Deep draw mould without flange edge die plate

A technology without flange and die, applied in the field of deep drawing dies, can solve the problems of reducing tensile stress, high cost, limited use occasions, etc., to improve the ultimate deep drawing height, improve forming performance, reduce manufacturing costs and energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

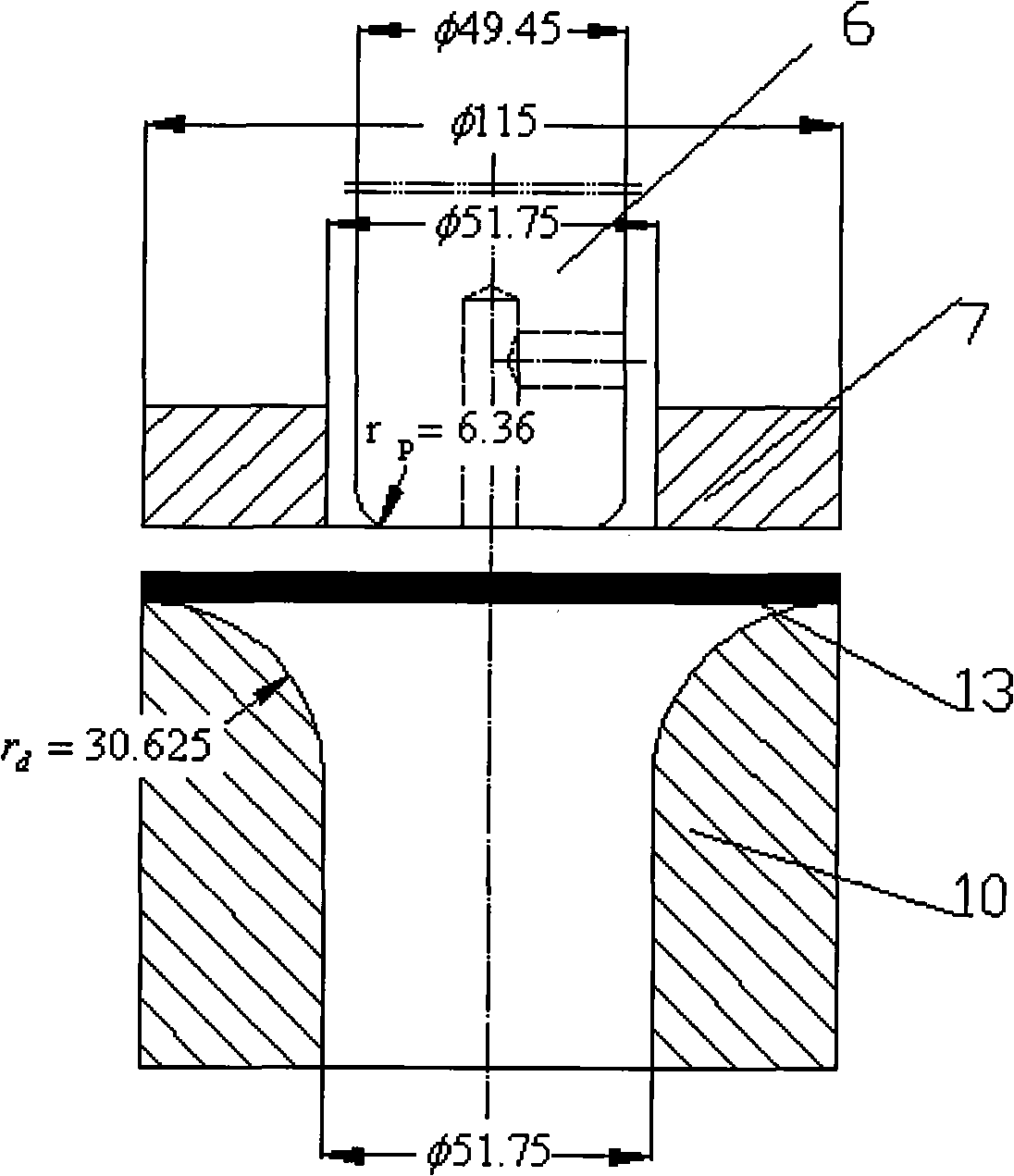

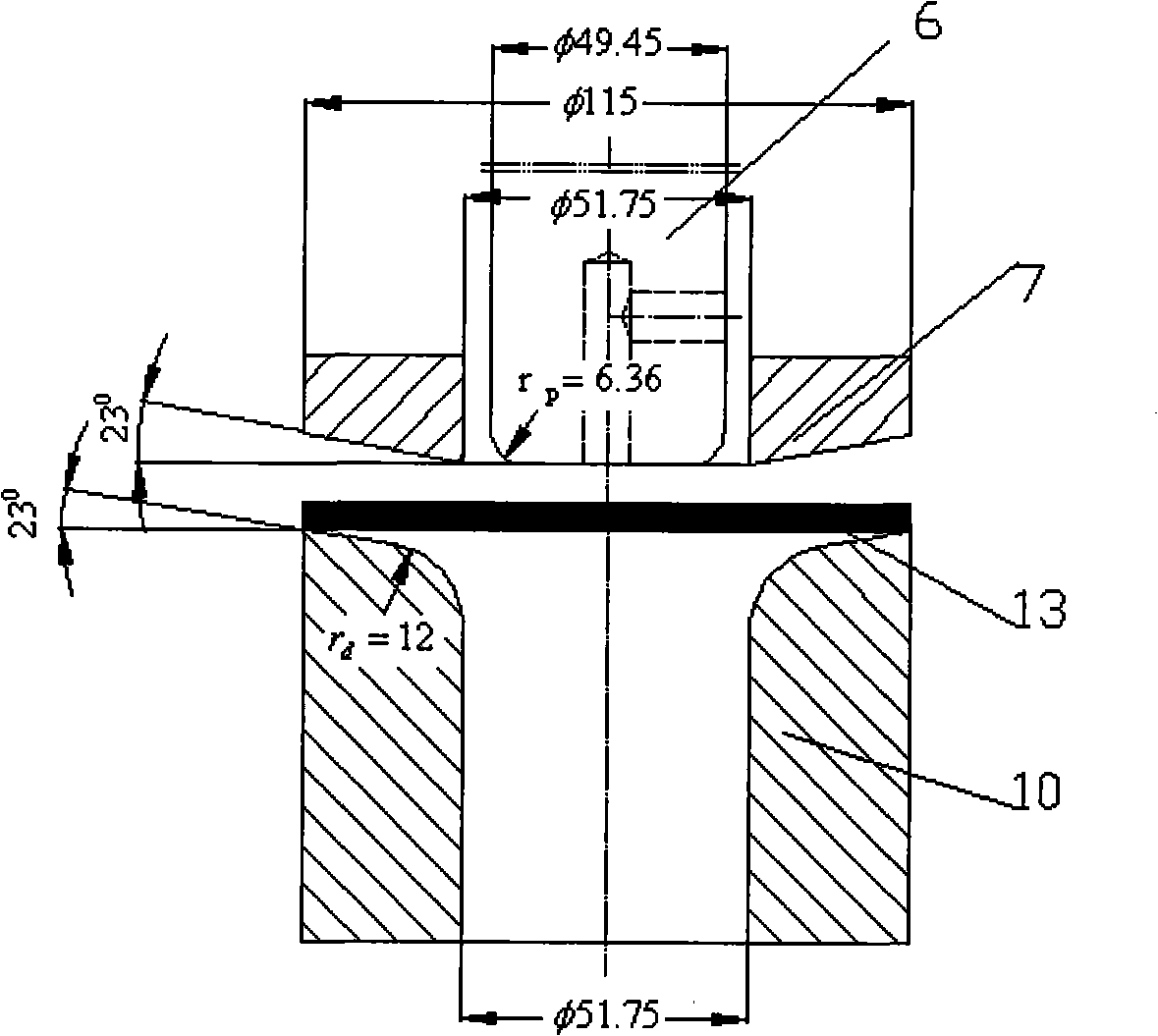

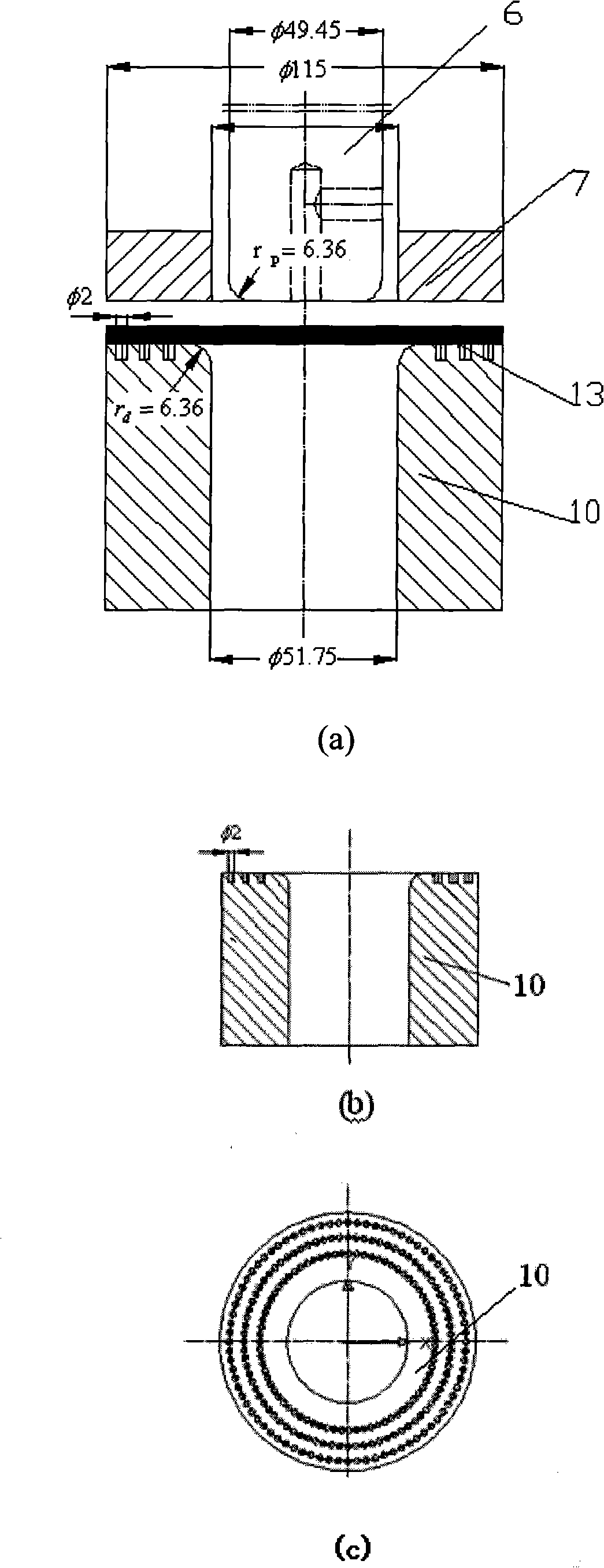

[0034] On the basis of the structure characteristics of the existing dies, a deep drawing die without a flanged die is proposed. The shape and size of the die of this kind of mold are consistent with the expanded shape and size of the drawn part, and the radius of the fillet of the die is equal to the radial length from the edge of the die to the cavity and transitions along the circumference. This mold structure has the following characteristics: (1) During deep drawing, the time for the rigid blank holder to act on the outer edge of the blank is relatively short, but since it is pressed on the arc surface at the beginning, and the arc surface is lowered radially Therefore, the thickening of the sheet metal will not exceed the initial plane of the blank. When the initial blank holder force takes a large value, the outer edge of the blank will not be warped; (2) When the blank holder is completed, the blank will Therefore, the increase of radial tensile stress used to overcome...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com