Vacuum circuit breaker

A technology of vacuum circuit breakers and vacuum tubes, which is applied in the direction of high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of pollution resistance level only up to level III, high failure rate of circuit breakers, insulation breakdown, etc., and achieve reduction in quantity and The possibility of air leakage, the effect of improving the insulation level, and enhancing the pollution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

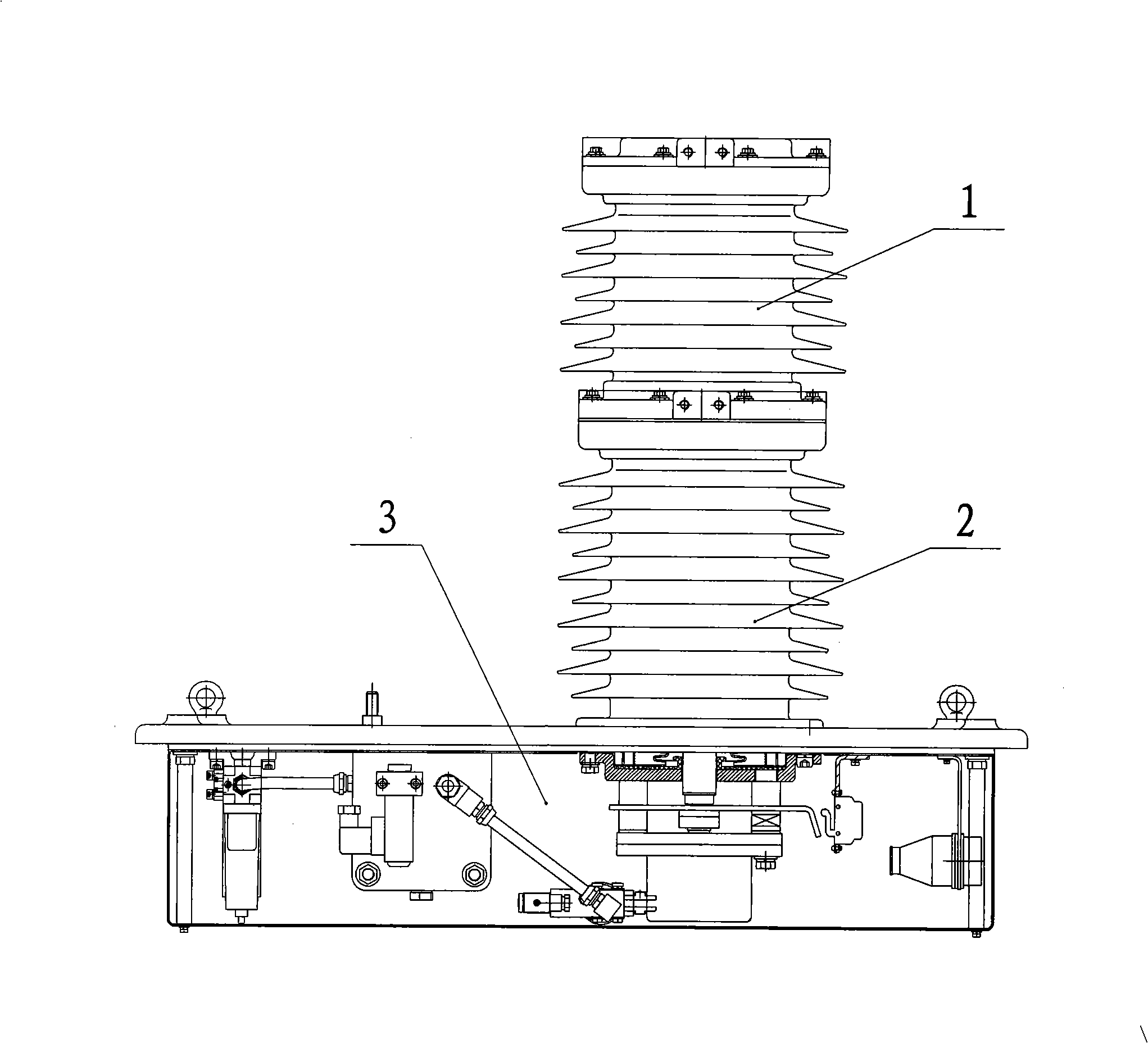

