Lubricating oil heating method of frequency converting air-conditioner compressor

A heating method and frequency conversion air conditioner technology, which is applied to liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problems of inability to start, large starting load of the compressor, damage to the compressor, etc., to save costs, Guarantee the effect of normal startup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

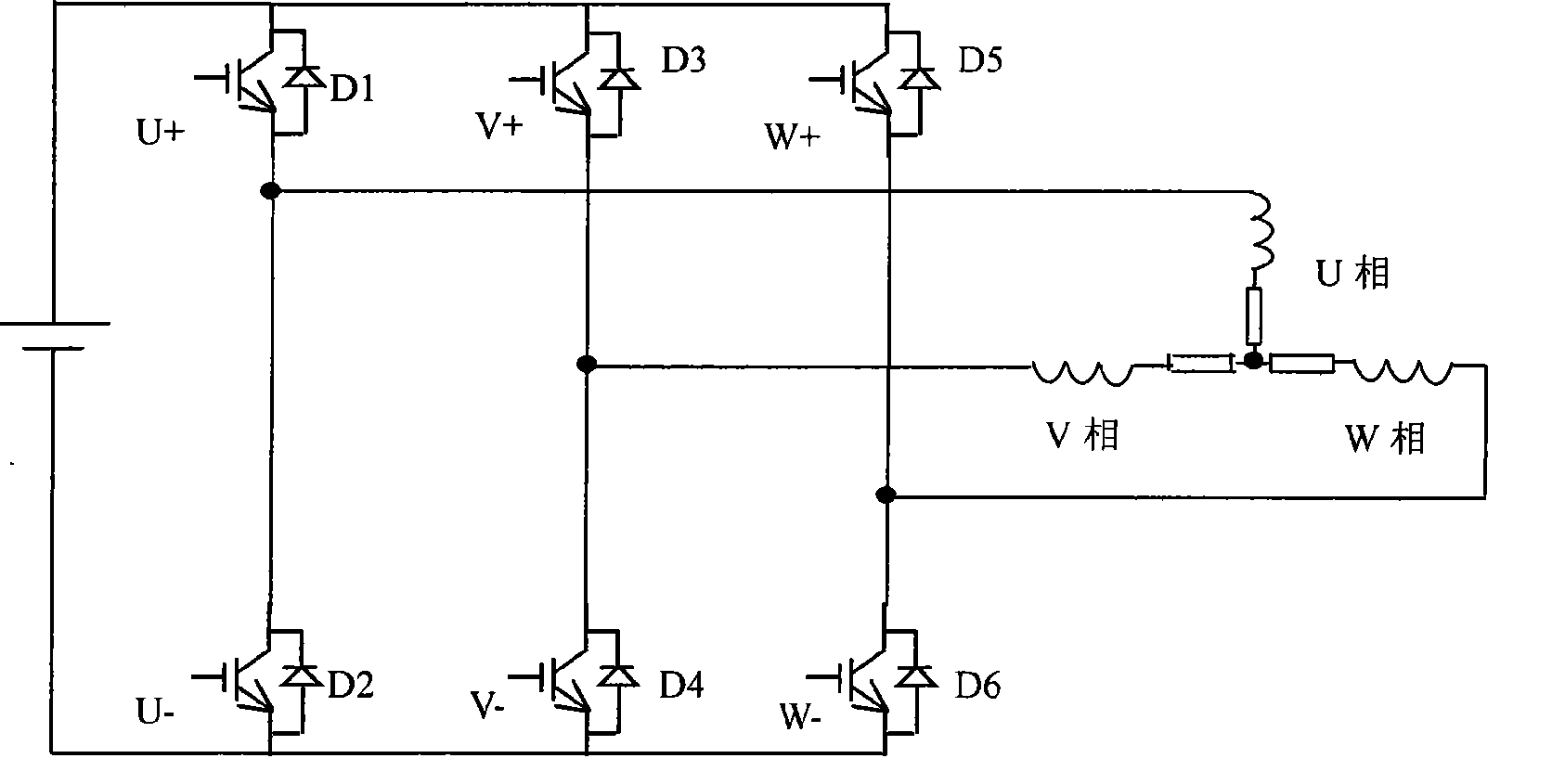

