Detection method for protection slag of continuous casting crystallizer in thermal state lubrication friction state

A continuous casting crystallizer, lubrication and friction technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of simple processing method, inability to realize the detection of mold slag thermal lubrication and friction state, and no practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail through specific embodiments below in conjunction with the accompanying drawings.

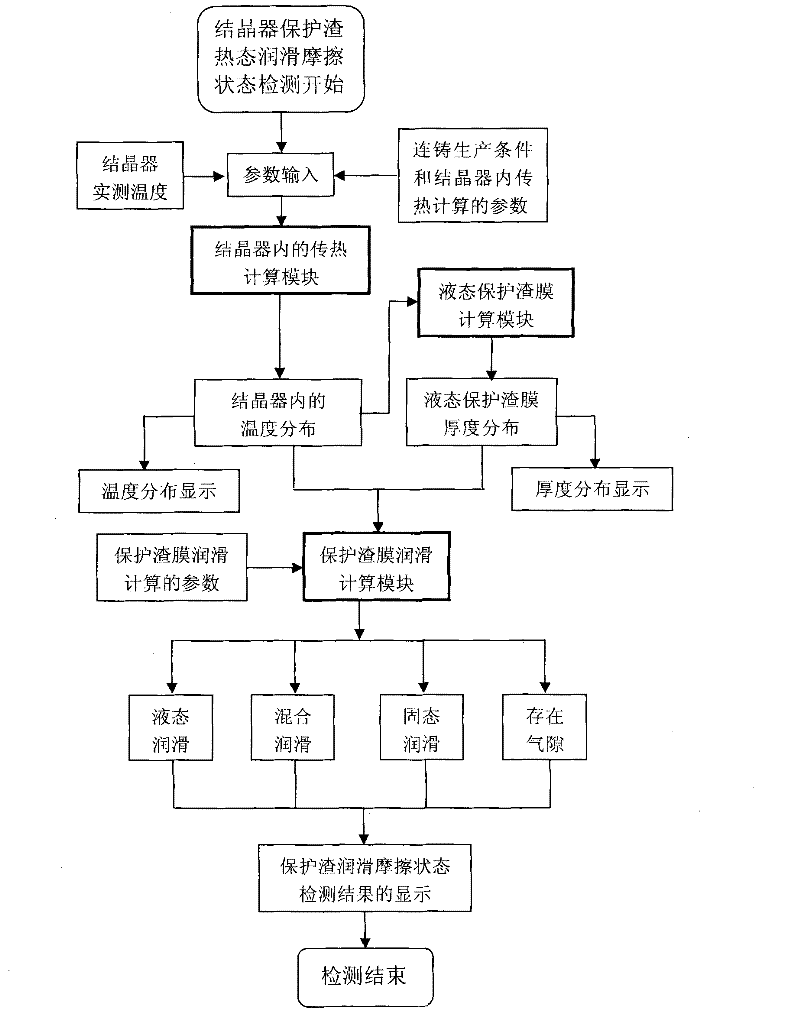

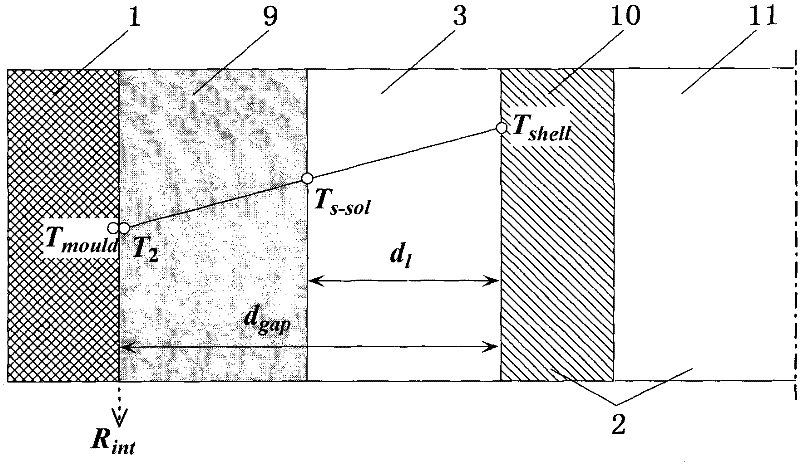

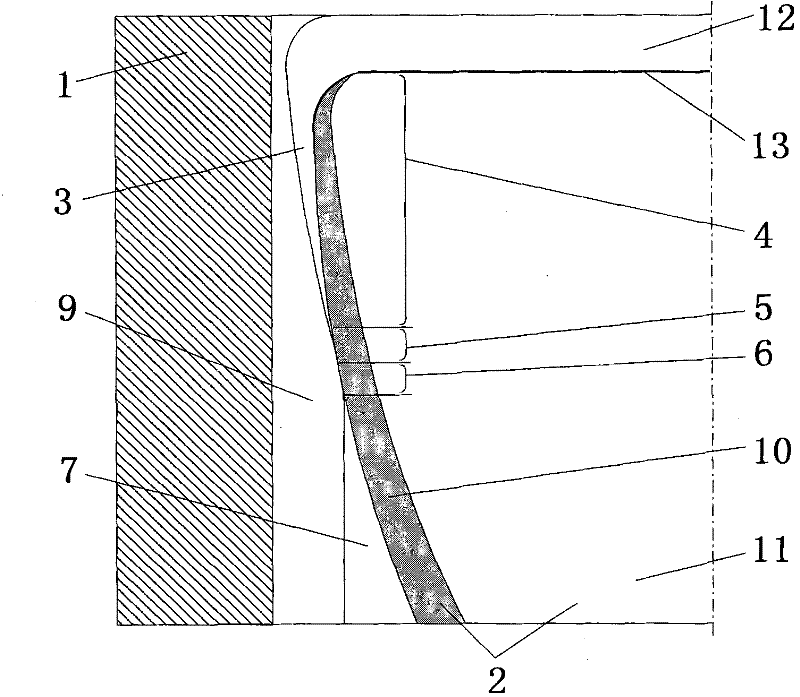

[0046] figure 1 It is a working flow chart of the method for detecting the hot state lubrication and friction state of mold powder. After starting to run the detection program of mold slag hot state lubrication and friction state, first input the actual temperature of the mold, the production conditions of continuous casting and the parameters of heat transfer calculation in the mold into the system, and then enter the heat transfer calculation module in the mold , calculate the temperature distribution in the mold, and display the temperature distribution of the hot surface of the mold and the surface of the slab; secondly, input the temperature distribution data of the hot surface of the mold and the surface of the slab into the liquid mold slag film calculation module, Calculate the thickness distribution of the liquid mold sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com