Horizontal helix solid-liquid mixing apparatus

A spiral solid-liquid and mixing device technology, which is applied to mixers, mixing methods, mixers with rotating stirring devices, etc., can solve problems such as increased pressure, material supply and flow resistance of mixed materials, and achieve fast mixing speed, High mixing efficiency and uniform mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing.

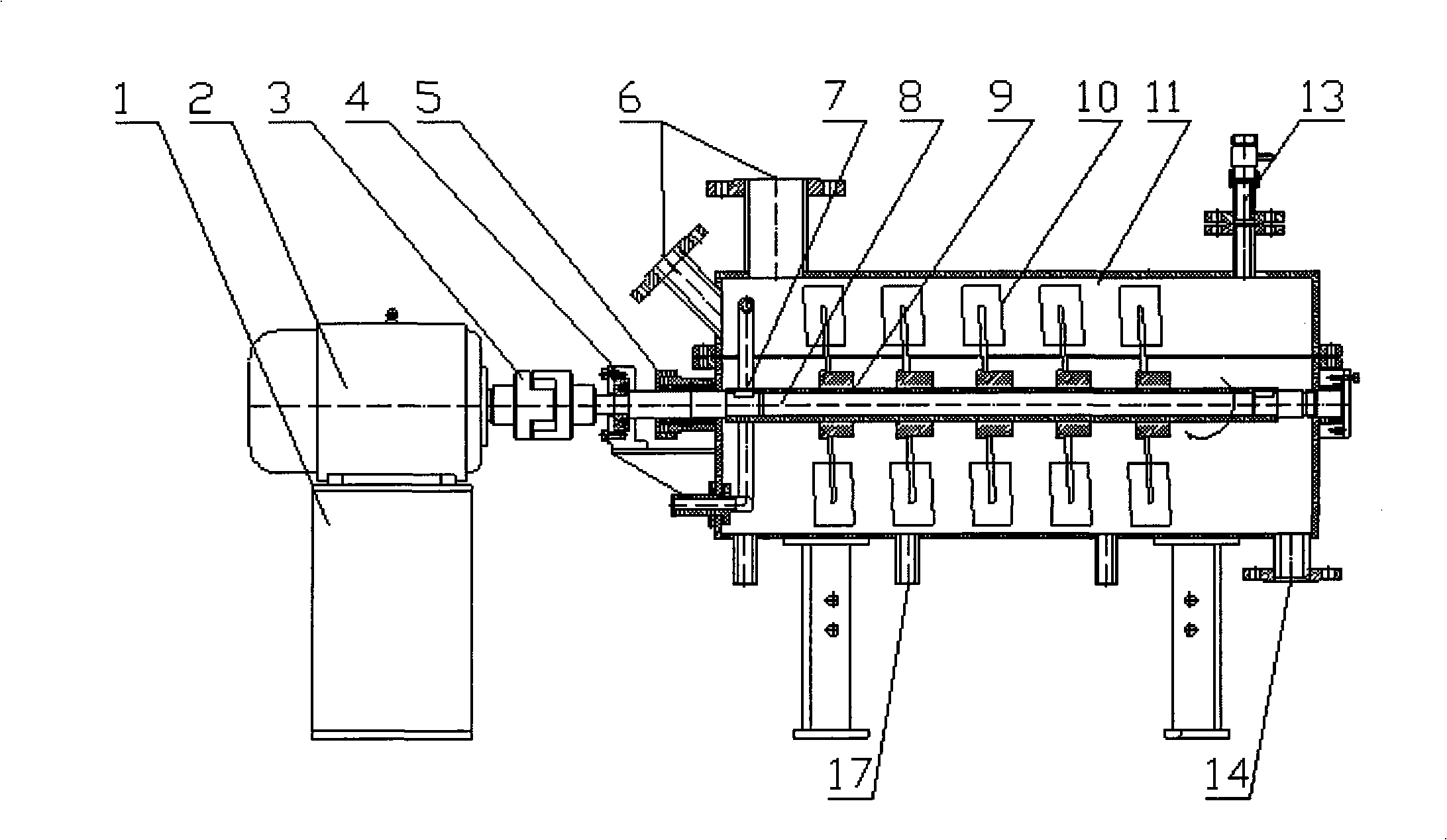

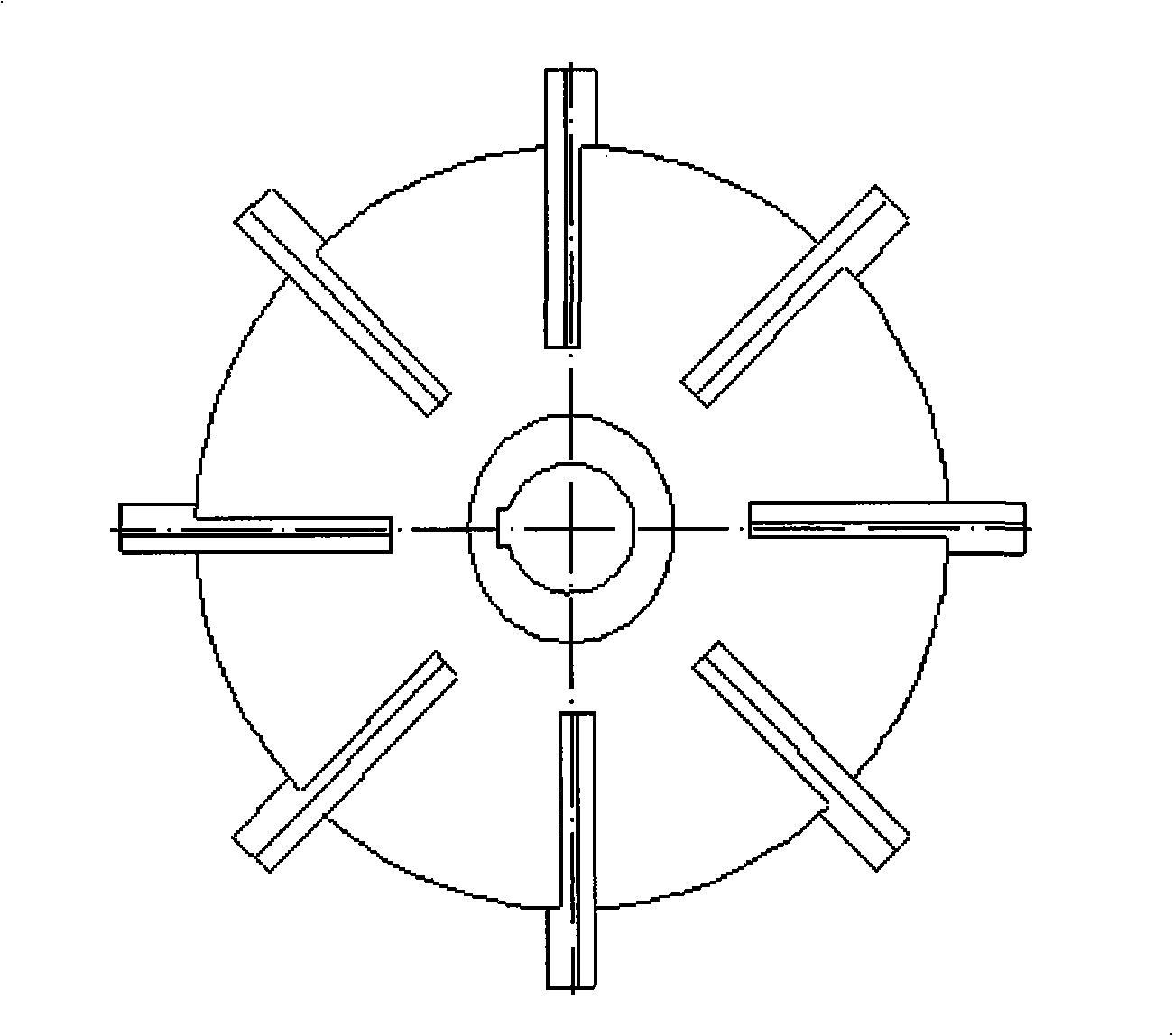

