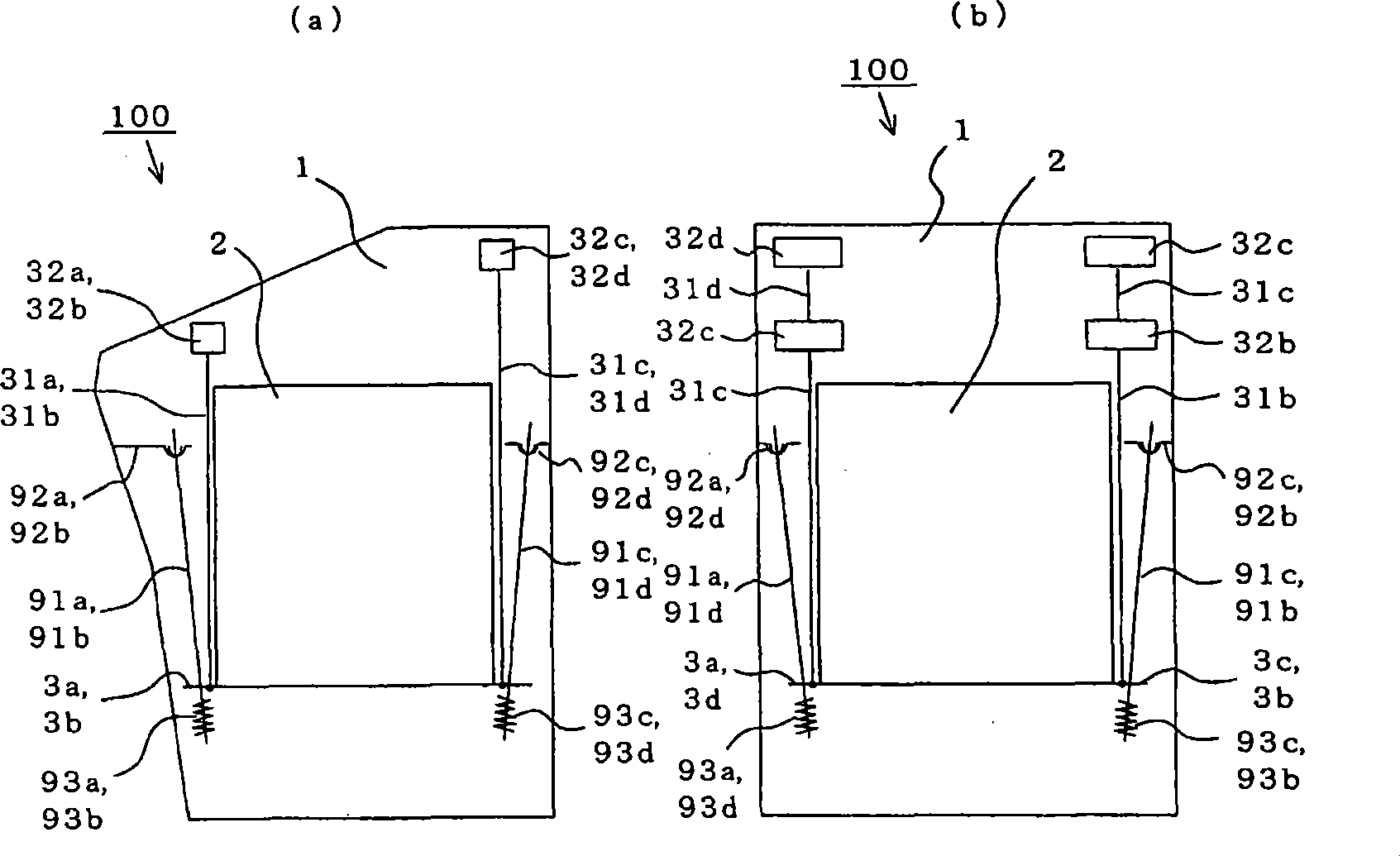

[0131] [Embodiment 2; two hanging wires type]

[0132] Figure 4 as well as Figure 5 It is a figure explaining the inclination of the washing tub in the washing machine according to Embodiment 2 of the present invention, and it shows schematically through the surface of the casing of the washing machine, Figure 4 (a) is a side view of the dehydration process, Figure 4 (b) is a rear view of the dehydration process, Figure 5 (a) is a side view of the washing process, Figure 5 (b) is a back view of a washing process.

[0133] exist Figure 4 , 5 Among them, the washing machine 200 is different from the washing machine 100 (Embodiment 1) in that the water tank 2 is suspended by the suspension mechanisms 40a, 40b provided on the front side and the suspension mechanisms 50c, 50d provided on the rear side. The washing machine 100 is the same. Next, different points will be described.

[0134] (hanging mechanism)

[0135] exist image 3 , 4 Among them, the suspension ...

