Cooperating design method of aircraft control system in different areas based on PDM//matlab

A control system and collaborative design technology, applied in instruments, computing, aircraft parts, etc., can solve problems such as the inability to reflect the superiority of SmarTeam, the PDM system does not support Matlab, the browser does not support Matlab, etc., to avoid complex operations, The effect of reducing development cost and enhancing security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

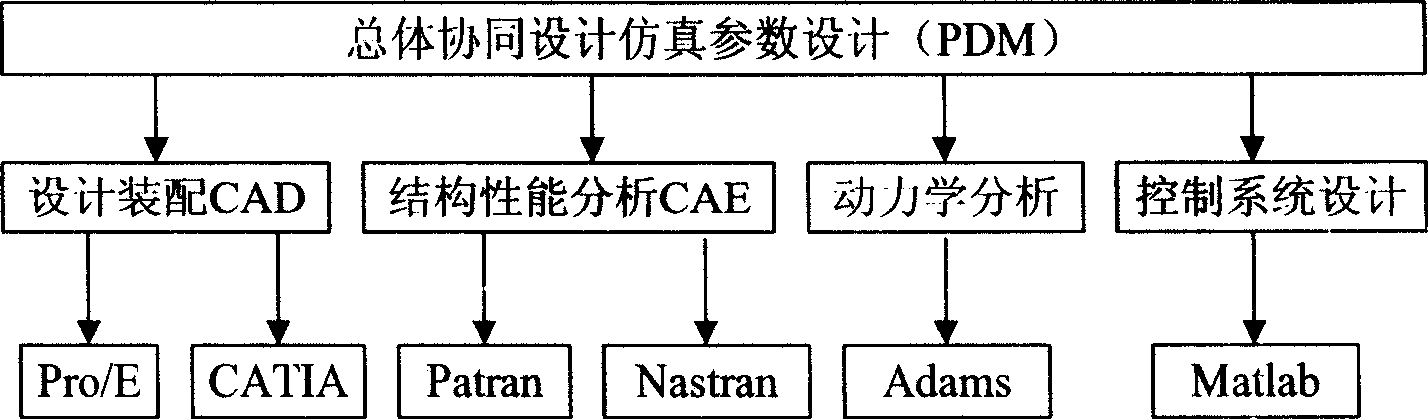

[0023] Taking the design of a certain type of missile as an example, a certain type of missile developed by a research institute is composed of a seeker, a power system, a guidance control device, and a body structure. The simulation system is the object, with parallel work and collaborative simulation as the main line, the work of parallel product development is carried out, including design and assembly, structural performance analysis, dynamic analysis and control system design. The design and assembly are mainly through Pro / E and CATIA is implemented, structural performance analysis is mainly realized through Patran and Nastran, dynamic analysis is mainly realized through Adams, control system design is mainly realized through Matlab, and then various parts are managed through PDM, such as figure 1 shown.

