Potential difference meter

A technology of potentiometer and resistance, applied in the field of potentiometer, can solve the problems of complex structure of switch and instrument, increase of instrument volume, measurement data out of tolerance and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

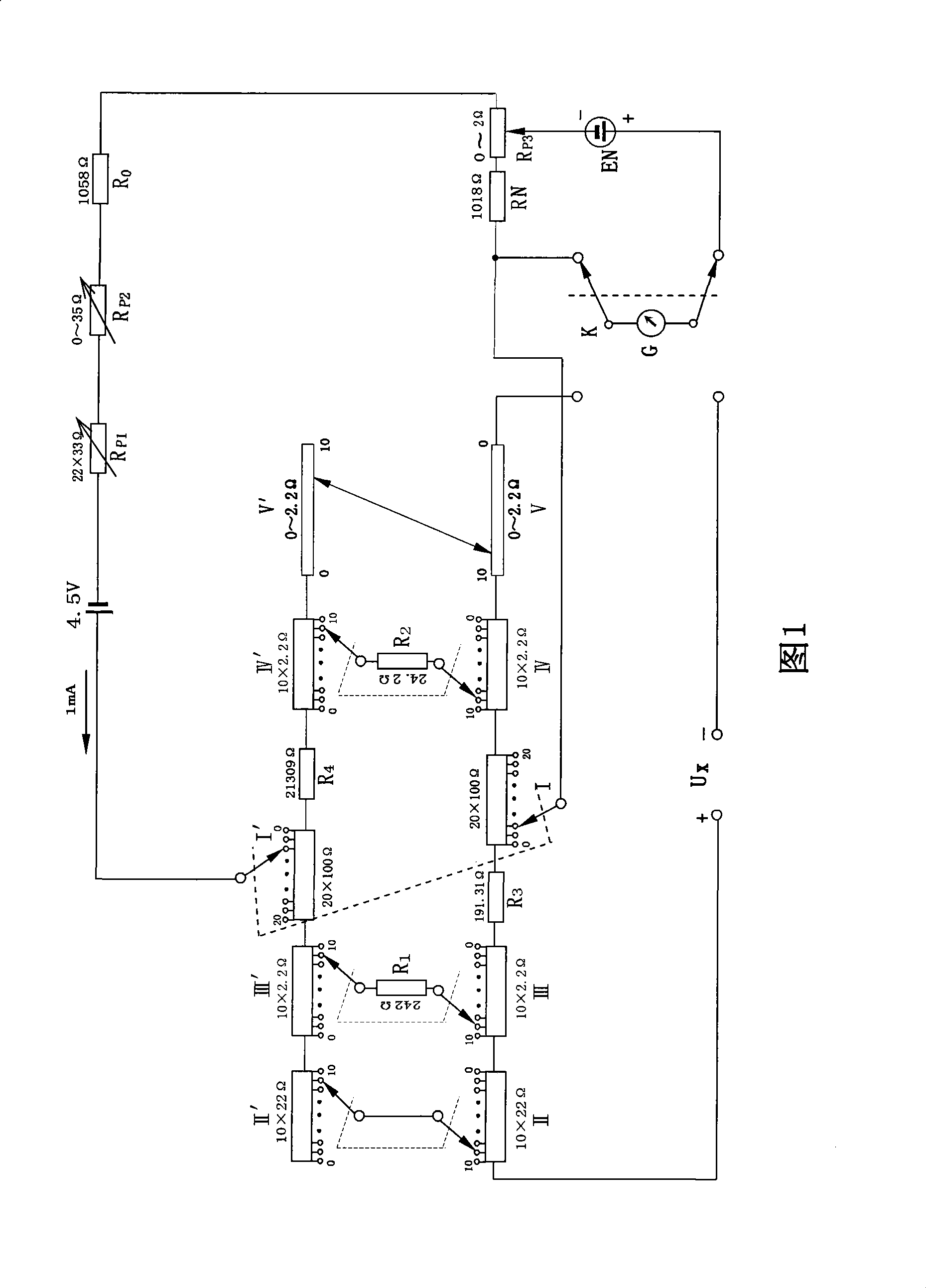

Embodiment 1

[0030] Example 1, in Figure 1, when the four stepping disks and one double-sliding wire disk are all set to "0", the resistance value on the left side between the two brushes of the first stepping disk is equal to 2334.31Ω, and the resistance value on the right side is equal to 23343.1 Ω, therefore, 10 / 11 of the total current between the two brushes of the first step disc flows on the left, and 1 / 11 flows on the right. When each step disc is placed with other contacts, the resistance added by the measuring disc in each step disc is equal to the resistance decreased by the replacement disc, so no matter what value is set on the four step discs and one double-slide disc, the first step The resistance values on the left and right sides between the two brushes entering the plate remain unchanged.

