Photomultiplier and radiation sensor

A photomultiplier tube and radiation detection technology, which is applied in the direction of electron multiplier tubes, electrode devices with multiple dynodes, detailed information of electron multipliers, etc., can solve problems such as insufficient connections, and achieve high detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0045] Figure 1 to Figure 22 It is a diagram showing a radiation detection device including a photomultiplier tube according to an embodiment of the present invention. In each figure, the same code|symbol is attached|subjected to the substantially same part, and repeated description is abbreviate|omitted. In addition, in the following description, terms such as "upper" and "lower" are used for convenience based on the states shown in the drawings.

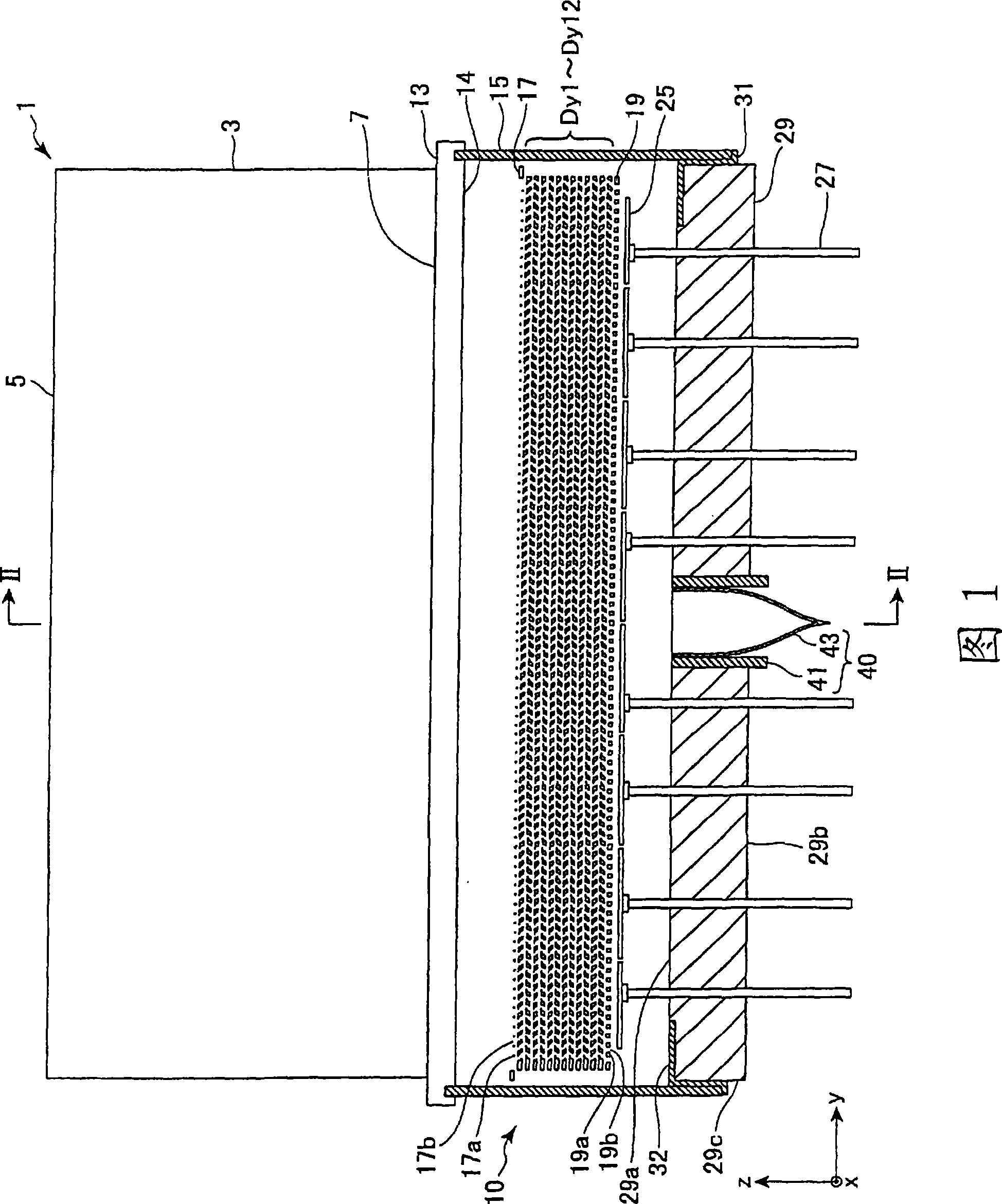

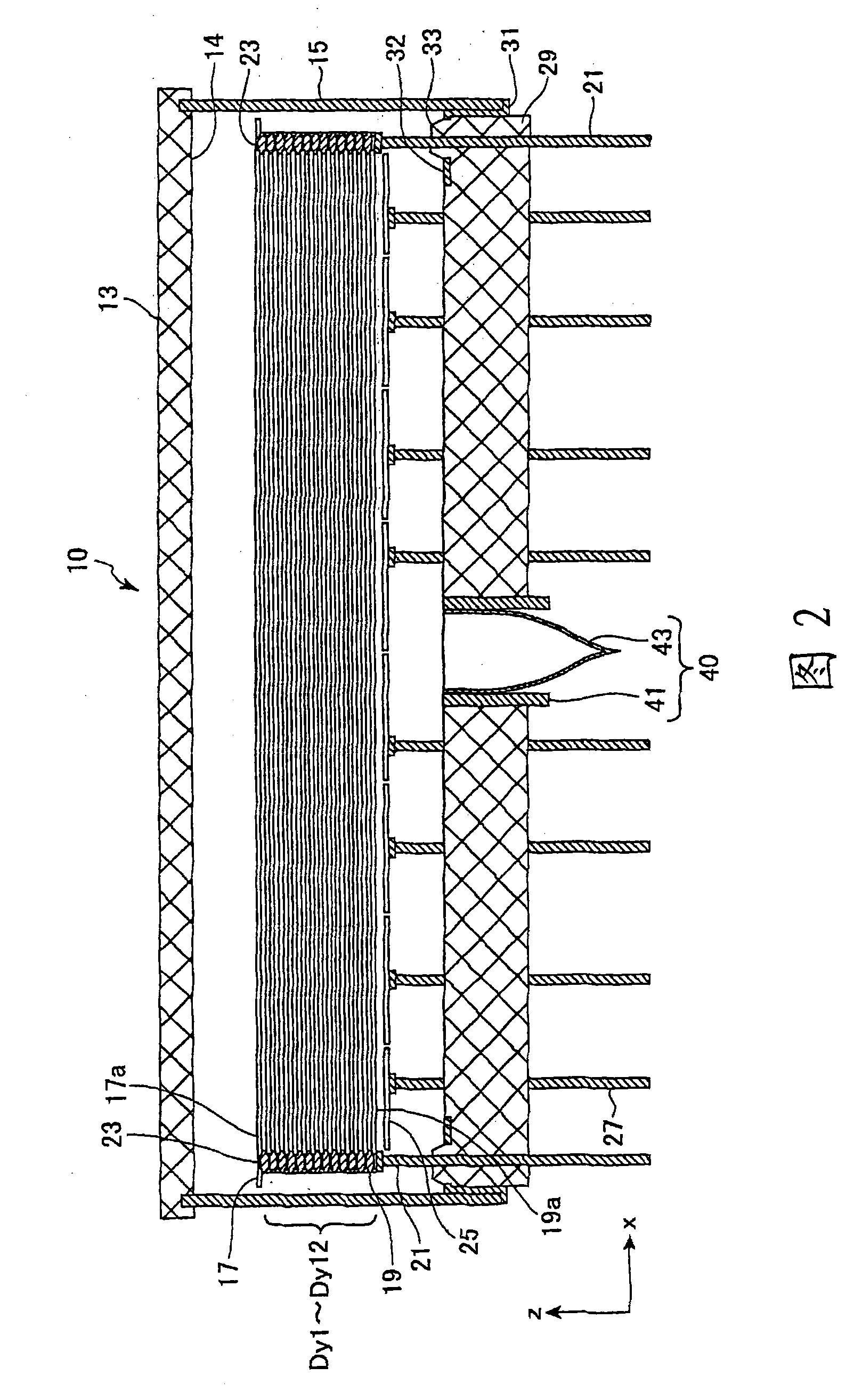

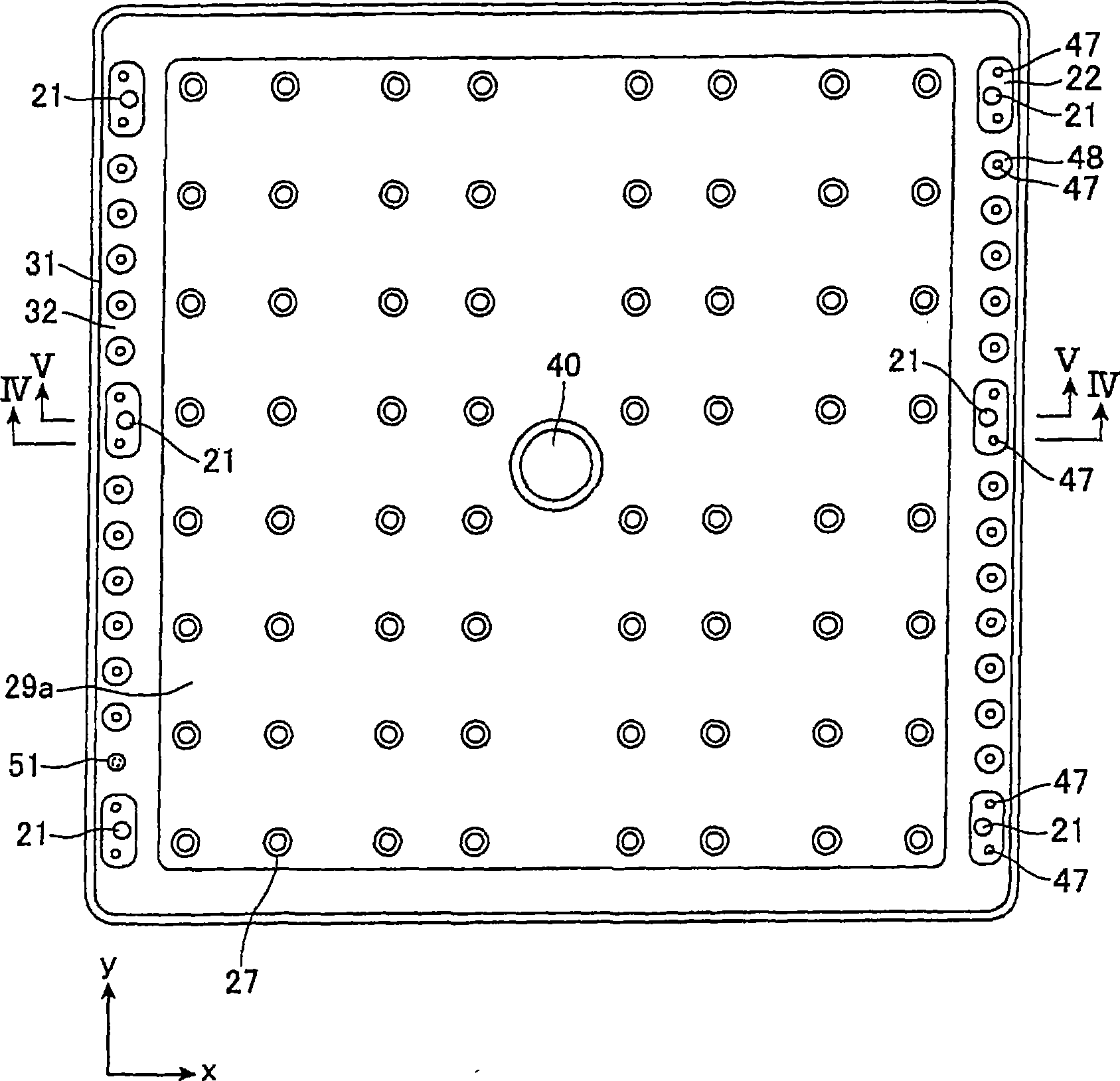

[0046] figure 1 is a schematic cross-sectional view of the radiation detection device 1 of the present embodiment, figure 2 is along figure 1 A schematic cross-sectional view of the photomultiplier tube 10 on the II-II plane of FIG. Such as figure 1 , figure 2 As shown, the radiation detection device 1 is a device that detects incident radiation and outputs it as a signal, and has: a scintillator (scintillator) 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com