Revetment T shaped pile with tongue and groove

A tongue-and-groove and tongue-and-groove technology, applied in the field of revetment T-shaped piles, can solve the problems of large gaps between piles, poor water and soil sealing effect, etc., to improve bending resistance, water and soil sealing effect, stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

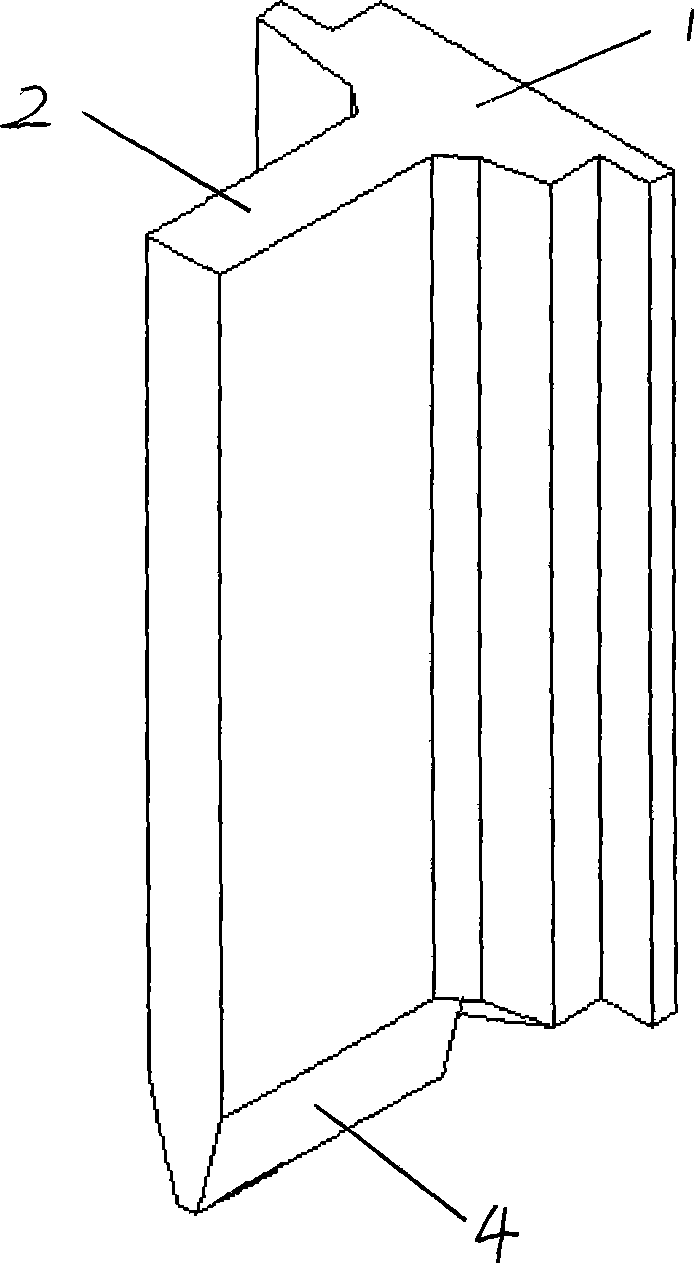

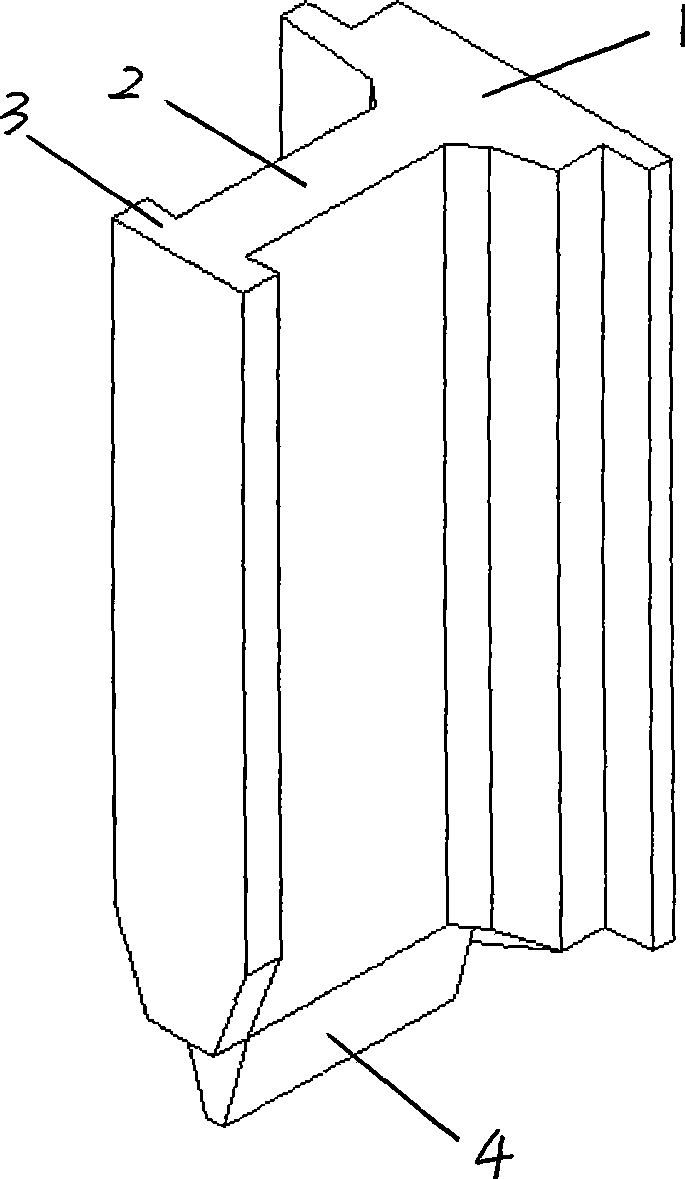

[0027] Such as figure 1 , figure 2 As shown, the pile is T-shaped by the first panel 1 and the web 2, and there is a gradual transition between the panel and the rib, and there are two types of bevel transition and arc transition at the corner transition, and in the first panel 1 The wings have tongue and