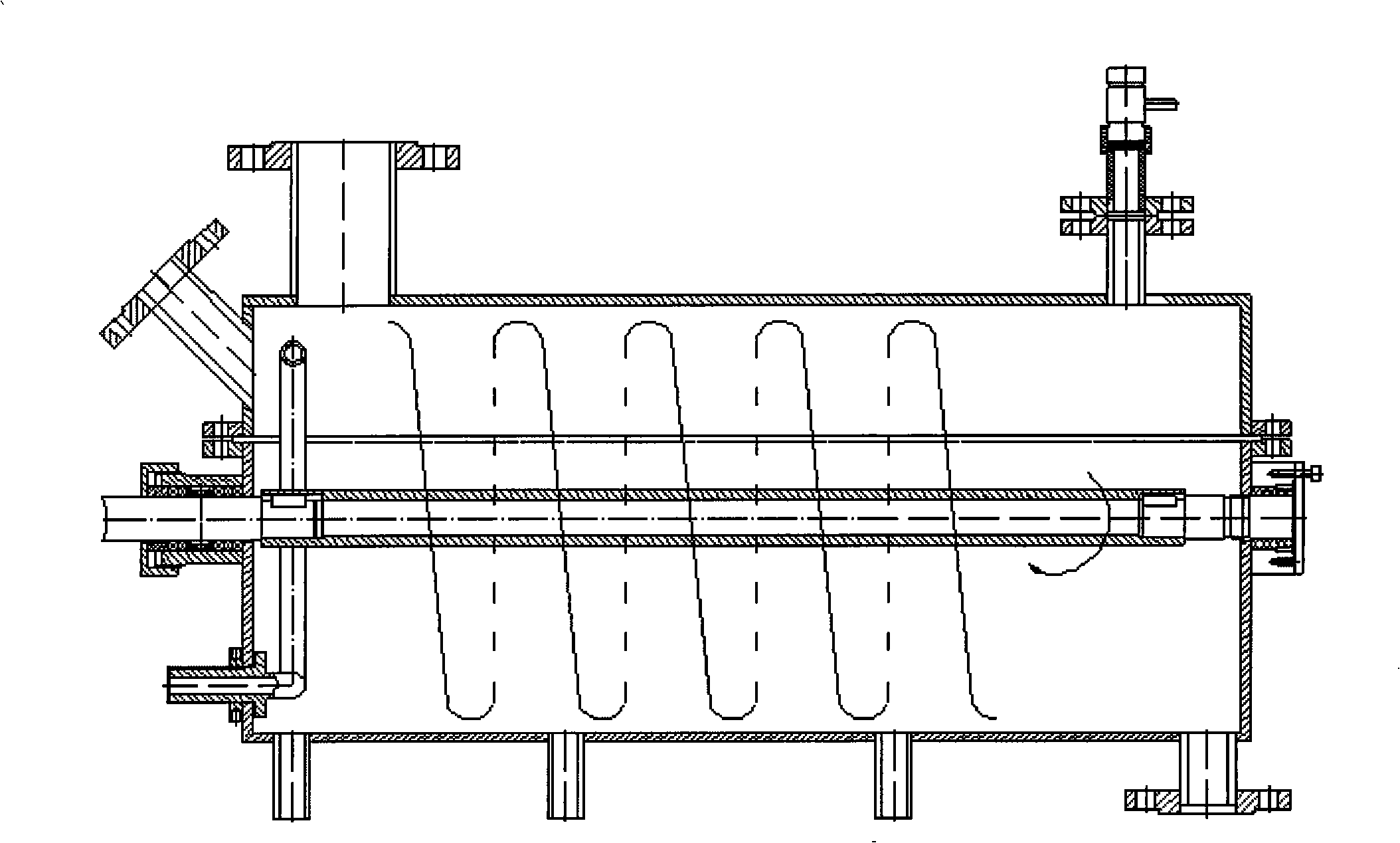

[0017] refer to figure 1 , The horizontal spiral solid-liquid mixing device includes a speed-regulating motor 2, a bearing seat 4, a cylindrical mixing chamber 11, the feeding end of the mixing chamber is provided with a solid feeding port 6 and a liquid feeding port 7, and the stirring and mixing chamber The discharge end is provided with a discharge port 14 and an exhaust port 13, the bottom of the mixing chamber 11 is provided with a cleaning port 17, and the center of the cylinder is provided with a stirring shaft 9, and the two ends of the stirring shaft 9 pass through the rotating shaft 8 and the bearing seat 4 respectively. Connection, the rotating shaft 8 extends out of the mixing chamber 11 and seals it through the stuffing box 5. In the illustration, five helical pitched blade turbine paddles 10 are fixed on the stirring shaft 9, which can be easily disassembled. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com