Waste water processing method

A waste water treatment, waste water technology, applied in the direction of water/sewage treatment, water/sludge/sewage treatment, separation method, etc., can solve the problem of high cost of waste water treatment, and achieve the effect of cost reduction, cost reduction, and simple waste water treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

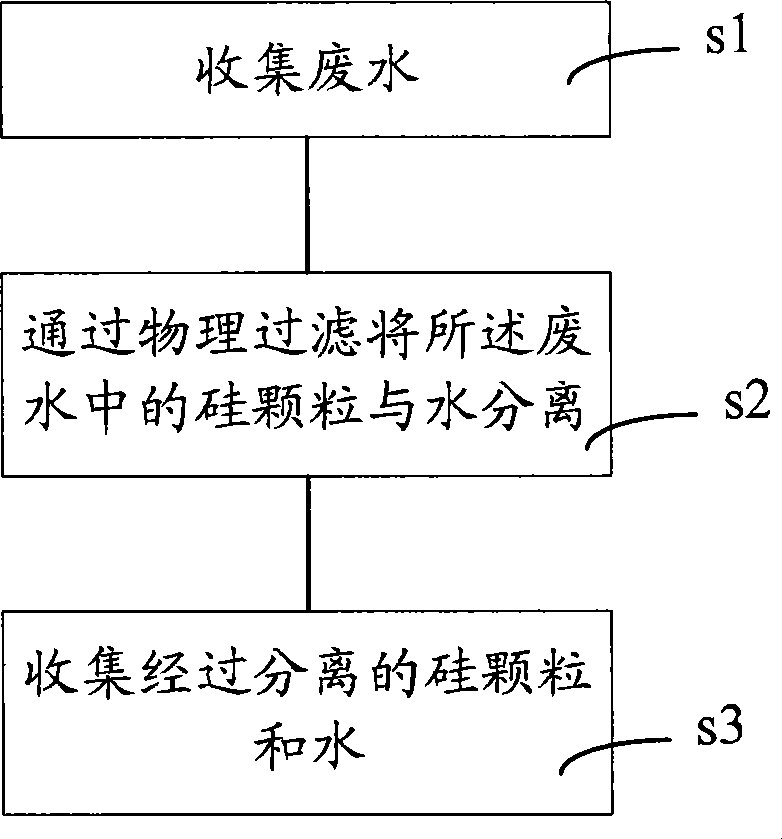

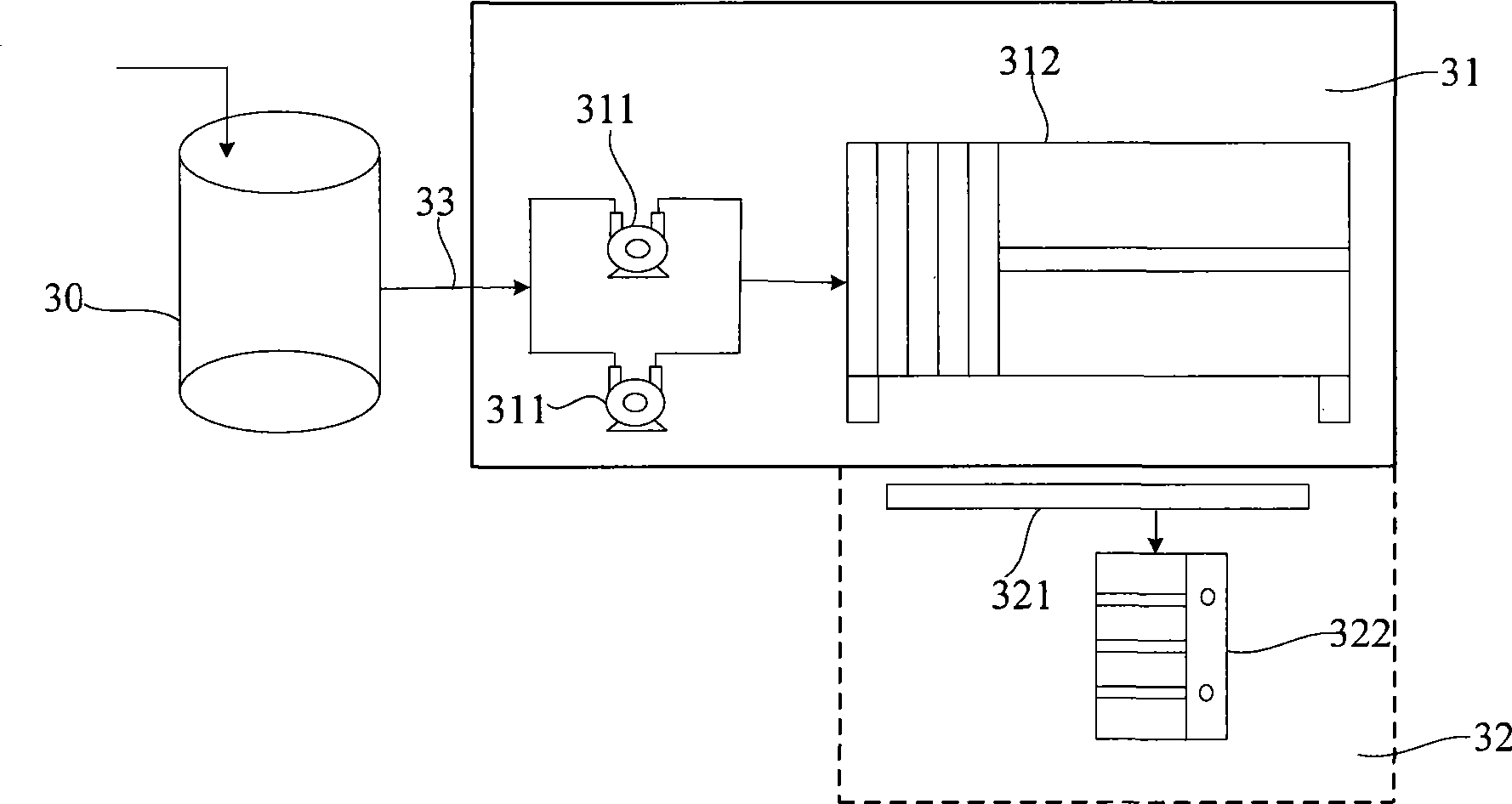

[0027] The waste water treatment method of the invention separates silicon particles and water in the waste water through physical filtration without adding chemicals, so that the waste water treatment process is simple and the cost is reduced.

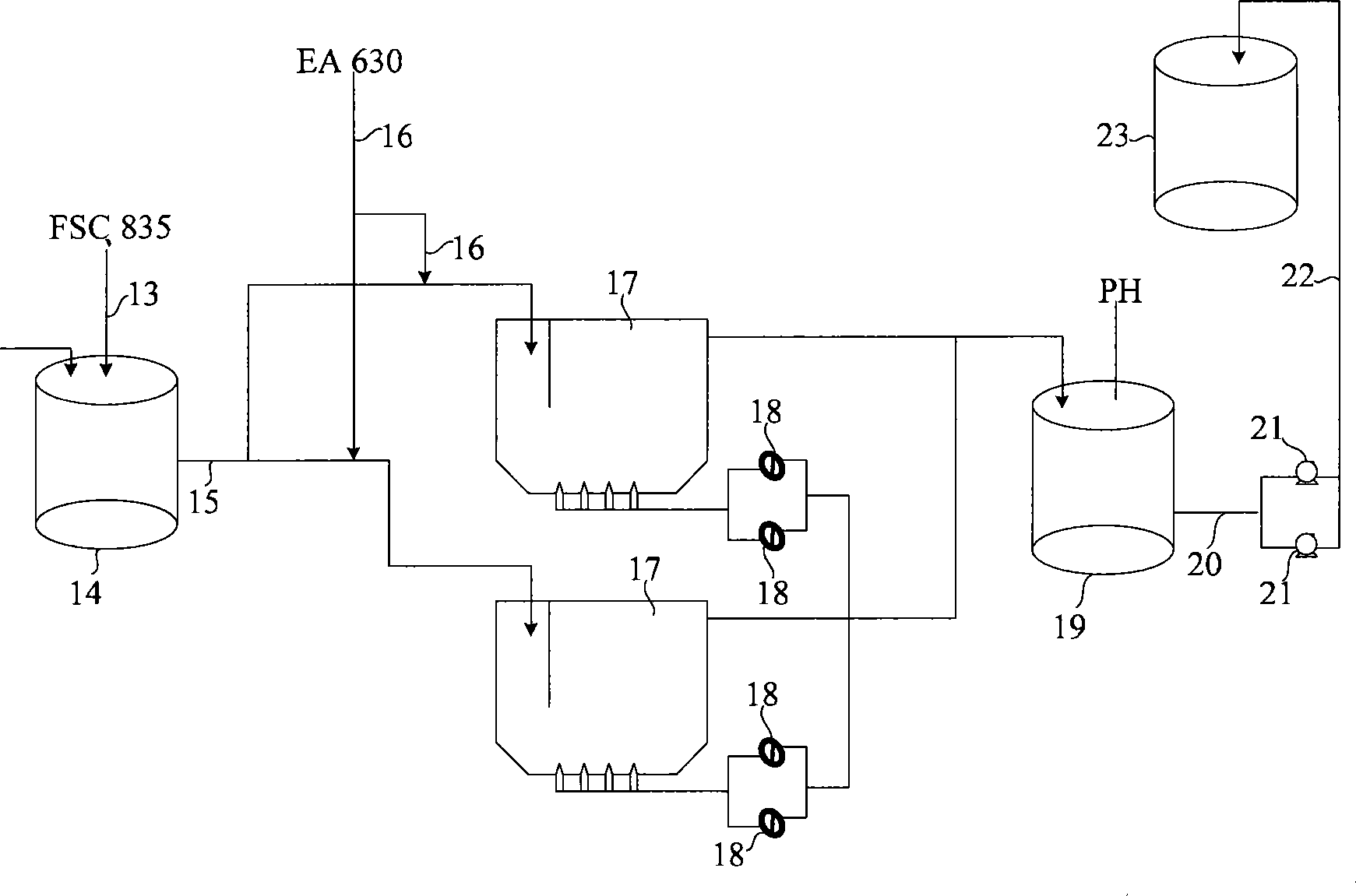

[0028] As mentioned above, before the semiconductor chip is packaged, the back of the semiconductor wafer needs to be thinned and the semiconductor chip is cut off from the semiconductor wafer, and then a single or several semiconductor chips are packaged, wired and tested. The backside thinning process is a process of removing part of the silicon material on the backside of the semiconductor wafer by grinding equipment. For example, for a 300mm semiconductor wafer, its thickness is generally 700 to 800mm, and it usually needs to be thinned to 200 to 400mm before packaging; The dicing process cuts semiconductor chips from semiconductor wafers by using a dicing saw with a diamond blade. No matter in the grinding or cutting process, a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com