groove. figure 2 The shape of the T-shaped pile shown is also similar to the shape of "I", and the other end of the web 2 is connected to the second panel 3 . The lower ends of the first panel 1 and the web 2 are respectively formed with oblique cutting edges 4 with the same inclination direction, which can generate passive earth pressure to squeeze adjacent piles together during piling.

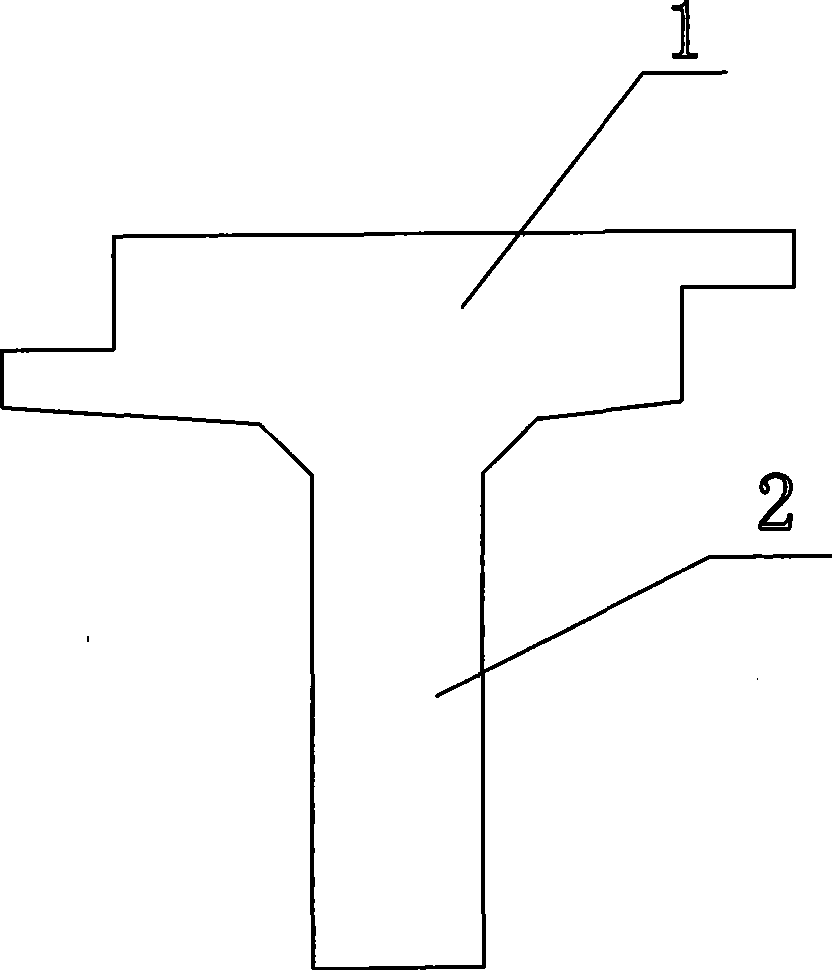

[0028] image 3 , Figure 4 It is a "T"-shaped pile, and the two ends of the panel are flat tenon and tongue-and-groove, and the slight difference is image 3 The corner transitions of are beveled, Figure 4 The corners of are arcs.

[0029] Figure 5 , Figure 6 The "T"-shaped p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com