Charge air cooler arrangement with cooler bypass and method

A configuration structure, intercooler technology, applied in the direction of machines/engines, adding non-fuel substances to fuel, charging systems, etc., can solve problems such as condensation that has not been completely solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

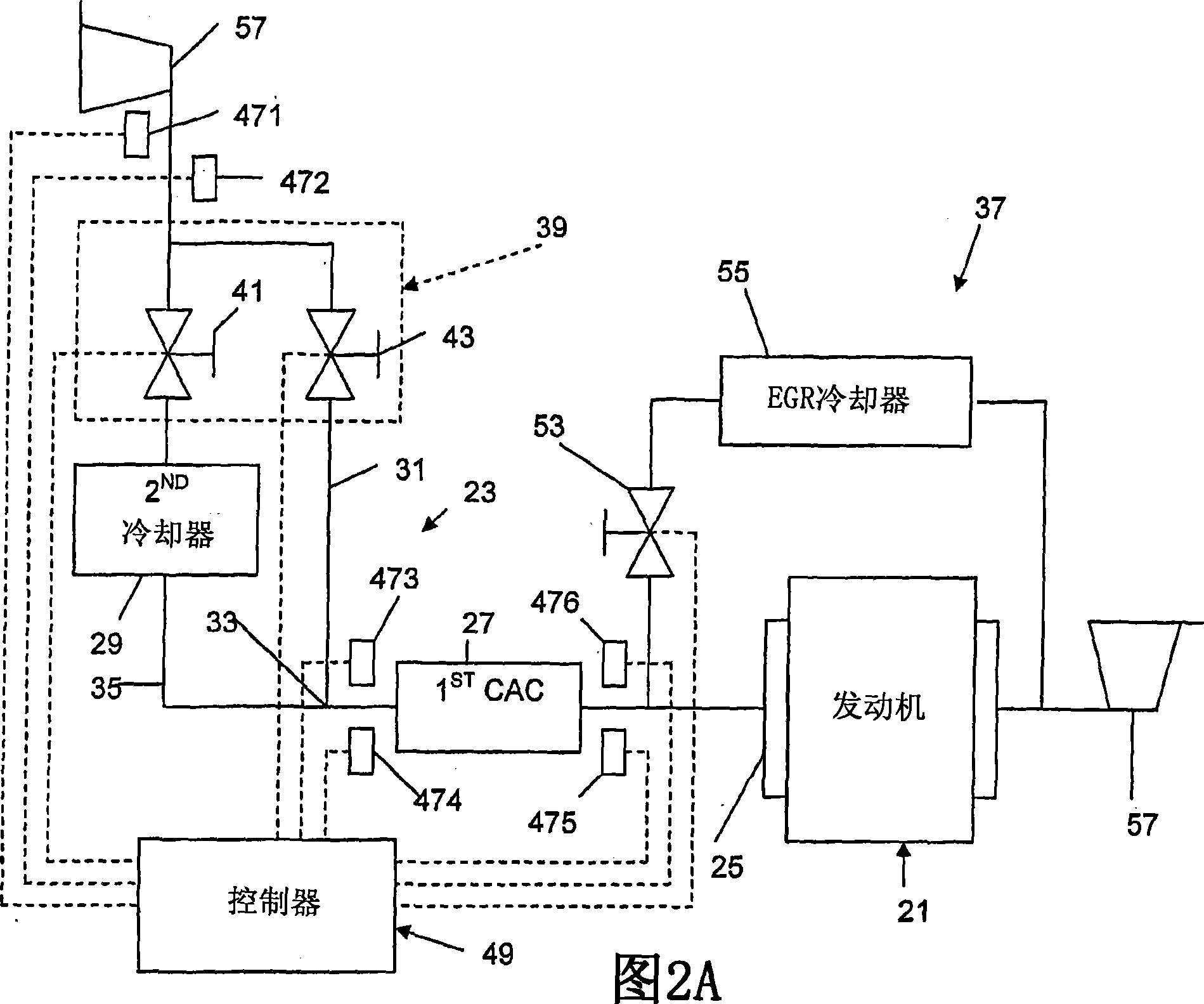

[0014] An engine 21 with an intercooler arrangement 23 is shown in FIG. 2A . An intake port, typically an intake manifold 25 , leads to the engine 21 . A first intercooler 27 (CAC) is provided upstream of the intake manifold 25 . The first CAC 27 may be less efficient than a CAC typically used in conventional internal combustion engines. More particularly, it is desirable for air located in or downstream of the first CAC that the first CAC 27 is not sufficiently effective to cool the air below the dew point within the range of temperatures and relative humidity at which it is desired to operate the engine 21 . In other words, the first CAC 27 will generally not be able to cause condensation downstream of the first CAC.

[0015] The second cooler 29 is provided upstream of the first CAC 27 . The second cooler 29 and the first CAC 27, desirably operating in series, are capable of reducing the intake air temperature over the range of temperatures and relative humidity at which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com