Process for producing fire resistant alpha-diastase

A production process, amylase technology, applied in the field of bioengineering enzyme preparations, can solve the problems of high production cost, simultaneous optimization of medium and fermentation process, blindness of technical guidance, etc., and achieve the effect of solving poor temperature resistance

Inactive Publication Date: 2010-12-01

张新武

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

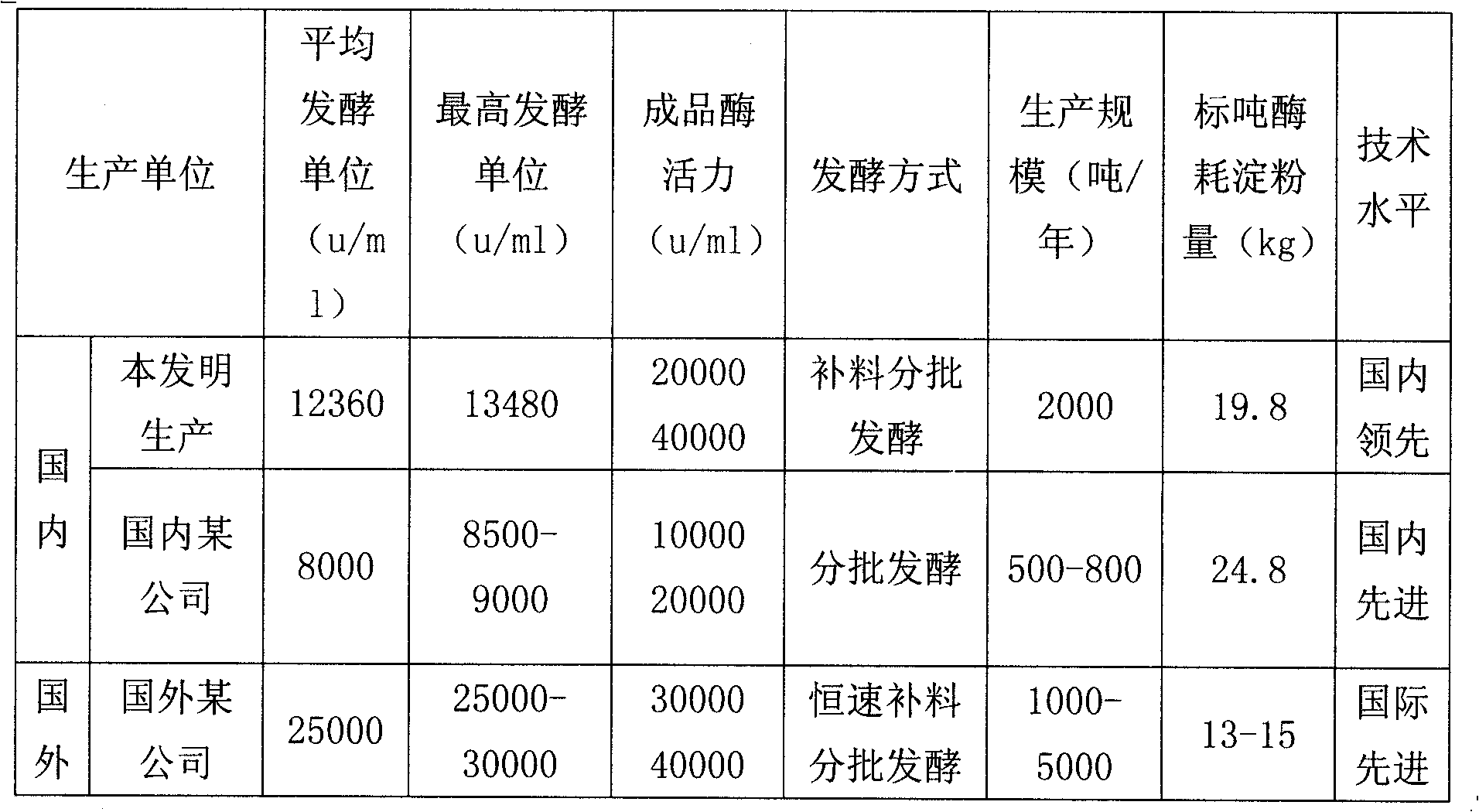

It was not until 1989 that foreign strains were introduced for industrial production. After more than ten years of hard work, the fermentation activity has increased from less than 500u / m1 to 8000u / m1, and individual manufacturers have reached 8500-9000u / m1, but this is different from the United States, Denmark and other countries. Compared with the high temperature resistant α-amylase fermentation level of 25000u / ml, there is still a big gap

Lin Jian, Cui Jingchun, etc. (Journal of Wuxi University of Light Industry, July 2003, Volume 22) improved the fermentation activity by adjusting the culture medium formula or fermentation process, but did not optimize the medium and fermentation process at the same time (Food and Fermentation Industry, No. 33, Phase 7, Volume 33, 2007) optimized the fermentation medium and process by shaking flask experiments, and verified it in a 50L fully automatic fermenter , the fermentation activity increased by 14%, reaching 14900u / ml, without carrying out larger pilot and industrial trial production

And Chinese patent 2007100361599 has reported a kind of high-activity, high-purity high-temperature-resistant α-amylase production process, adopts secondary fermentation, base material is fed feed, pulse feeds ammonia, uses the technology of cooked soybean meal as nitrogen source, adopts the technology of controlling fermentation temperature Fermentation at 43°C, pH 6.8, high temperature resistant α-amylase product is obtained through flocculation, pressure filtration, circulating primary filtration, and fine filtration. The process is relatively complicated, which affects its large-scale promotion

At present, in the process of industrialized production of high-temperature-resistant α-amylase, due to the lack of systematic theoretical basis, manufacturers mostly guide production based on production experience, production management and technical guidance are blind, and high-temperature-resistant α-amylase belongs to the middle Non-toxic fermentation environment, the success rate of fermentation is not high, resulting in high production costs and weak market competitiveness