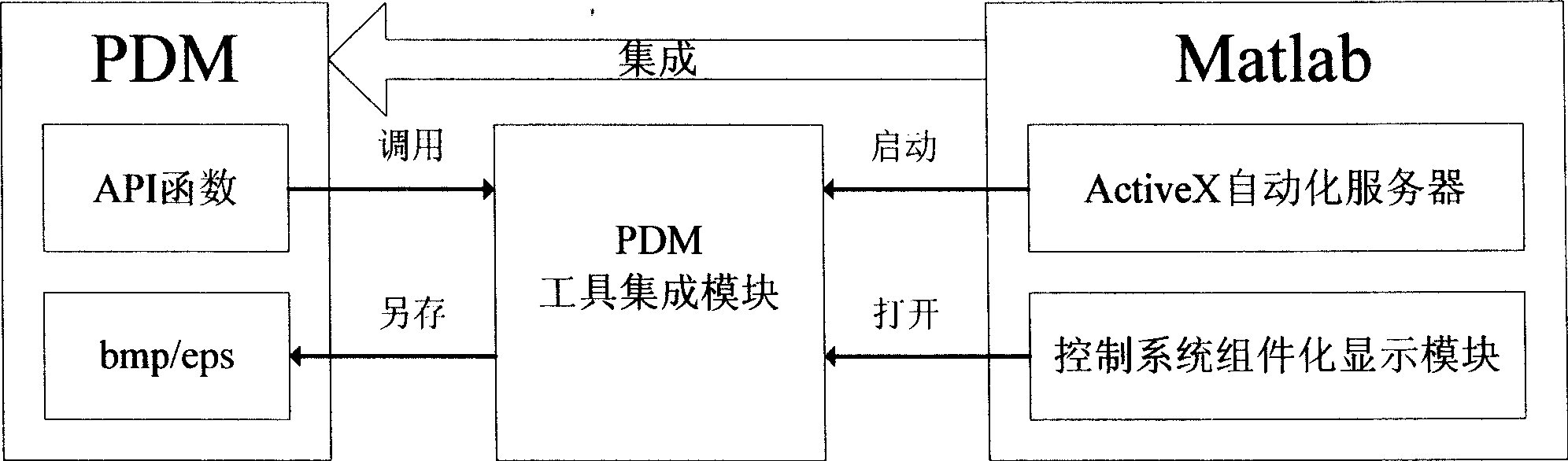

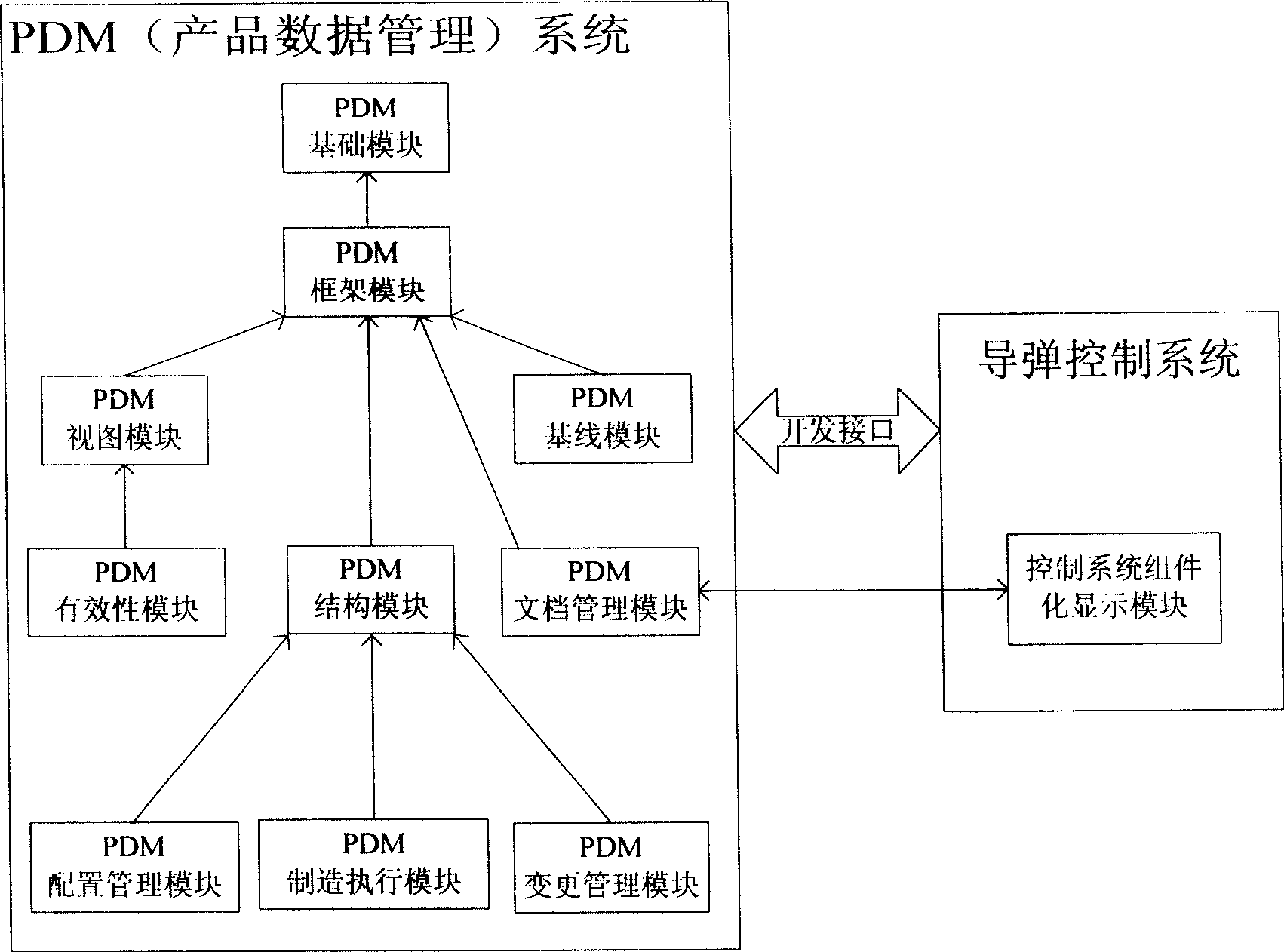

[0024] In the process of missil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com