Copper foil spot-welder

A spot welding machine and copper foil technology, applied in welding equipment, resistance welding equipment, coil manufacturing, etc., can solve the problems of large manpower consumption, increased product cost, and long time, so as to save finished products, avoid environmental pollution, and save labor and the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, specific embodiment is described:

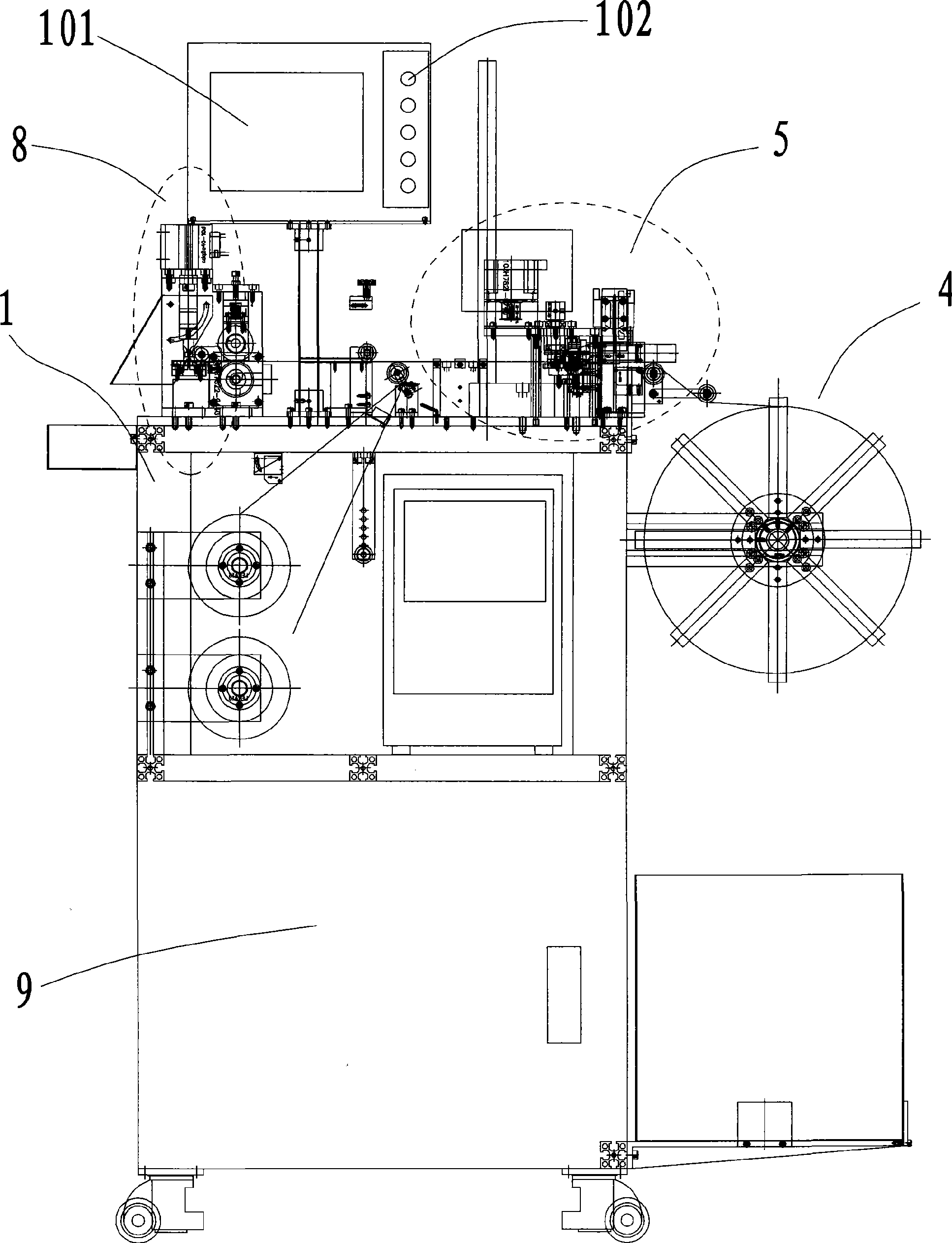

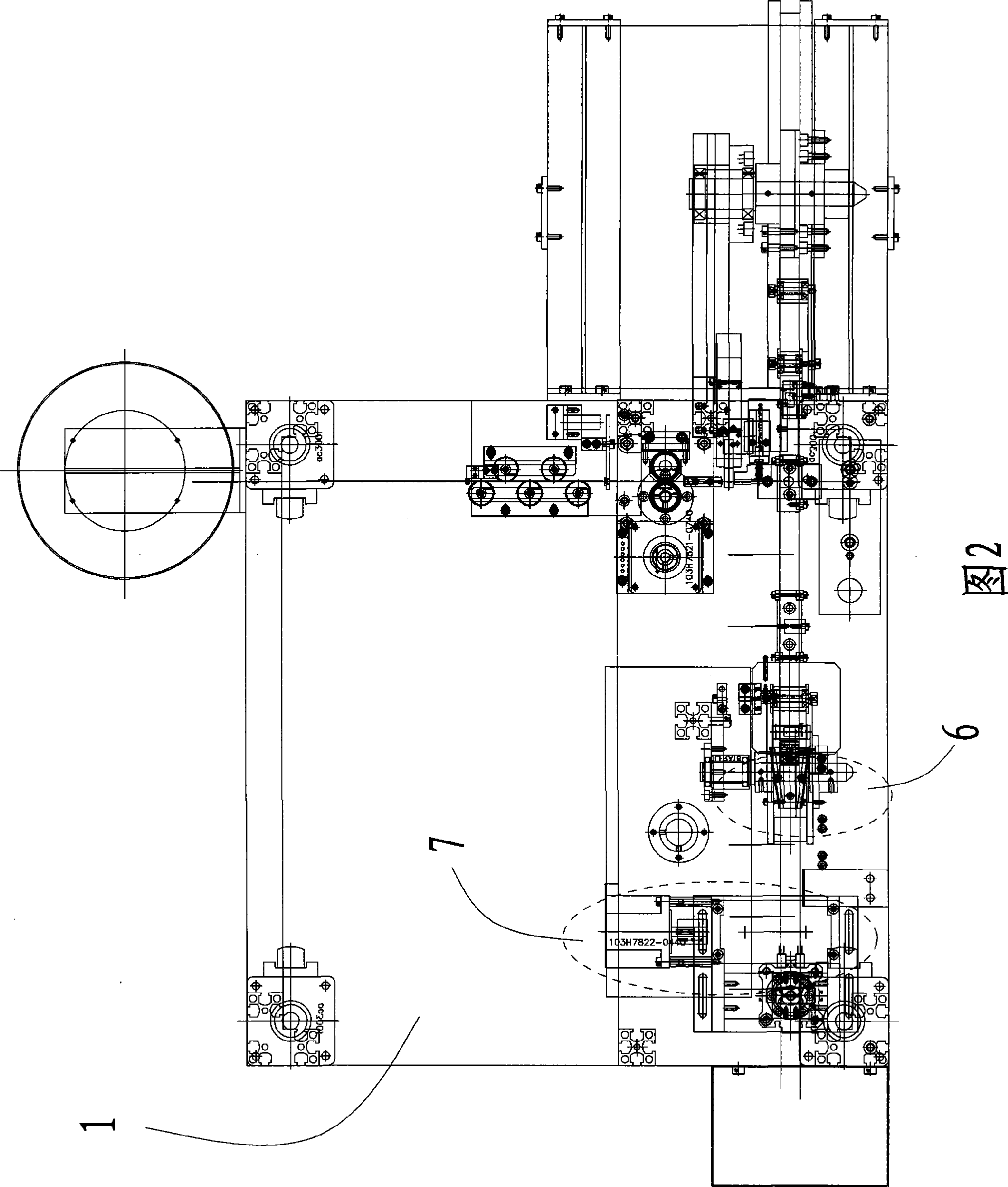

