Anode refining method for high sulphur raw copper

A blister copper, high-sulfur technology, applied in the field of copper metallurgy, can solve the problems of harsh operating environment, reduced copper smelting efficiency, consumption of natural gas, etc., to improve production efficiency and production capacity, solve the problem of black smoke pollution, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

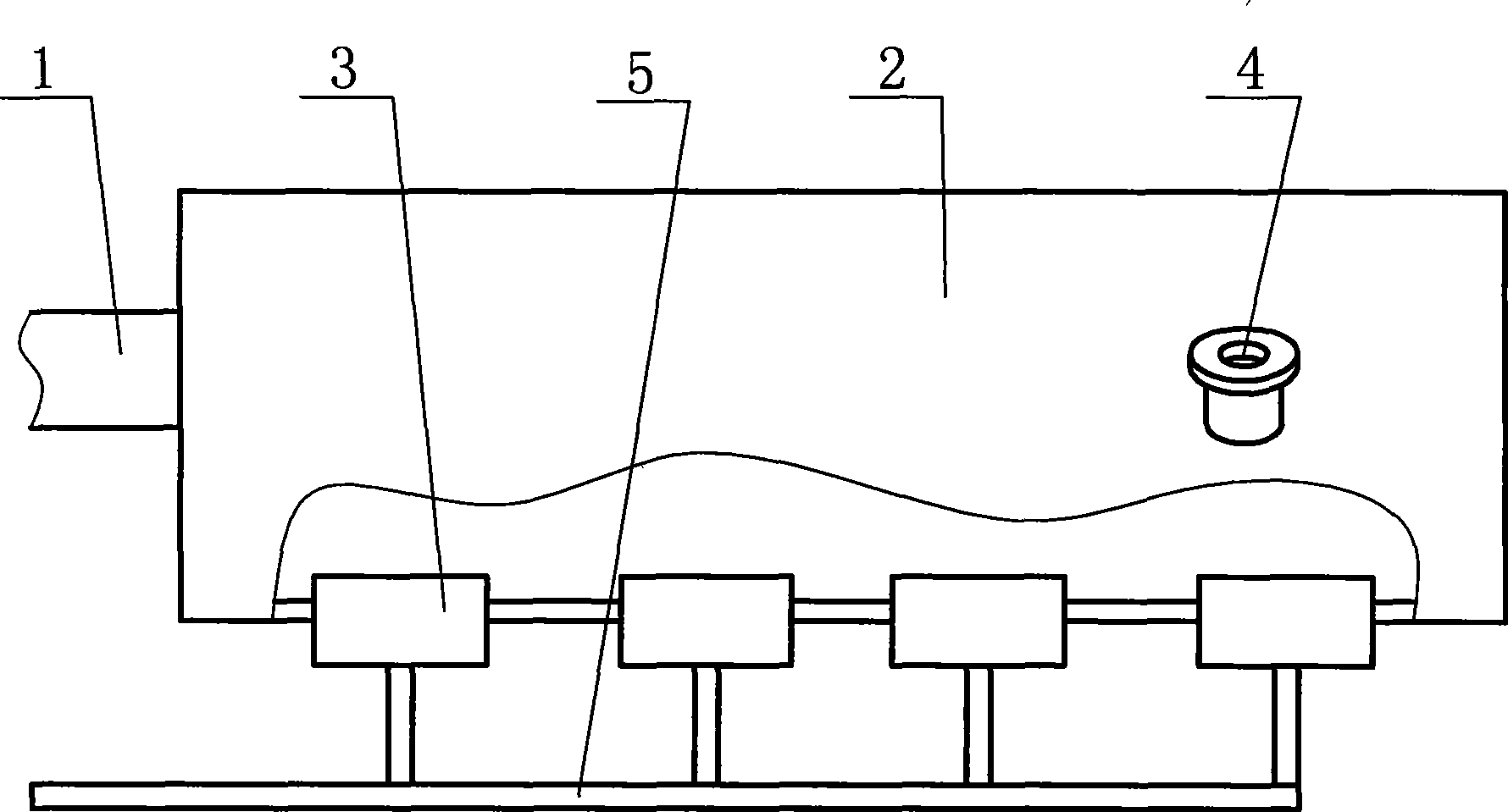

[0019] refer to figure 1 Specifically explain the process: first, the blister copper liquid produced by the flash converting furnace is injected into the anode furnace 2 through the chute 1 at a speed of 50 to 100 tons / hour. Ventilation device 3 blows inert gas into the furnace continuously, the flow rate of inert gas is 50-2000Nm 3 / h (determined according to the size of the anode furnace), pressure 0.4-0.8MPa, temperature 25°C-300°C, inert gas makes the blister copper liquid in the anode furnace 2 continuously boil, and promotes the sulfur in the blister copper liquid and the oxygen in the blister copper liquid And the oxygen absorbed from the surface of the copper liquid is fully exposed to the reaction, and the generated SO 2 The gas is discharged from the copper liquid to achieve the purpose of sulfur removal. After the feeding is finished, shallow (none) oxidation and shallow (none) reduction operations are respectively adopted according to the sulfur content of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com