High strength aluminum alloy anodizing electrolyte, preparation method of high strength aluminum alloy anode oxide film and high strength aluminum alloy workpiece

An anodic oxidation film and anodic oxidation technology, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of reducing the fatigue resistance of the substrate, low porosity, polluting the environment, etc., and achieve suitable industrial promotion and application , The wastewater treatment process is simple, the preparation process is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

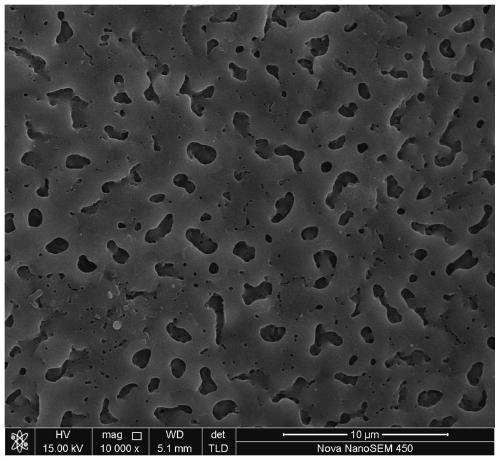

Image

Examples

Embodiment 1

[0036] (1) Configure 2L of anodic oxidation electrolyte including 0.1mol / L phytic acid, the steps are as follows:

[0037] Add 1L of deionized water to the stainless steel electrolytic cell;

[0038] Then slowly add 132mL of phytic acid solution with a mass fraction of 70% and stir until mixed evenly;

[0039] Then add water to 2L, and adjust the pH to 2.0-2.5 with 1mol / L KOH solution;

[0040] Let stand for 24h.

[0041] (2) The preparation method of 2024 aluminum alloy (Al-Cu-Mg series) anodic oxidation film, the steps are as follows:

[0042] Put the 2024 aluminum alloy in the alkaline etching solution at 50°C for 3 minutes, and then wash it with hot water and cold water in turn. The alkaline etching solution is prepared by dissolving sodium hydroxide and sodium sulfide in deionized water. The hydrogen in the alkaline etching solution is The concentration of sodium oxide is 60g / L, and the concentration of sodium sulfide is 5g / L;

[0043] Immediately immerse the 2024 alumi...

Embodiment 2

[0047] (1) Configure 2L of anodic oxidation electrolyte including 0.2mol / L phytic acid, the steps are as follows:

[0048] Add about 1L of deionized water to the stainless steel electrolytic cell;

[0049] Then slowly add 132 mL of phytic acid solution with a mass fraction of 70% and stir until completely dissolved;

[0050] Then add water to 2L, and adjust the pH to 2.0-2.5 with 1mol / L KOH solution;

[0051] Let stand for 24h.

[0052] (2) The preparation method of 2024 aluminum alloy (Al-Cu-Mg series) anodic oxidation film, the steps are as follows:

[0053] Put the 2024 aluminum alloy in the alkaline etching solution at 50°C for 3 minutes, and then wash it with hot water and cold water in turn. The alkaline etching solution is prepared by dissolving sodium hydroxide and sodium sulfide in deionized water. The hydrogen in the alkaline etching solution is The concentration of sodium oxide is 60g / L, and the concentration of sodium sulfide is 5g / L;

[0054] Immediately immer...

Embodiment 3

[0058] The preparation method of anodic oxidation electrolyte is identical with embodiment 2;

[0059] The preparation method of 2024 aluminum alloy (Al-Cu-Mg series) anodized film, the steps are as follows:

[0060] Put the 2024 aluminum alloy in the alkaline etching solution at 50°C for 3 minutes, and then wash it with hot water and cold water in turn. The alkaline etching solution is prepared by dissolving sodium hydroxide and sodium sulfide in deionized water. The hydrogen in the alkaline etching solution is The concentration of sodium oxide is 60g / L, and the concentration of sodium sulfide is 5g / L;

[0061] Immediately immerse the 2024 aluminum alloy after the cold water washing treatment in a 30% volume concentration nitric acid solution for 30 seconds, and then perform water washing treatment;

[0062] Put the 2024 aluminum alloy after the light treatment in the prepared 0.2mol / L phytic acid electrolyte, and carry out anodic oxidation treatment with direct current at 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com