Embodiment approach 3

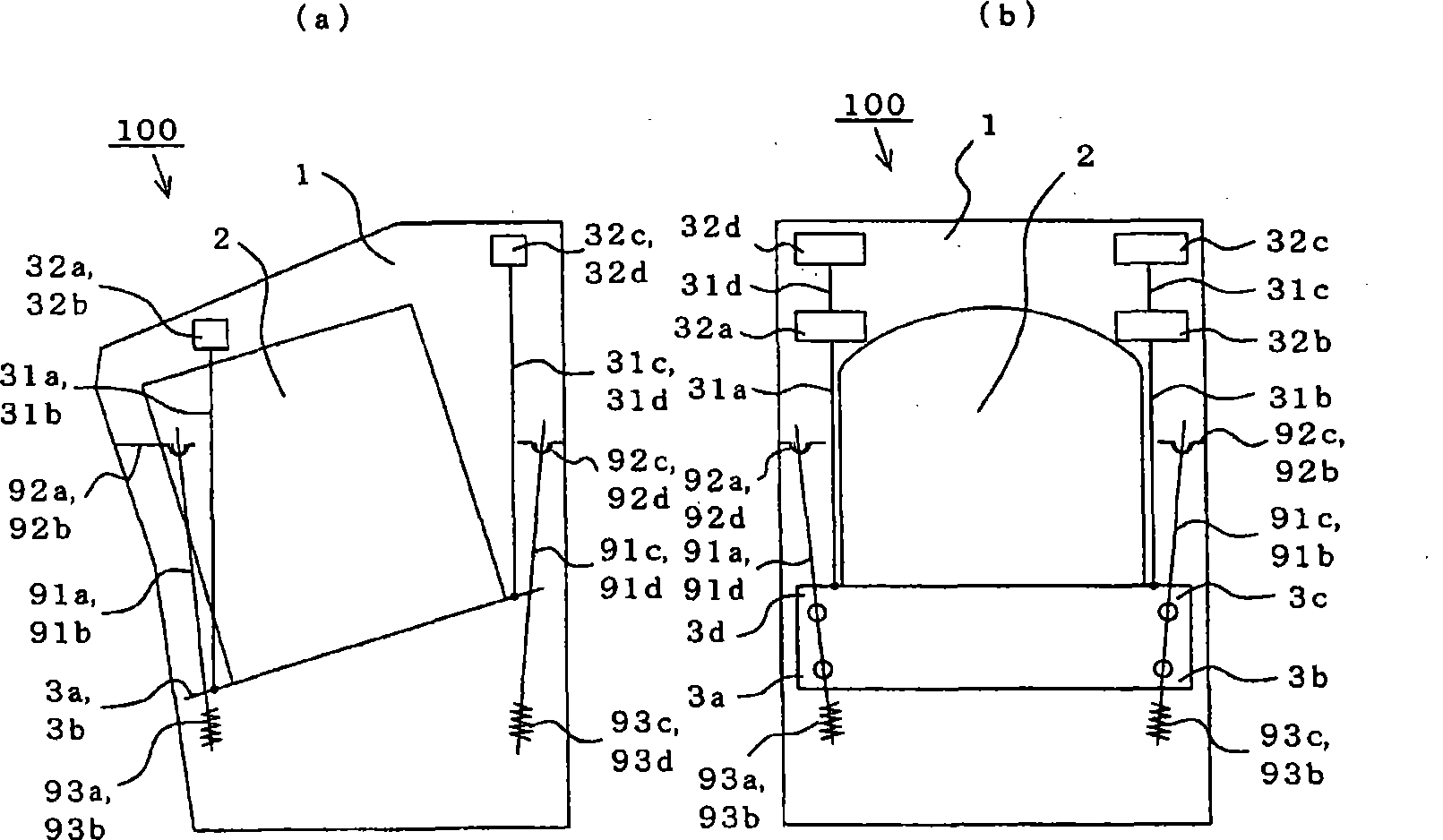

[0149] [Embodiment 3; 1 hanging metal wire type]

[0150] Image 6 as well as Figure 7 It is a figure explaining the inclination of the washing tub in the washing machine according to Embodiment 3 of the present invention, and it shows schematically through the surface of the casing of the washing machine, Image 6 (a) is a side view of the dehydration process, Image 6 (b) is a rear view of the dehydration process, Figure 7 (a) is a side view of the washing process, Figure 7 (b) is a back view of a washing process.

[0151] exist Image 6 , 7 Among them, the washing machine 300 is different from the washing machine 100 (Embodiment 1) in that the water tank 2 is suspended by the suspension mechanisms 40a, 40b provided on the front side and the suspension mechanism 30e provided on the rear side, and it is different from the washing machine 100 in other respects. same. The differences will be described below.

[0152] (hanging mechanism)

[0153] exist Image 6 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com