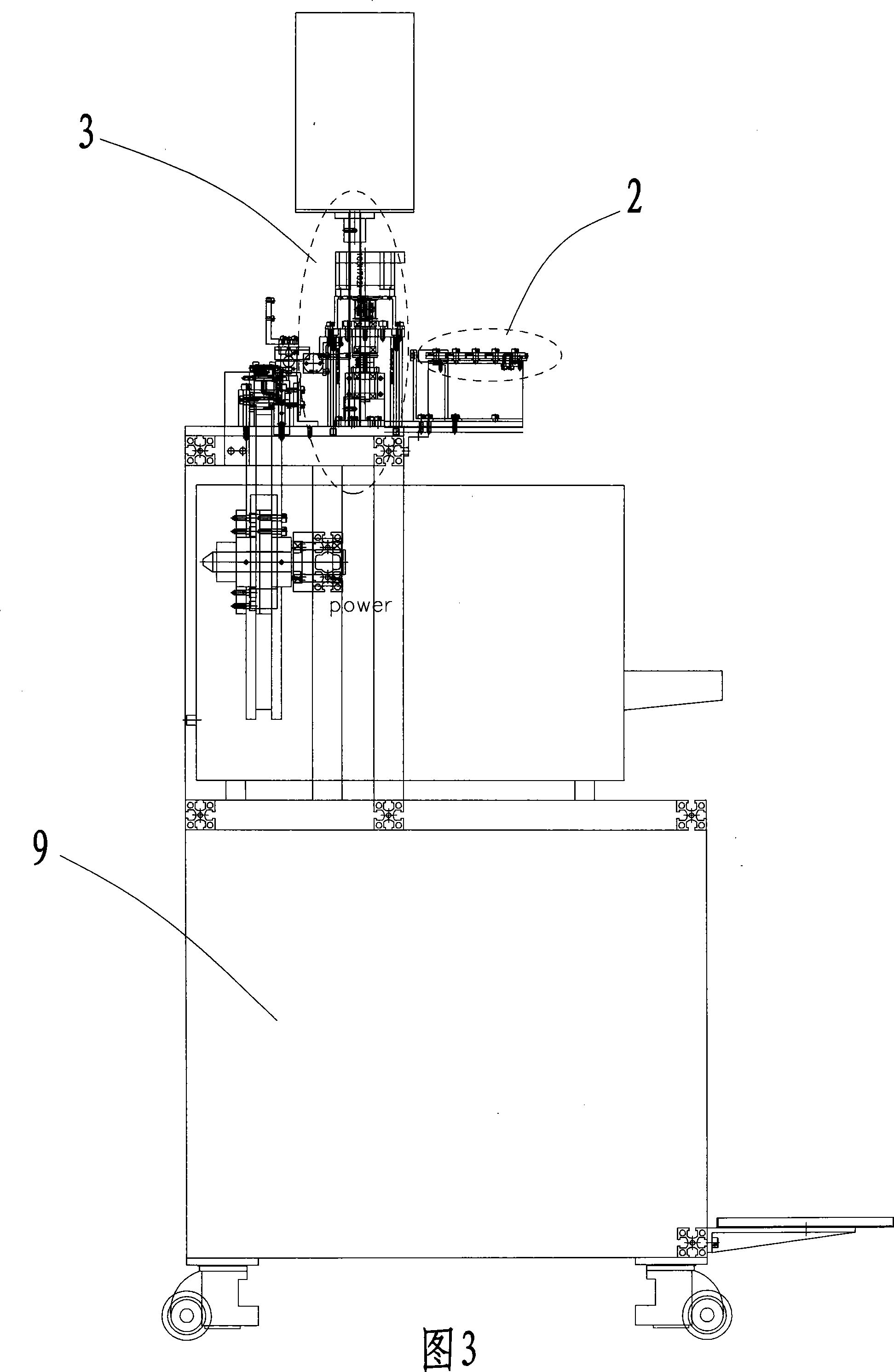

[0021] like figure 1 , shown in Fig. 2 and Fig. 3, a kind of copper foil spot welding machine is characterized in that: comprises

[0022] A frame 1: a carrier for carrying subsequent components;

[0023] A wire management mechanism 2: installed on the upper right side of the frame, used to straighten the coiled enameled wires and send them to the follow-up mechanism;

[0024] A wire feeding mechanism 3: installed on the upper part of the frame, used to send the enameled wire sent by the wire management mechanism to the follow-up mechanism, and can accurately control the length of the enameled wire sent to the follow-up mechanism;

[0025] A copper foil installation mechanism 4: installed in the middle and lower part of the frame, for positioning the copper foil;

[0026] A welding mechanism 5: installed in the middle of the frame, used to weld together the enameled wire fed by the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com