Exhaust system comprising catalysed soot filter

A technology of dust filter and exhaust system, which is applied in the direction of exhaust device, machine/engine, noise reduction device, etc., and can solve problems such as difficulty, impossibility of direct measurement, damage of thermocouple or filter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

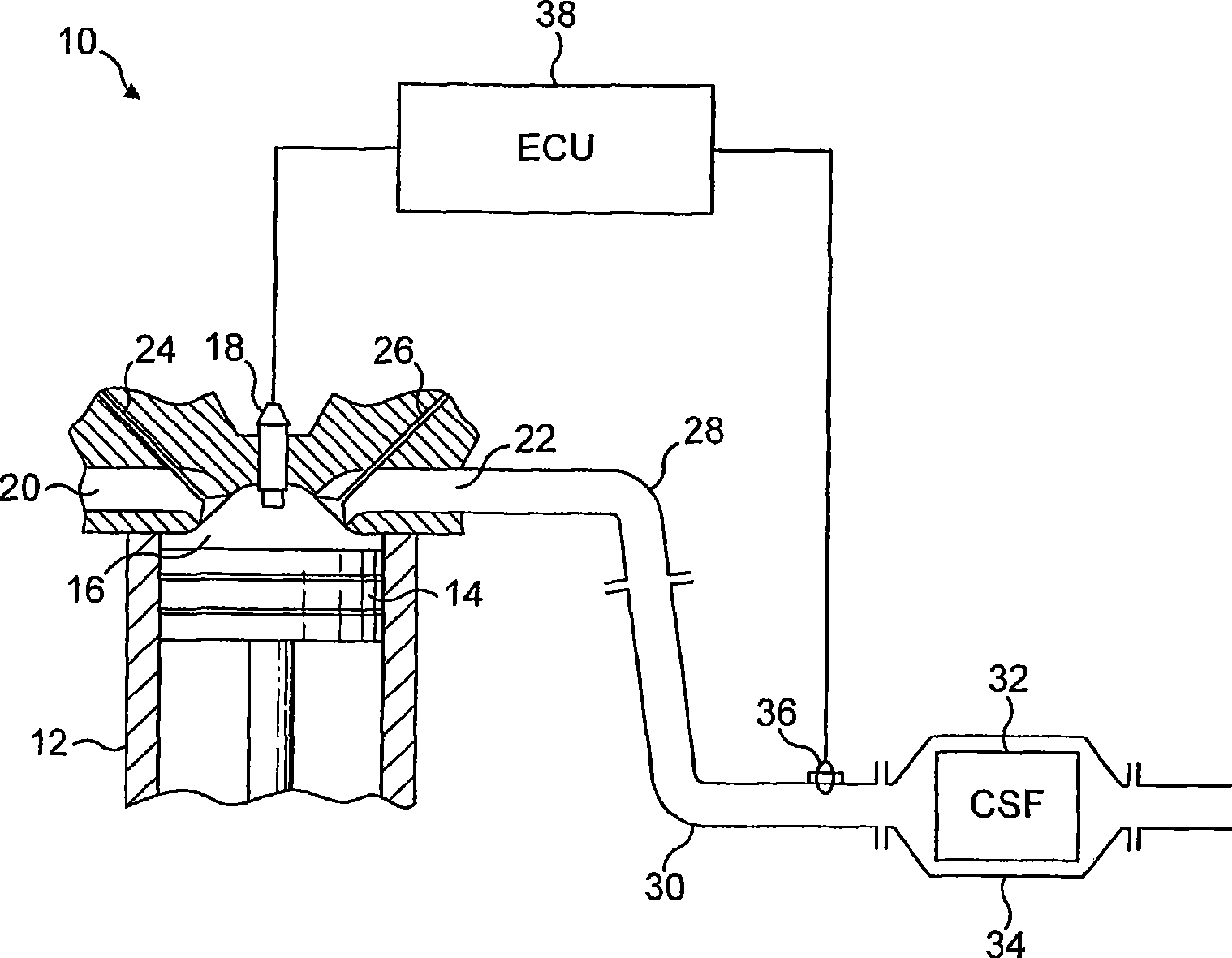

[0036] refer to figure 1 , the apparatus according to the invention is denoted by reference numeral 10, wherein 12 is a light diesel engine body, 14 is a piston, 16 is a combustion chamber, 18 is a conventional rail fuel injector, 20 is a suction port, 22 is a discharge port, 24 is a suction port Gas valve, 26 is a discharge valve, 28 is a discharge manifold, 30 is a discharge pipe, 32 is a CSF, 34 is a tank including a discharge gas diffuser to contain the CSF and keep it in communication with the discharge pipe, 36 is a sensor, including A catalyzed thermocouple junction and an uncatalyzed reference thermocouple junction, and 38 is an engine control unit (ECU) which, in use, is programmed to control common rail fuel injectors during active regeneration of the CSF in response to signals from Detection input of sensor 36.

[0037] In use, the ECU 38 determines the number of miles since the last active regeneration. When the mileage exceeds a predetermined amount, for example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com