Parameter regulation system and method for controlling DC generator speed by PID

A parameter adjustment system, DC motor technology, applied in the direction of DC motor speed/torque control, control system, electric speed/acceleration control, etc. System debugging is time-consuming and labor-intensive, to achieve the effect of saving energy and time, good static performance and dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

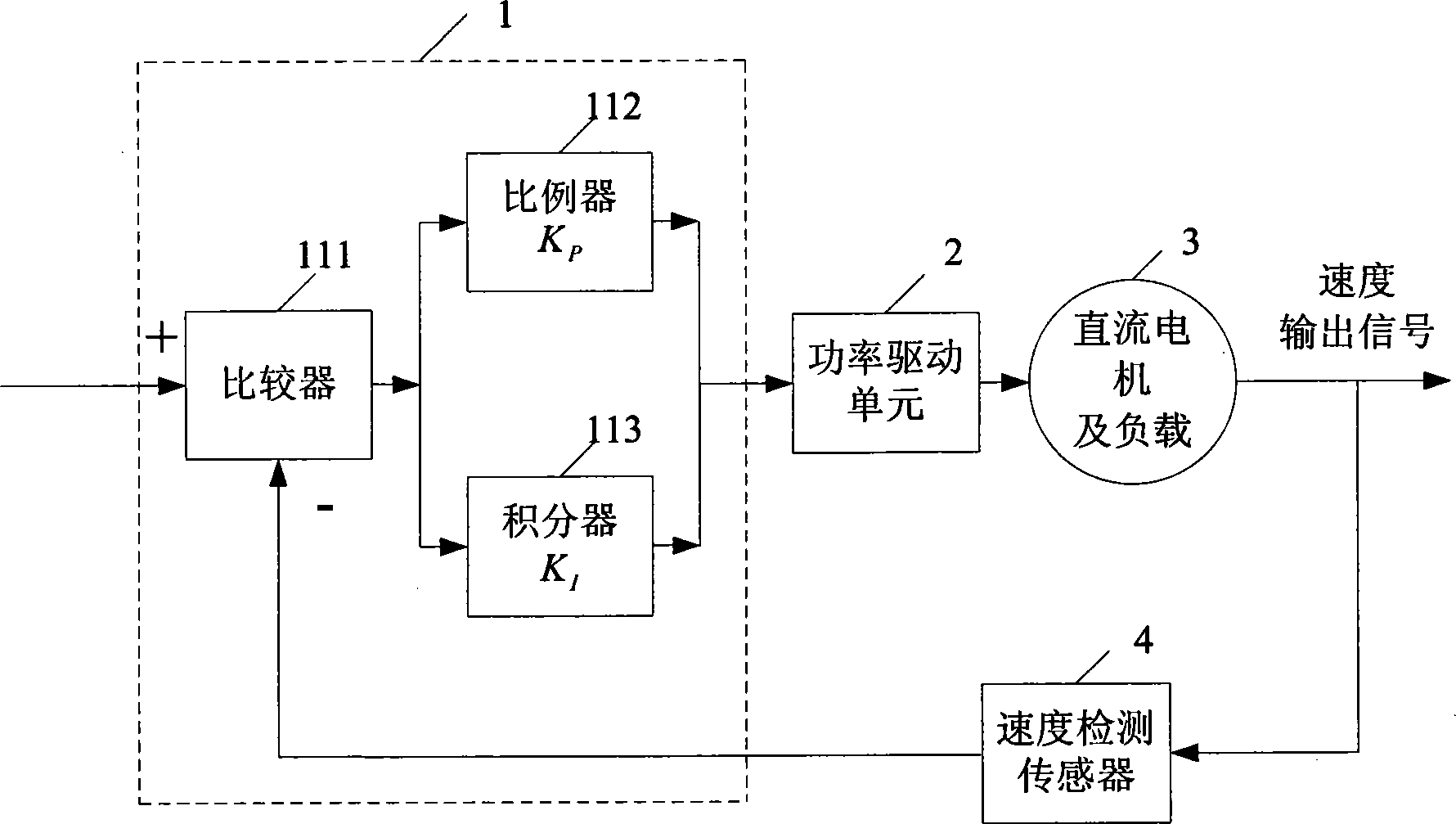

[0021] Such as figure 1 shown. The parameter adjustment system of the DC motor speed PID control of the present invention includes a controller 1, a power drive unit 2, a DC motor and a load 3, and a speed detection sensor 4, wherein the controller 1 is composed of a comparator 111, a proportioner 