Processing method of conical tube internal thread of large diameter

A processing method and internal thread technology, which is applied in the processing field of large-diameter tapered pipe internal threads, can solve the problems of large-diameter tapered pipe internal thread processing difficulty and high production cost, so as to reduce processing and manufacturing costs, meet precision and use requirements, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

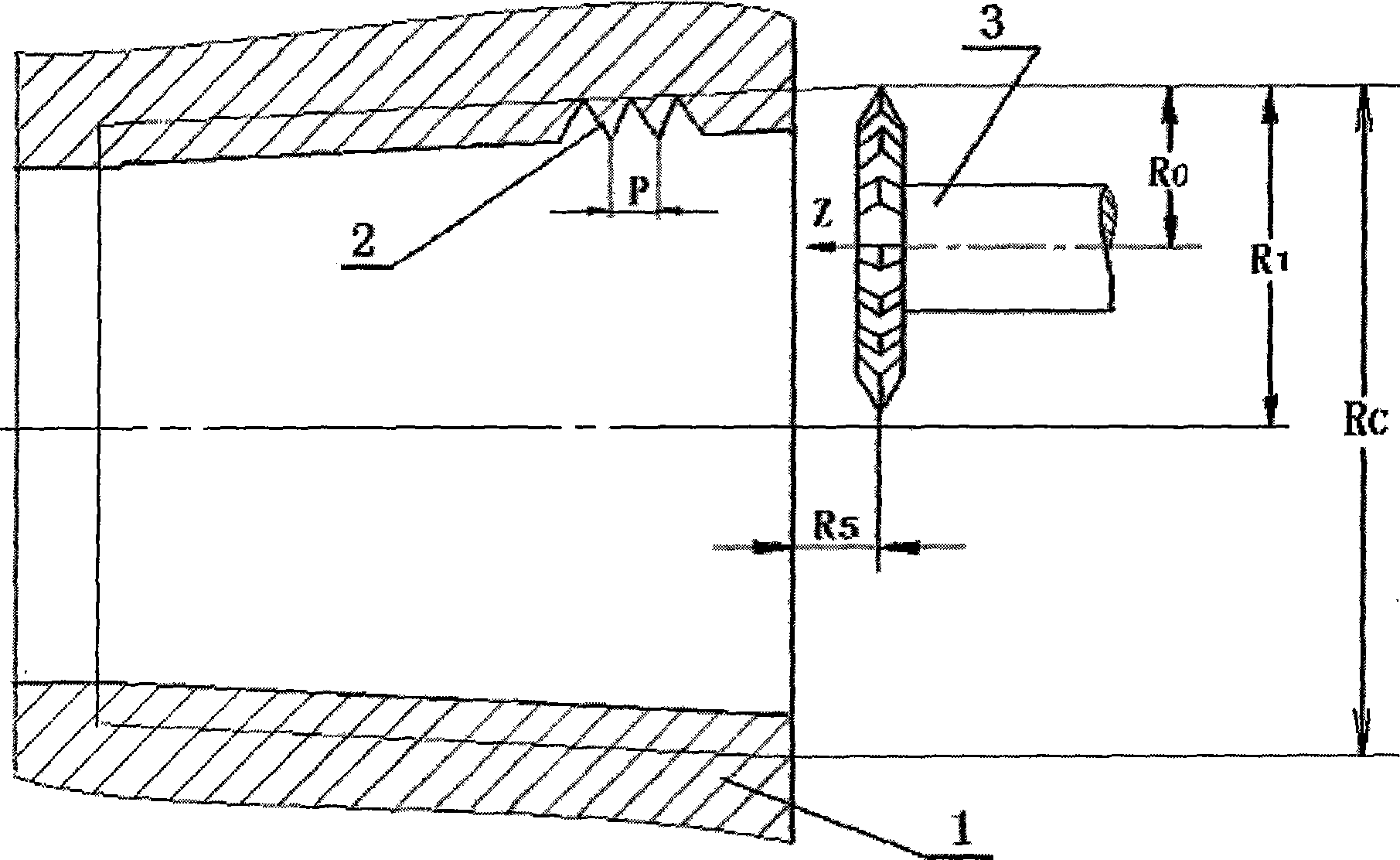

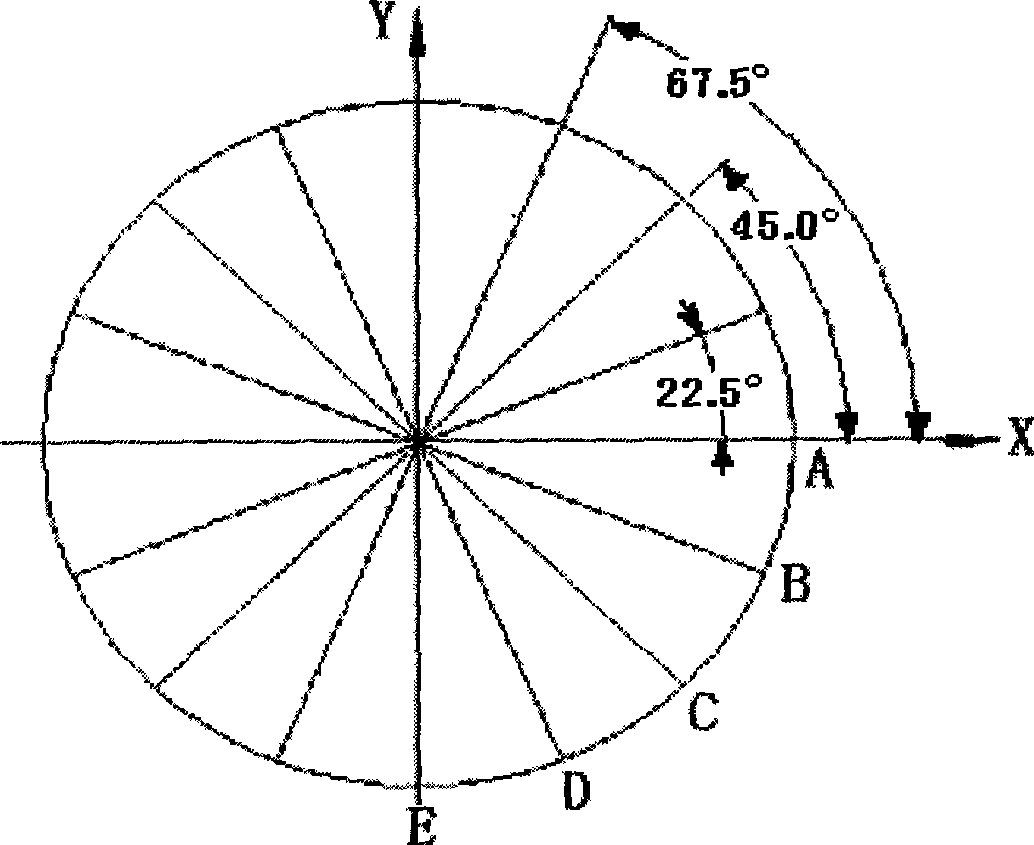

[0016] Such as figure 2 As shown, the processing of the tapered pipe internal thread of the inventive method adopts the method that several sections of cylindrical thread lines with different diameters are connected end to end, and the projection of a pitch thread along the axial direction is approximately a full circle, which is divided into several equal parts, as For the convenience of calculation and programming, the whole circle is divided into 16 equal parts, and each equal part is 22.5°. Within the angle range of each equal part, the internal thread is processed as a cylindrical thread, that is, the Z axis moves P / 16 (P is the pitch), The X and Y axes walk a 1 / 16 arc, and at the end of each arc, the coordinates of X and Y gradually decrease by the set value according to the slope value of the internal thread, and move to the starting point of the next arc for processing. A section of circular arc, after the X and Y axes walk a full circle, the Z axis just walks a pitch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com