[0031] The standard operating current of the potentiometer is 1mA, the left current between the two brushes of the first step plate is 10 / 11mA, and the right current is 1 / 11mA. The t...

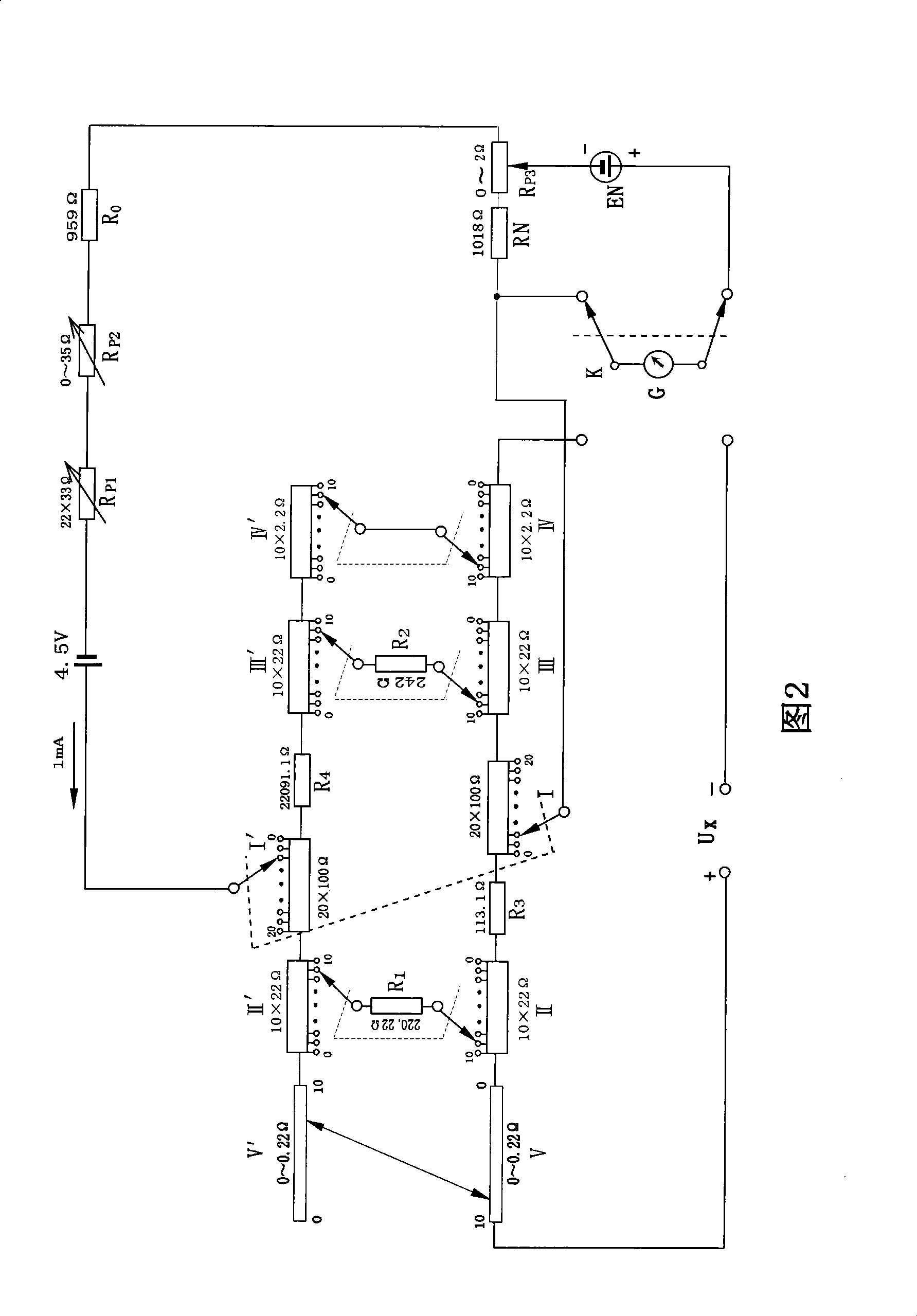

Embodiment 2

[0041] Embodiment 2, in Figure 2, when the four stepping disks and one double-sliding wire disk are all set to "0", the resistance on the left between the two brushes of the first stepping disk is equal to 2443.21Ω, and the resistance on the right is equal to 24432.1Ω, The total resistance between the two brushes of the first stepping disc is 2221.1Ω, so 10 / 11 of the total current between the two brushes of the first stepping disc flows on the left side, and 1 / 11 flows on the right side. When four stepping disks and one double-sliding wire disk are set to other indication values, the increased resistance of the measuring disk is equal to the reduced resistance of the replacement disk, so no matter what indication value is set on four stepping disks and one double-sliding wire disk, the first The resistance values on the left and right sides between the two brushes of the stepping disk remain unchanged, and the total resistance of the circuit remains unchanged.

