Method for monitoring downhole casing strain by using optical fibre sensor

A fiber optic sensor and sensor technology, applied in the directions of measurement, earthwork drilling and production, borehole/well components, etc., can solve the problem of lack of direct monitoring methods for the shape characteristics of casing damage, and achieve the effect of high precision and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

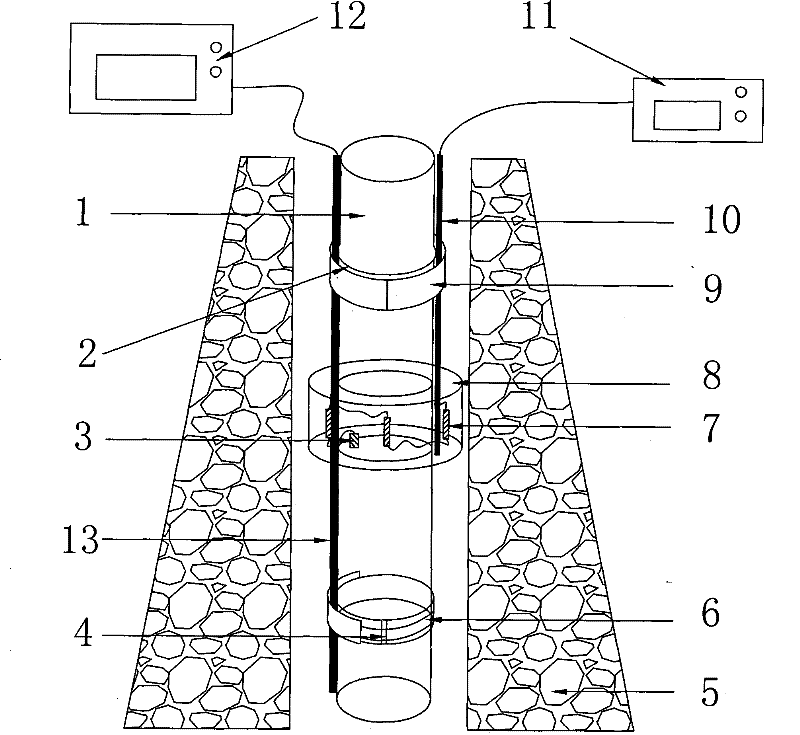

[0020] The present invention will be further described below in conjunction with accompanying drawing:

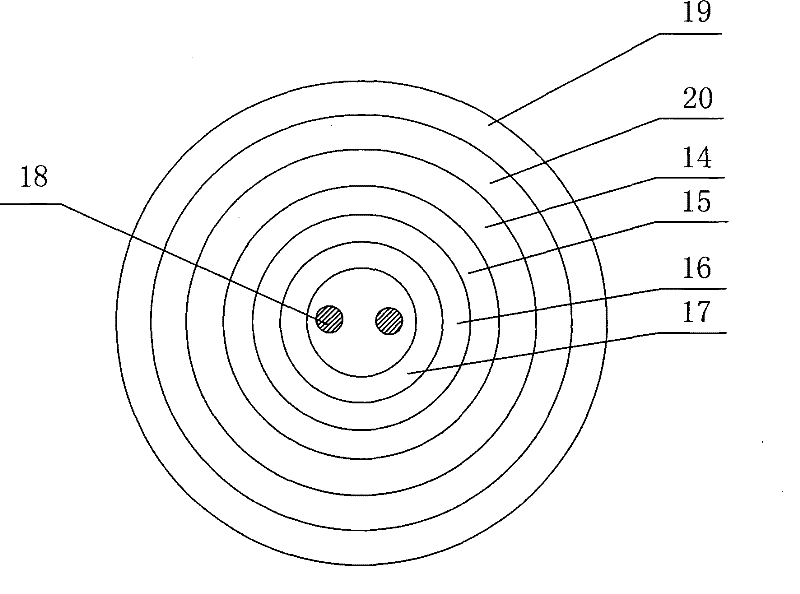

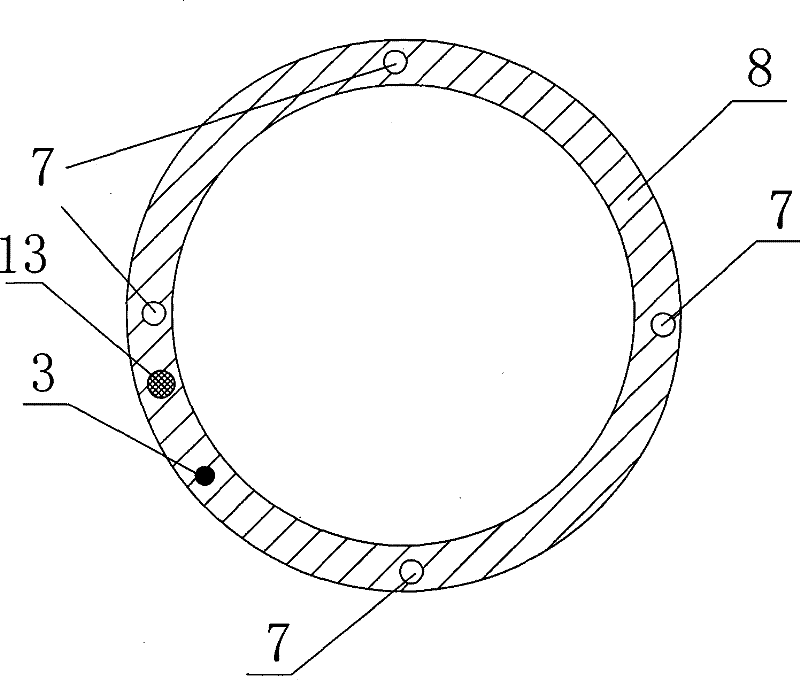

[0021] The main scheme of the present invention is: a fiber grating sensor is arranged along the outer surface of the casing circumferentially, and a ground fiber grating demodulator connected to the fiber grating sensor is used to monitor the circumferential strain of the casing ε θ And obtain the circumferential strain data of the casing, and at the same time arrange the optical fiber Brillouin sensor axially along the outer surface of the casing, and use the ground optical fiber Brillouin demodulator connected to the optical fiber Brillouin sensor to monitor the axial direction of the casing Strain ε z And obtain the casing axial strain data, the obtained casing circumferential strain ε θ and axial strain ε z Substituting the following constitutive equations (1) and (2) of the casing stress and strain in the cylindrical coordinate system, the horizontal maximum princip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com