Gas-liquid two-phase separation type gravity assisted heat pipe solar boiler

A gravity heat pipe and phase separation technology, which is applied in the field of solar boilers, can solve problems such as complex system structure, distortion of evaporation tubes, and large temperature differences, and achieve the effect of simple and reliable system, less maintenance, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

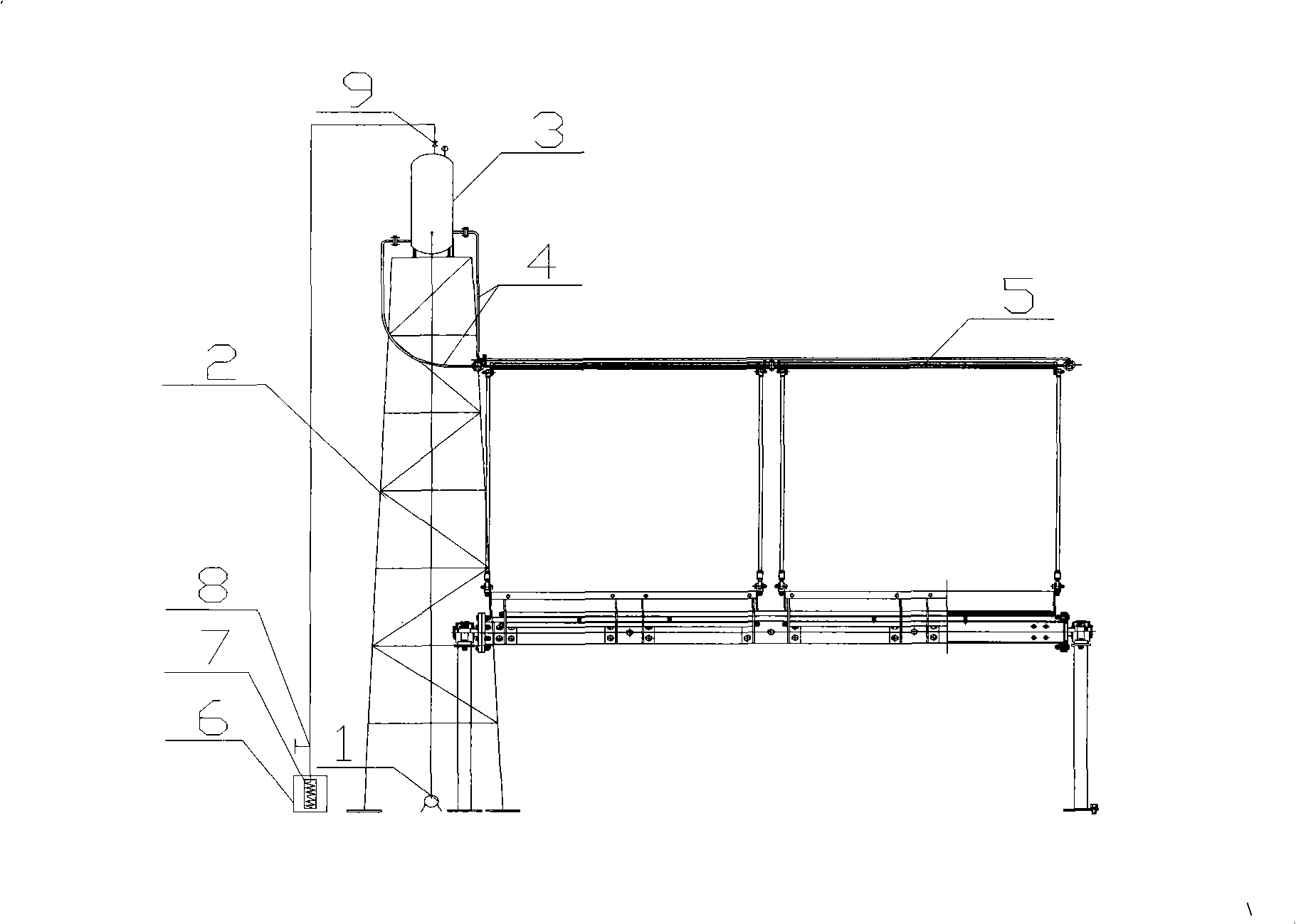

[0014] Such as figure 1 As shown, the vapor-liquid two-phase separation type gravity heat pipe solar boiler includes a water pump 1, a first bracket 2, a drum 3, a metal hose 4, a heat pipe solar evaporator 5, a bucket 6, a condenser 7, a control valve 8, a single To valve 9, solar concentrator, the upper end of the first bracket 2 is provided with a drum 3, the drum 3 is connected to the heat pipe solar evaporator 5 through a metal hose 4, and the drum 3 is controlled by a one-way valve 9 The valve 8 is connected with the condenser 7, the condenser 7 is arranged in the water bucket 6, the water pump 1 is connected with the drum 3, and the solar concentrator is arranged at the corresponding position of the heat pipe type solar evaporator 5.