[0042]The st...

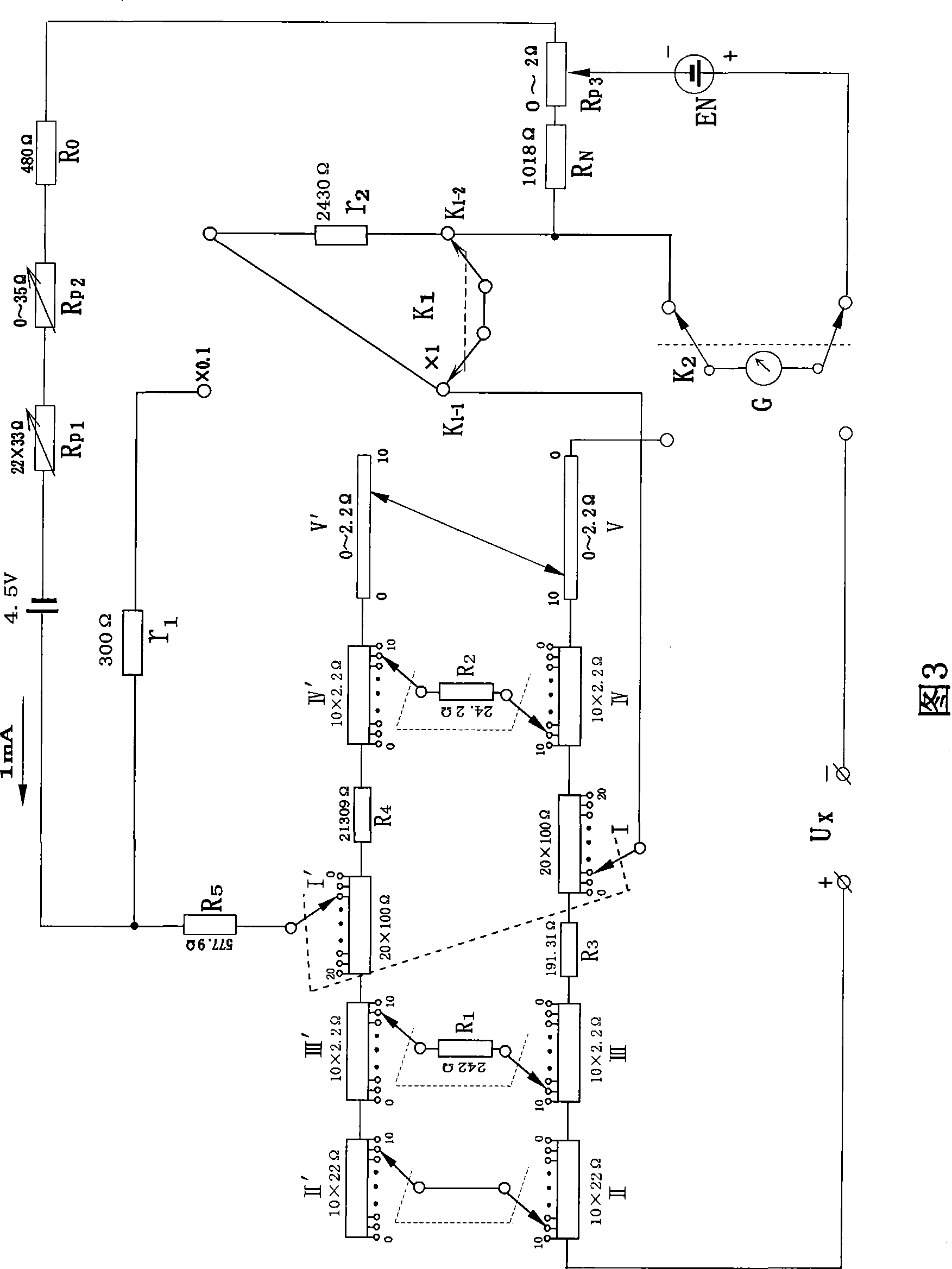

Embodiment 3

[0051] Embodiment 3, in Fig. 3, when the four stepping disks and one double sliding wire disk are all set to "0", the resistance value on the left side between the two brushes of the first stepping disk is equal to 2334.31Ω, and the resistance value on the right side is equal to 23343.1 Ω, therefore, 10 / 11 of the total current between the two brushes of the first step disc flows on the left, and 1 / 11 flows on the right. When each step disc is placed with other contacts, the resistance added by the measuring disc in each step disc is equal to the resistance decreased by the replacement disc, so no matter what value is set on the four step discs and one double-slide disc, the first step The resistance values on the left and right sides between the two brushes entering the plate remain unchanged.

[0052] The standard operating current of the potentiometer is 1mA, the left current between the two brushes of the first step plate is 10 / 11mA, and the right current is 1 / 11mA. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com