Automatic power supply device of tyre type gantry crane

A technology of gantry crane and automatic power supply, applied in circuits, current collectors, electrical components, etc., can solve problems such as loss and inability to realize free transition, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

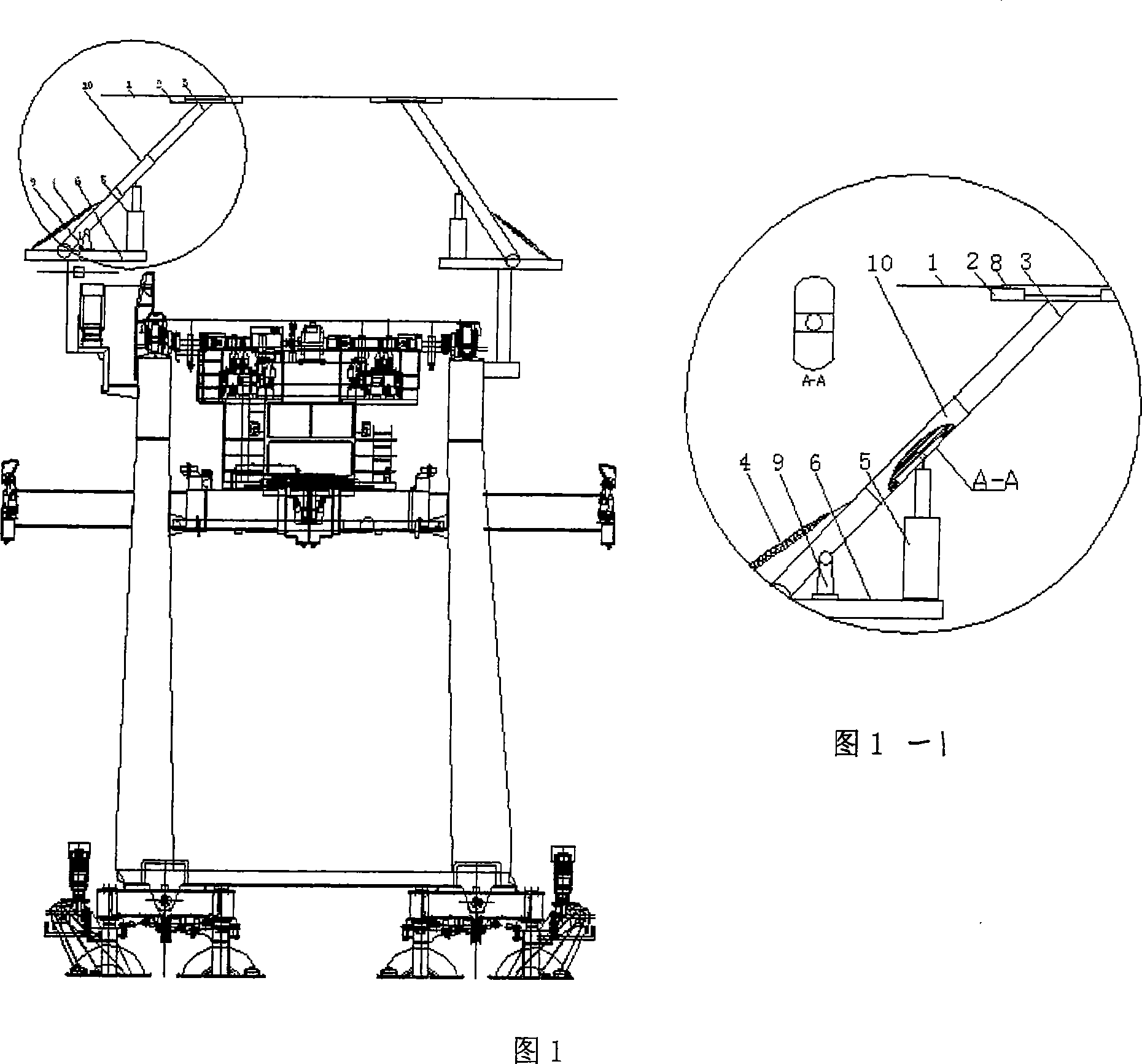

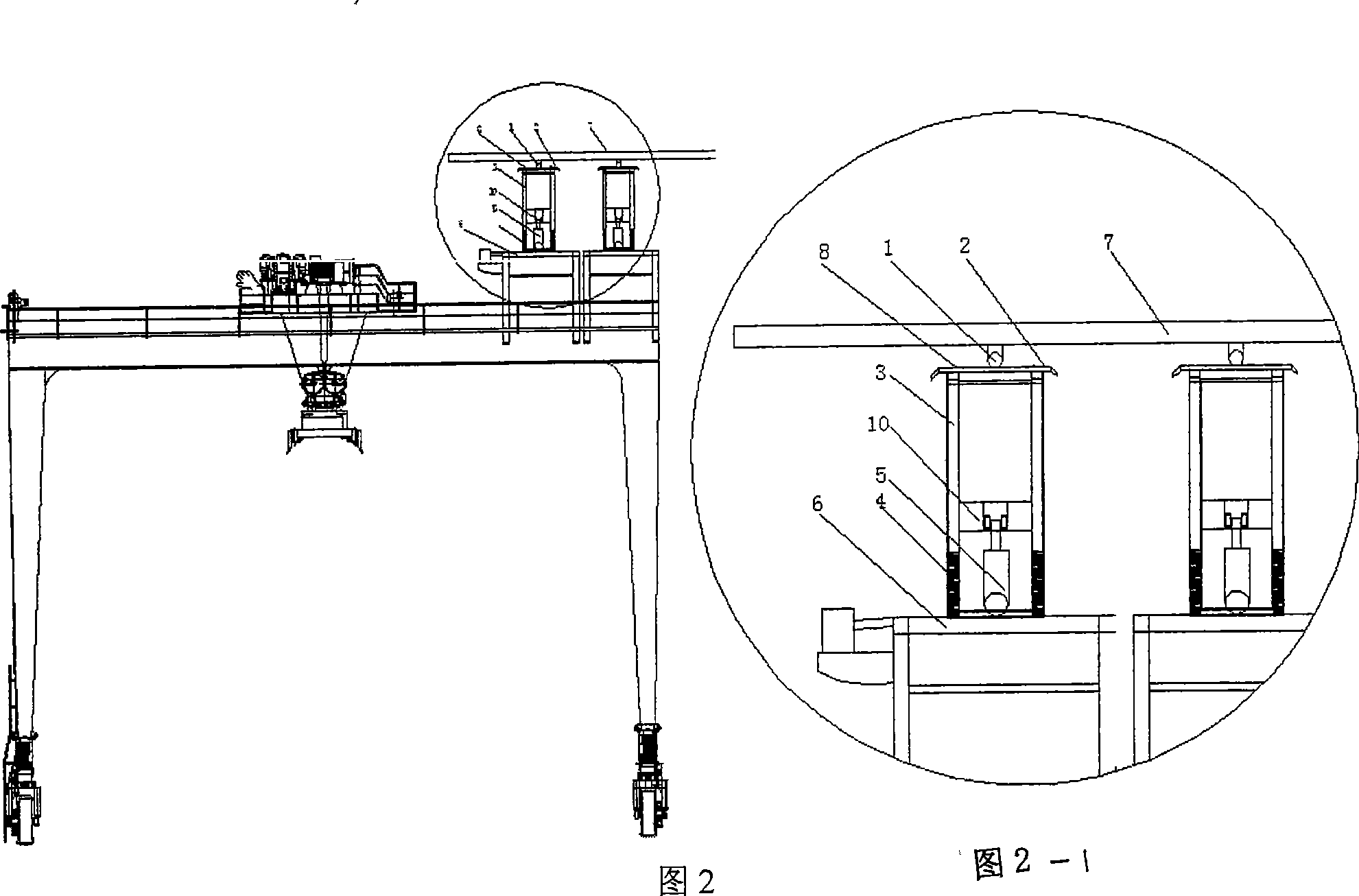

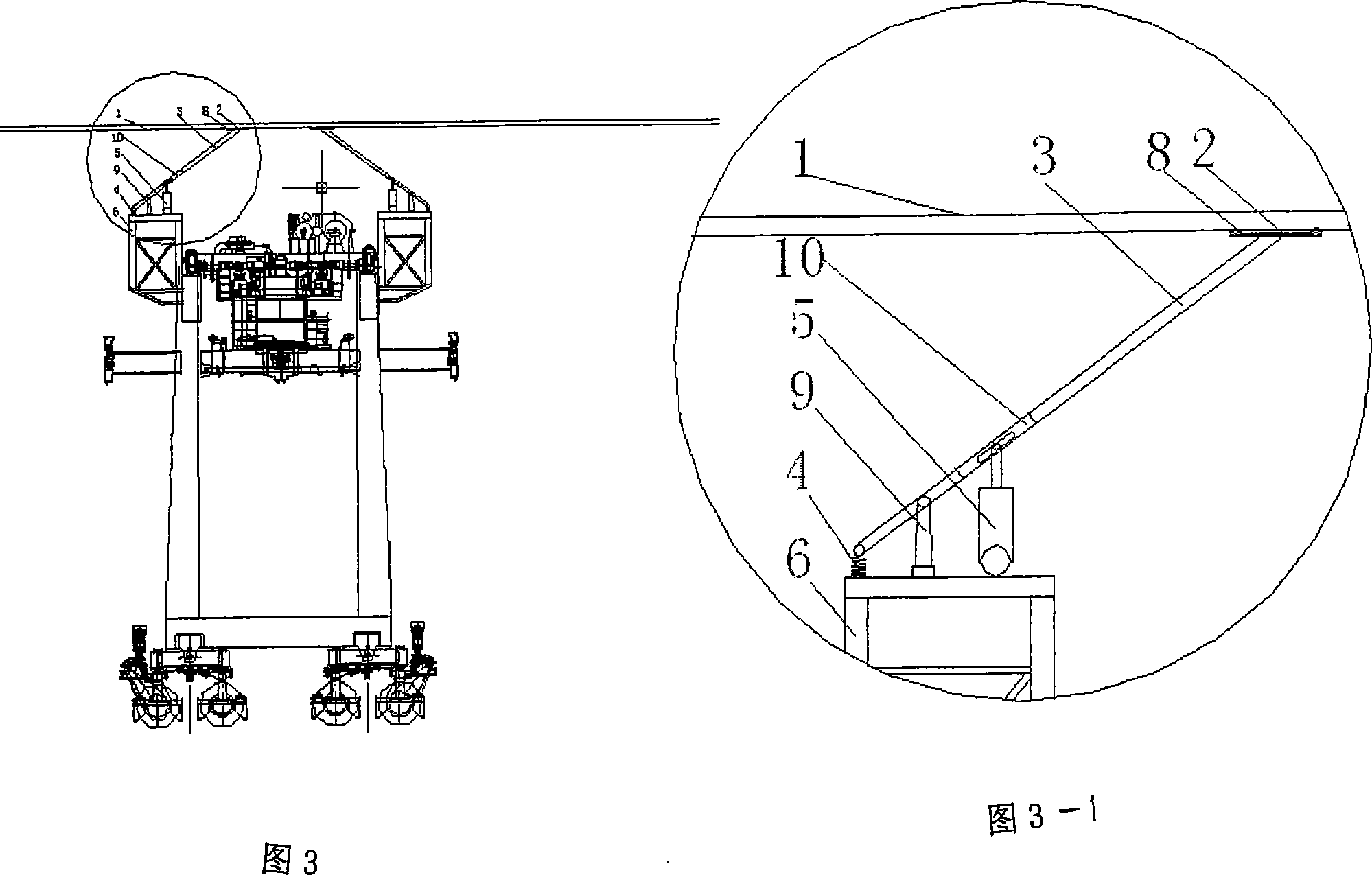

[0019] The structure of the automatic power supply device of the rubber-tyred container gantry crane shown in the figure includes: a pantograph, a support rod, an electro-hydraulic push rod, a spring device, and a deviation sensor. Each pantograph (2) is supported by two parallel support rods (3), so that the pantograph is close to the trolley line (1) to take power, and the pantograph in contact with the neutral line is equipped with a deviation sensor ( 8). One end of each support rod is connected to the pantograph, and the other end is connected to the platform (6) erected on the rubber-tyred container gantry crane with a movable hinge point; one end of the spring device (4) is connected to the support rod (or intermediate connecting rod), and one end It is fixed on the rubber-tyred container gantry crane, and the spring is always in a stretched state; one end of the electro-hydraulic push rod (5) is connected to the middle connecting rod (10), and the other end is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com