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

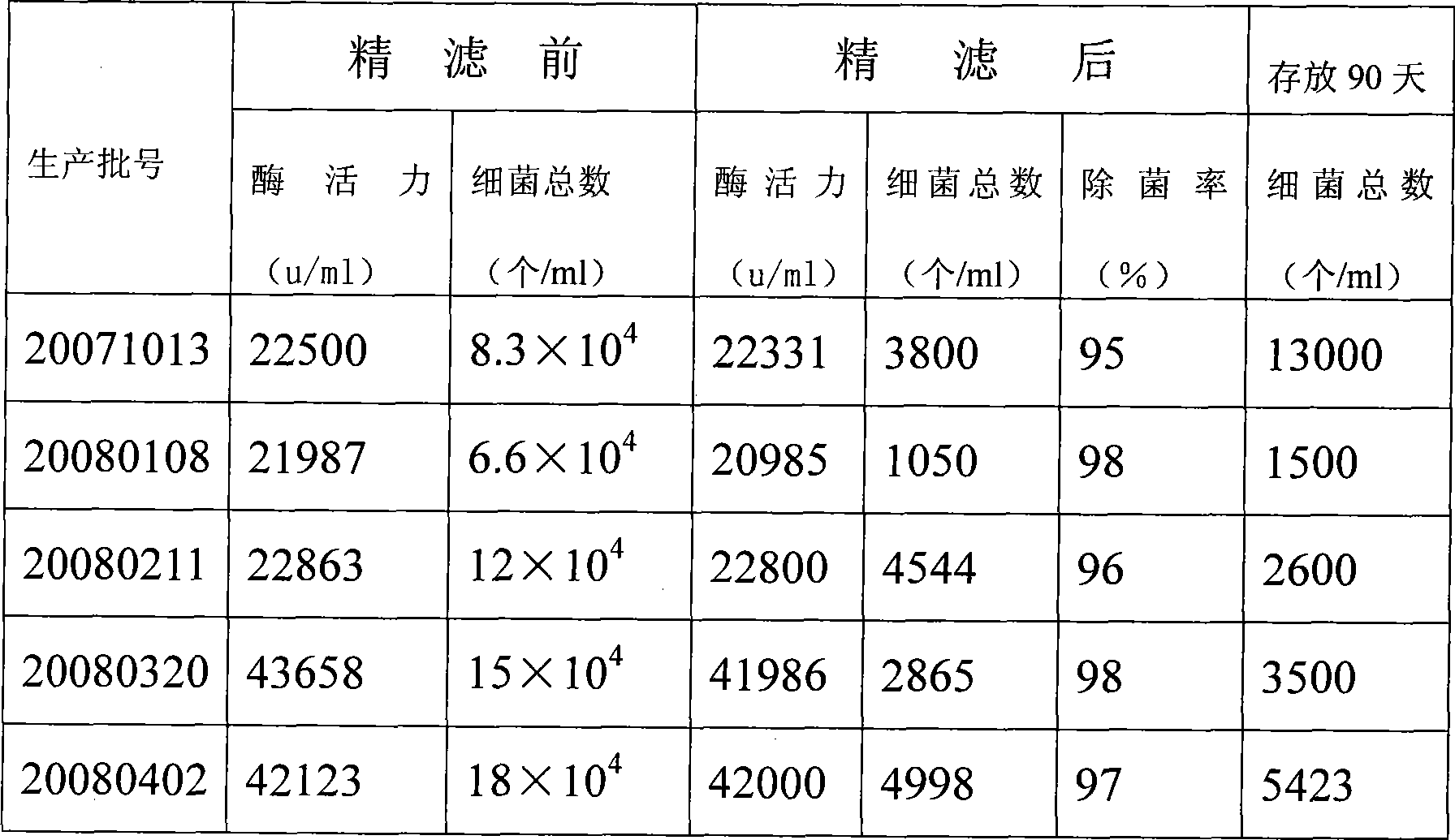

The invention discloses a preparation method of thermostable Alpha-amylase, pertaining to the technical field of bioengineering enzyme preparation. The preparation method uses bacillus licheniformis as strains and corns as carbon and nitrogen sources to produce the Alpha-amylase of high temperature resistance and high activity by fermenting in a first-grade seed tank, batch fermenting with feeding in big tank, fine filtering and sterilizing process. The fermentation capacity can reach a top of 13480u / ml, with an average level of enzymatic production with fermentation of 12360u / ml. The capacity is 54.5 percent higher than the fermenting level which is 7982u / ml before the prior art is optimized. Every standard ton of enzyme consumes 19.8kg of starch, being 5kg less than the batch fermentingwhich consumes 24.8kg, thus forming a complete set of fermenting feeding batch technique of thermostable Alpha-amylase and realizing the industrial scale production of thermostable Alpha-amylase.

Description

High temperature resistant α-amylase production process technical field The invention relates to a production method of a bioengineering enzyme preparation, in particular to a production method of a high-temperature-resistant alpha-amylase. Background technique As a new type of enzyme preparation, high temperature resistant α-amylase has wide application and good market prospects in fermentation and grain deep processing industries. It is currently widely used in alcohol, beer, monosodium glutamate, organic acid, starch sugar and pharmaceutical industries. And sales are increasing year by year. Since the 1980s, my country has started research on the production technology of high-temperature-resistant α-amylase. The Shanghai Institute of Industrial Microbiology has used Bacillus licheniformis as the starting strain to increase the enzyme production unit from 1-2 units / ml to 100 units / ml. about milliliters. It was not until 1989 that foreign strains were introduced for indu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C12N9/28C12R1/10

Inventor 杜保安张新武崔跃远

Owner 张新武

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com