112, and an integrator 113. The output end of comparator 111 is connected with the input end of proportional device 112, the input end of integrator 113 respectively, and the output end of proportional device 112, the output end of integrator 113 is connected with the input end of power drive unit 2, and power drive unit The output end of 2 is connected with the input end of DC motor and load 3, the output end of DC motor and load 3 is connected with the input end of speed detection sensor 4, the output end of speed detection sensor 4 is connected with the input end of comparator 111.

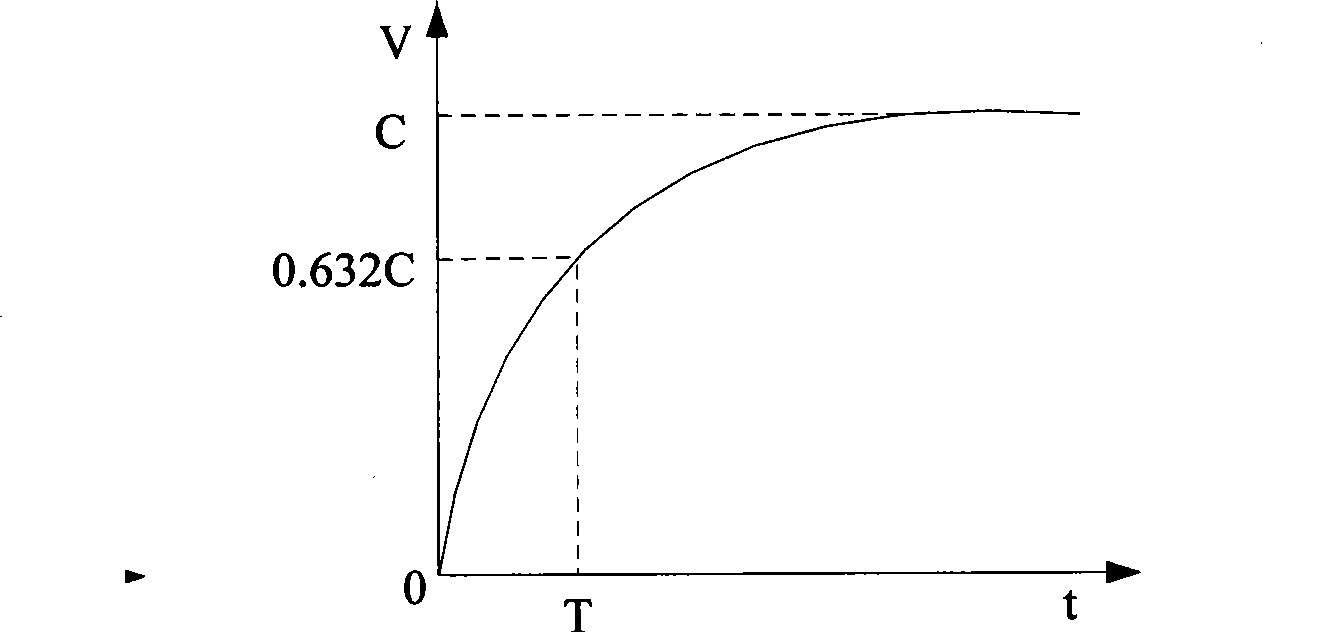

[0022] combine figure 1 , figure 2 , image 3 Describe the adjustment method of the parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com