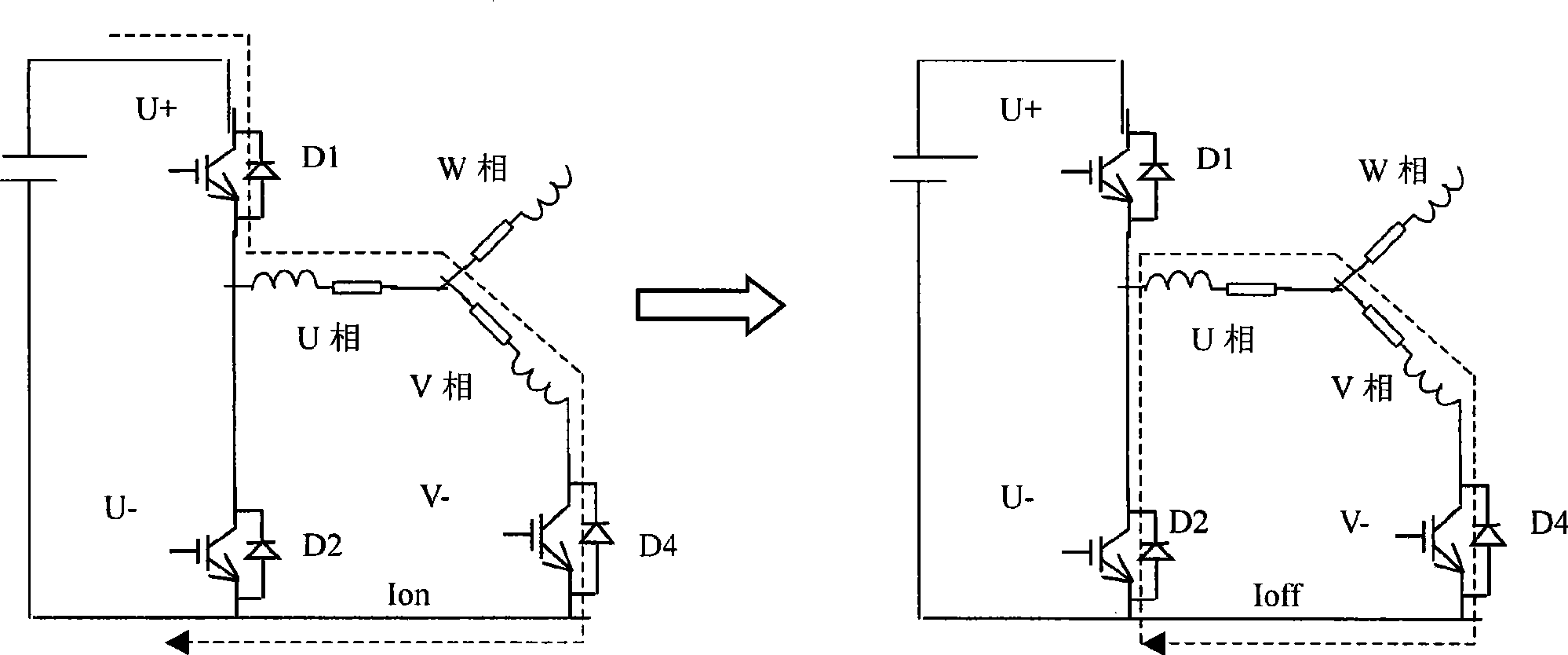

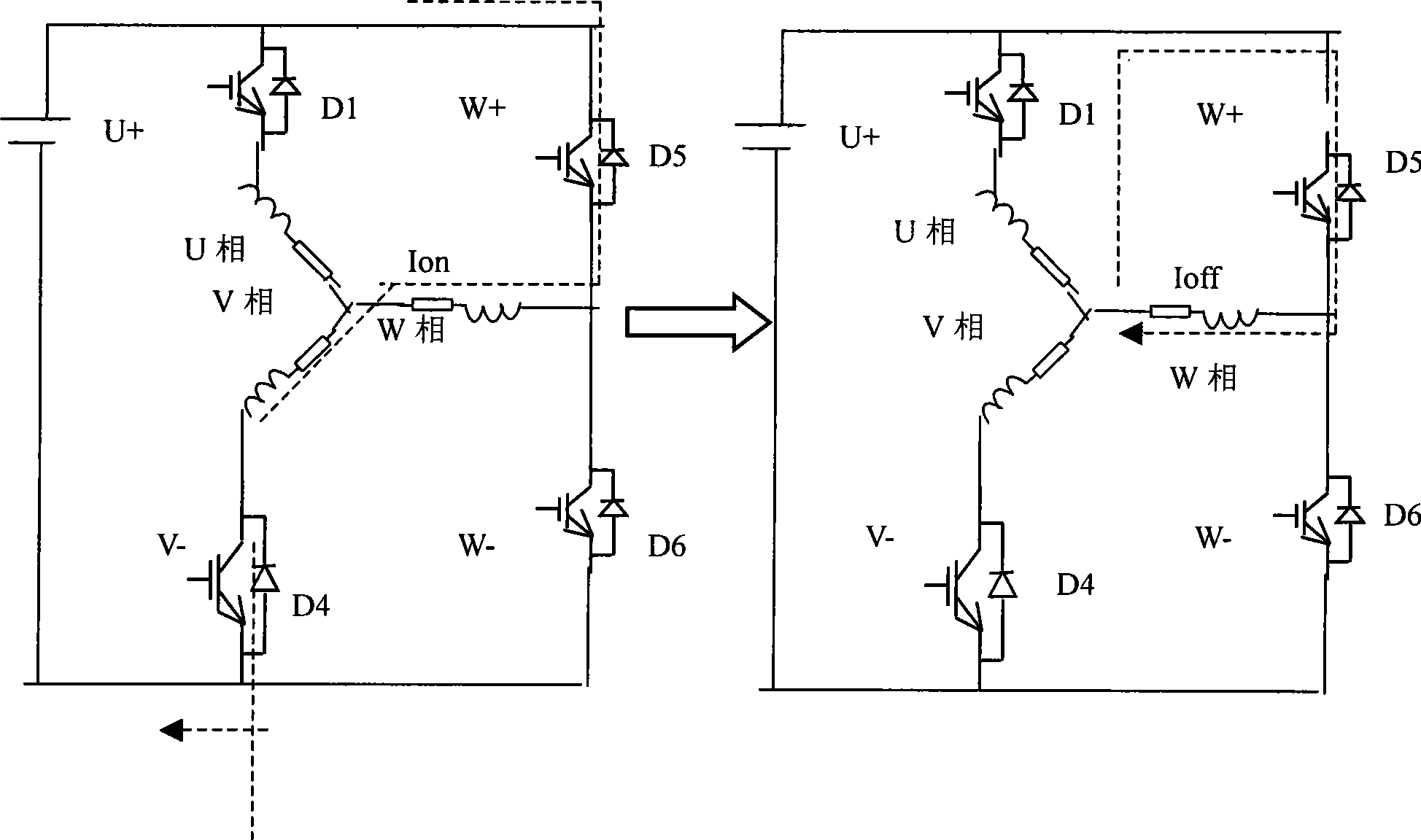

[0015] The heating device of the present invention borrows the six-way IGBT and the relevant peripheral circuits of the single-chip microcomputer to drive the frequency conversion compressor, and its connection mode is explained (see figure 1 ). The six IGBTs U+, U-, V+, V-, W+, and W- are respectively connected to the PWM output port of the microcontroller. Every two IGBTs named after U, V, and W are connected in series respectively. At the terminal, the U, V, and W phases of the three-phase coils of the compressor are respectively connected to the midpoint of the branch bridge arm of the corresponding U, V, and W three-way IGBT. When the outdoor temperature is lower than the set temperature, the compressor will heat its own coil before starting to melt the lubricating oil, and then start the compressor normally to ensure that the compressor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com