Low-voltage side voltage regulating and dynamic compensating device for electric arc furnace

A technology of voltage regulation and dynamic compensation, which is applied to electric heating devices, reactive power adjustment/elimination/compensation, reactive power compensation, etc. It can solve problems such as shortened maintenance cycle, extended product production cycle, and reduced safety of transformers. Short power outage time requirements, easy management and benefit analysis, and high degree of automation and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

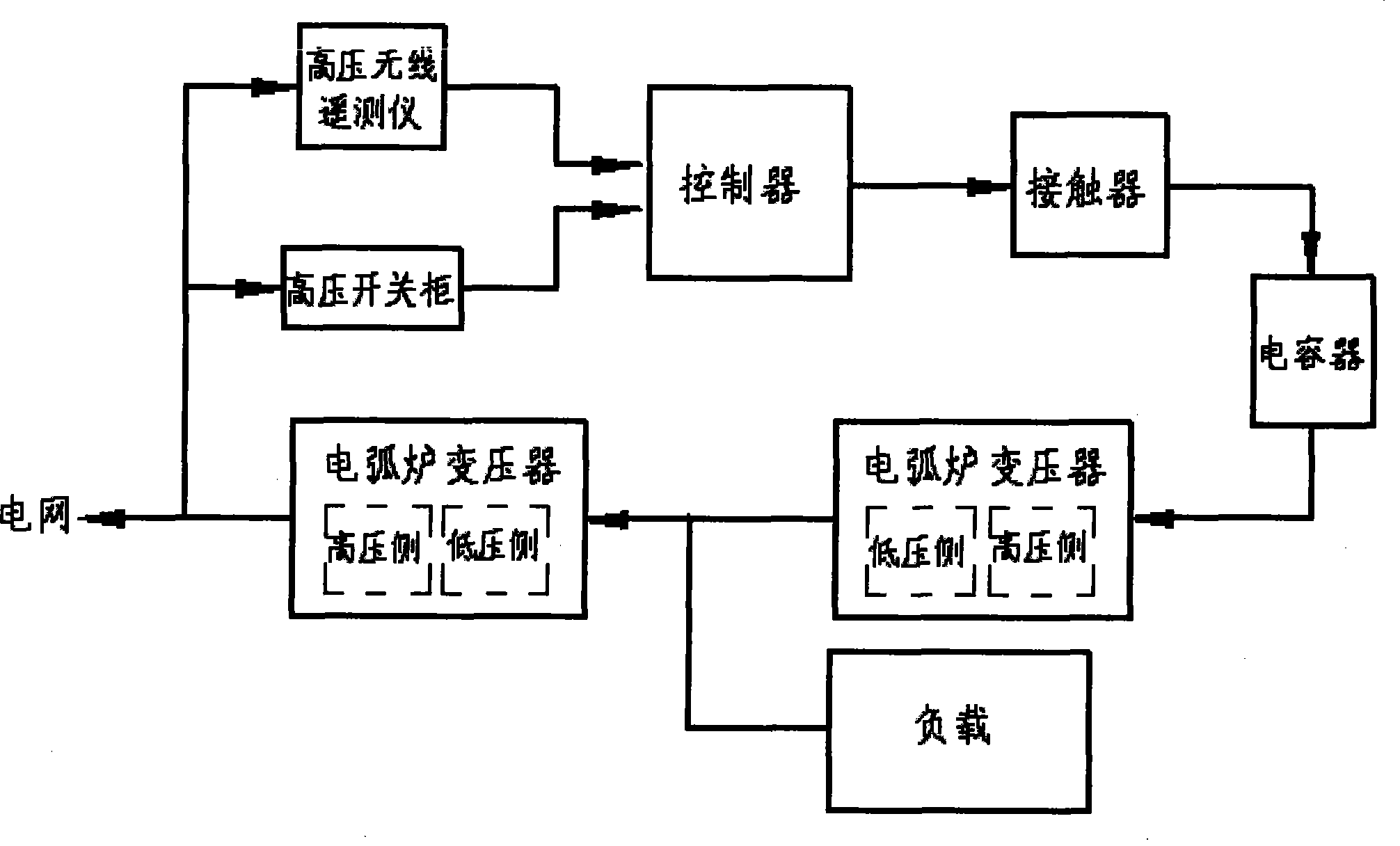

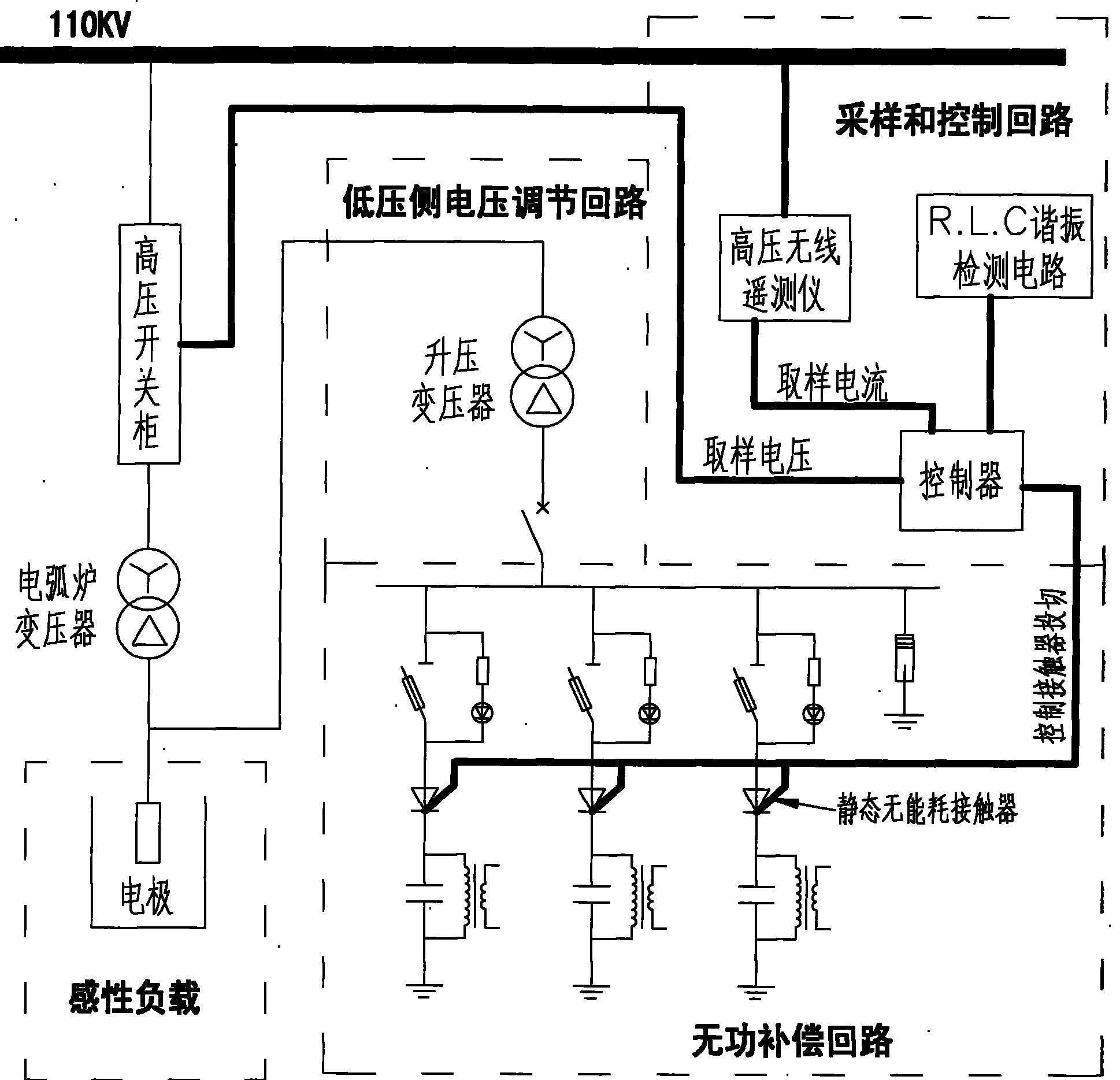

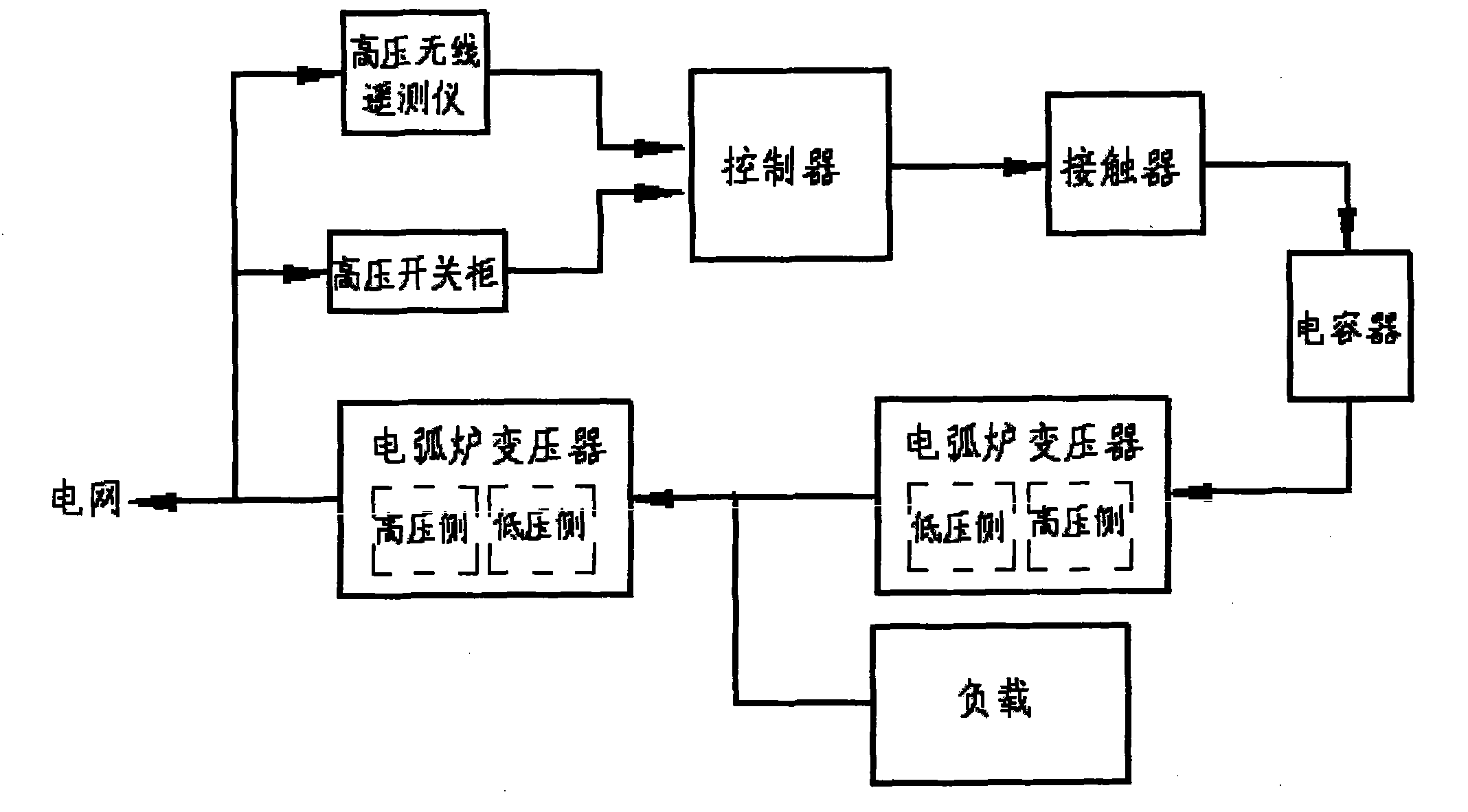

[0022] Such as figure 1 As shown, the invention discloses a voltage regulation and dynamic compensation device on the low-voltage side of an electric arc furnace, including a high-voltage wireless remote meter, a high-voltage switch cabinet, a controller, a contactor, a compensation capacitor, a step-up transformer, an electric arc furnace transformer and a load; its characteristics It consists in: connecting the high-voltage side of the electric arc furnace transformer to the power grid, and boosting the low-voltage side of the step-up transformer at the low-voltage side of the electric arc furnace transformer, and then installing the compensation capacitor on the high-voltage side of the step-up transformer. The current transformer in the high-voltage switchgear and the voltage transformer in the high-voltage switchgear collect the current and voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com