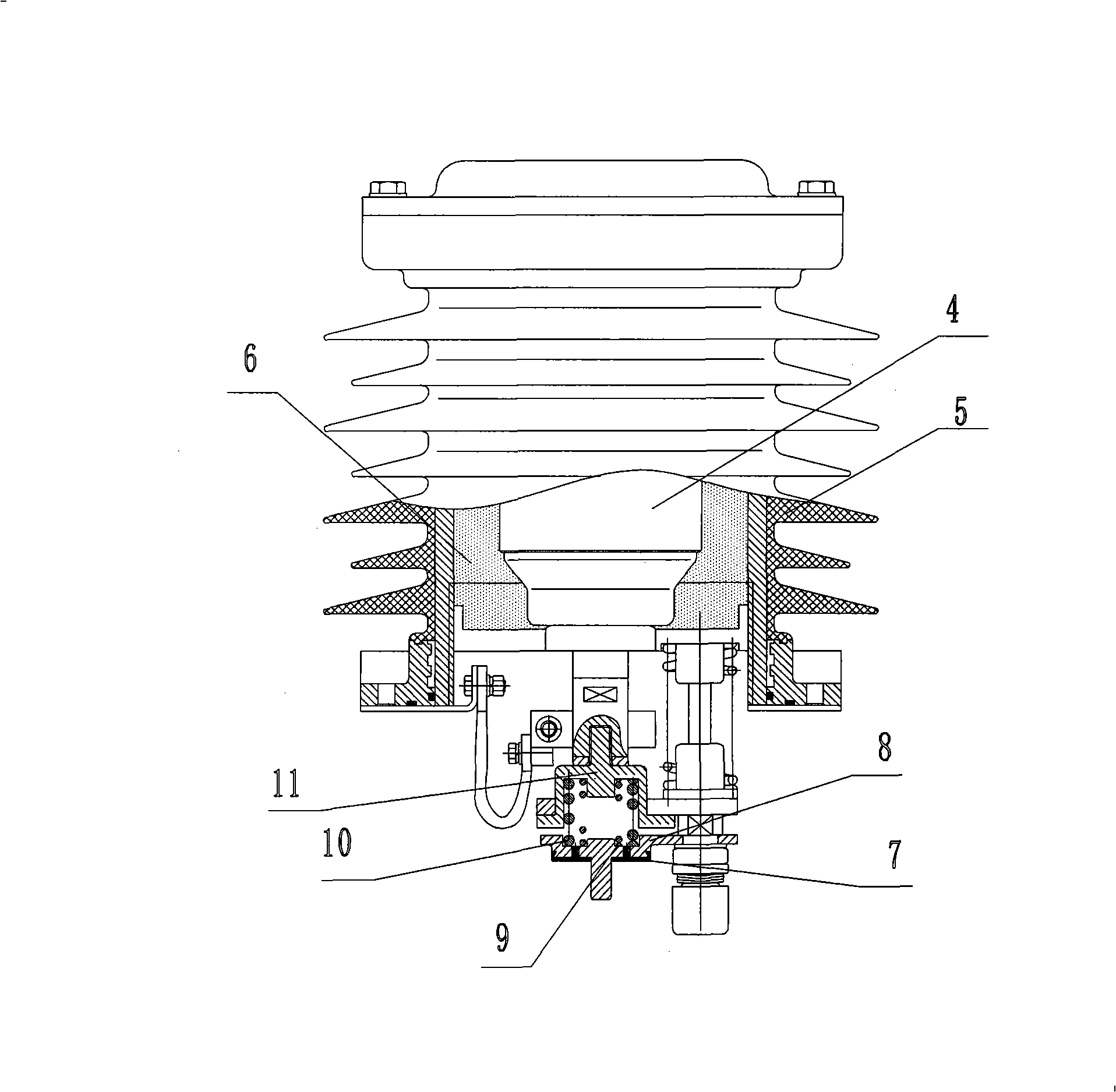

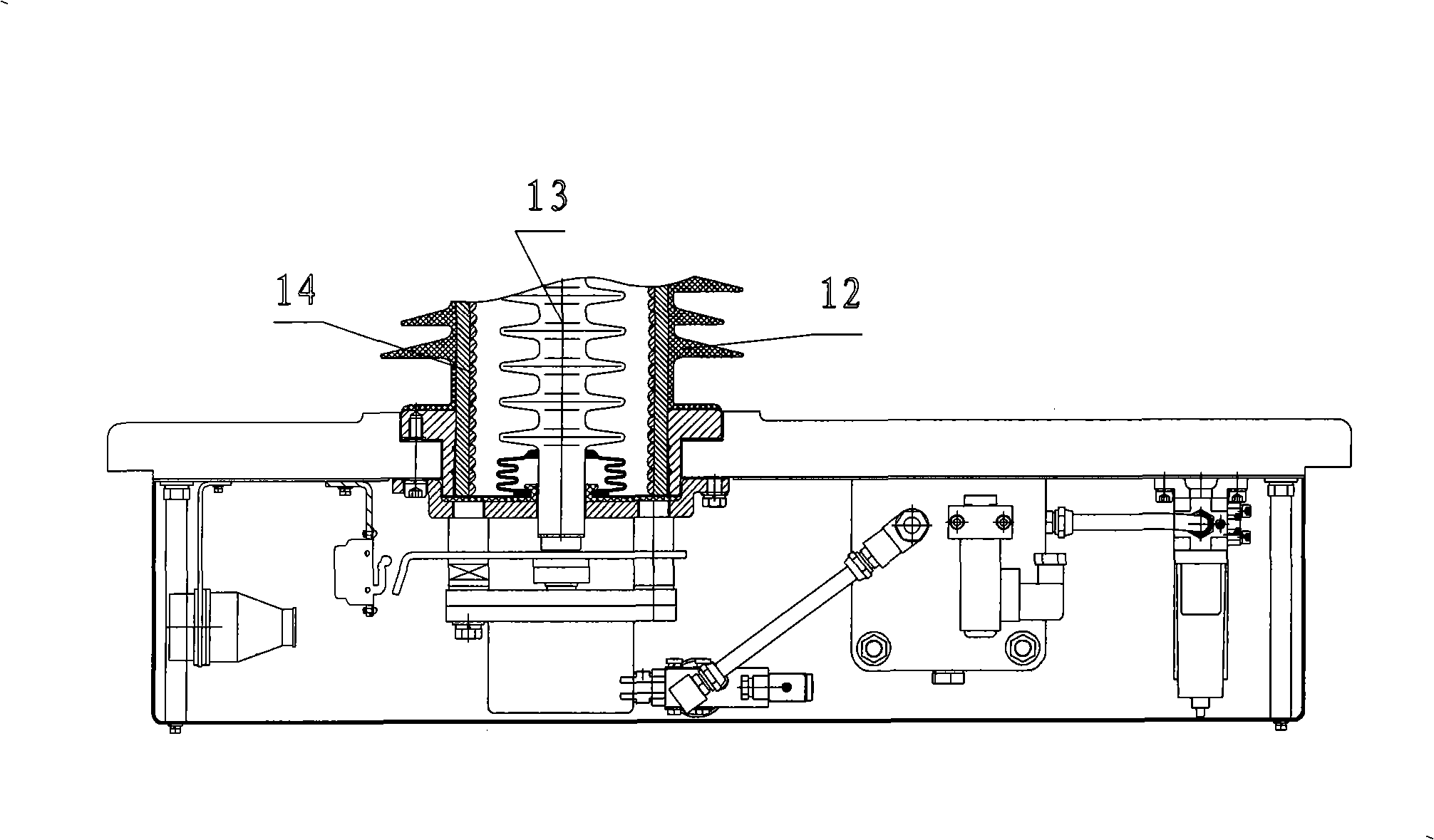

[0043] A vertical cylindrical vacuum circuit breaker, such as Figure 1 to Figure 4As shown, it is composed of a high-voltage component 1, an insulating support component 2, and a low-voltage control component 3 which are sequentially stacked from top to bottom. The upper and lower ends of the vacuum tube 4 are respectively provided with static and movable contacts. The lower end of the movable contact is provided with a spring mechanism that keeps the dynamic and static contacts in a normal state. The spring mechanism is an integrated three-column spring mechanism. It consists of a closing spring 10 and a spring. Composed of an opposing pressure plate assembly 7, a cylindrical cavity containing the closing spring and a connecting seat 11 connected with the moving contact, and a spring cover 8 matched with the connecting seat. The pressure plate assembly 7, the spring cover 8 and the closing spring 10 Coaxial installation, the connecting seat is provided with a boss coaxial with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com