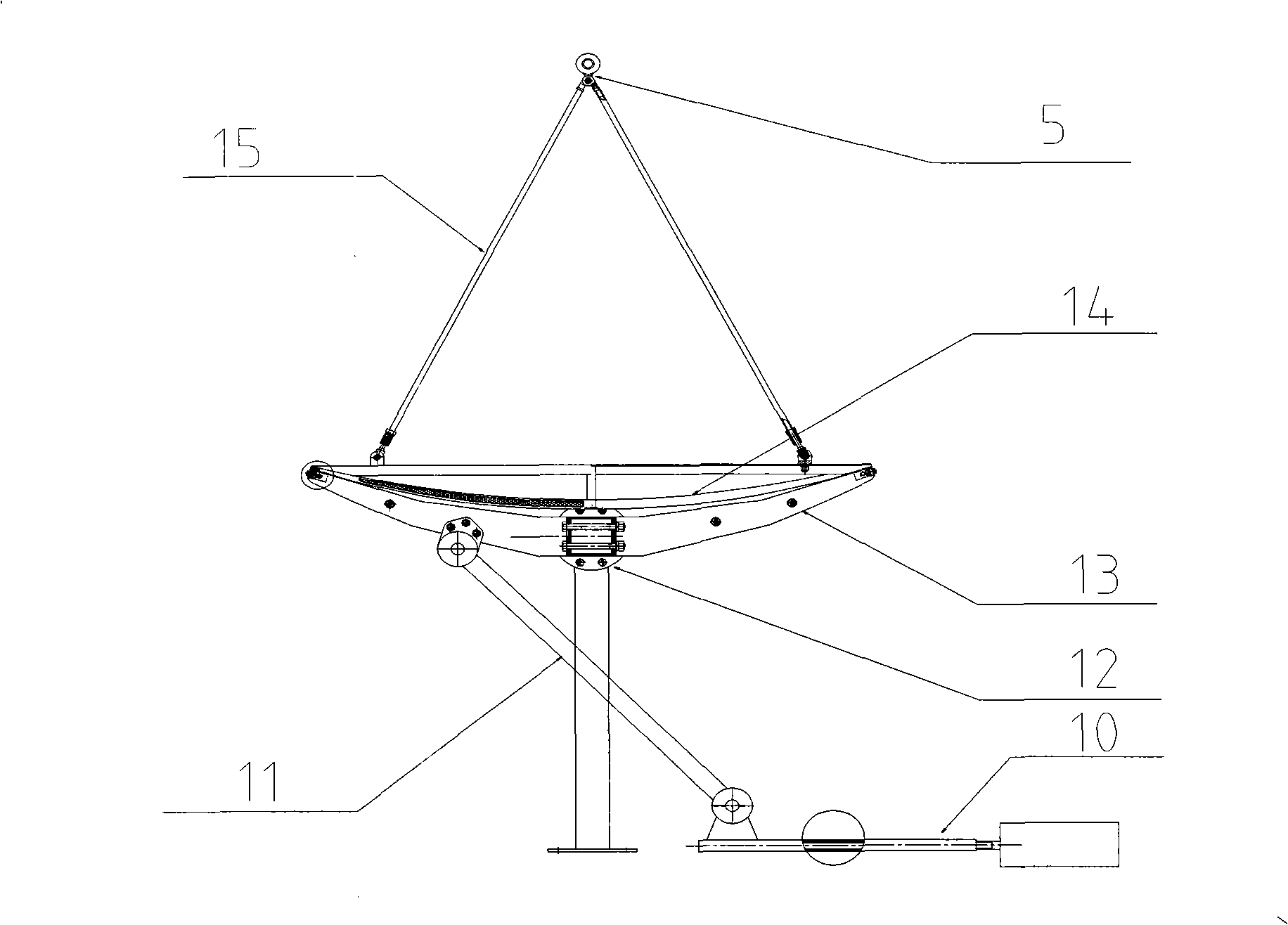

[0015] Such as figure 2 As shown, the solar concentrator includes a hydraulic driving device 10, a transmission connecting rod 11, a rotating shaft 12, a mirror fixing bracket 13, a glass reflecting mirror 14, and a heat collecting tube fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com