Protective film and method of processing the same

A processing method and technology of protective film, which are applied in the directions of pollution prevention methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of peeling off of protective film, inability to eliminate pores, failure to fully overlap, etc., and achieve a few steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

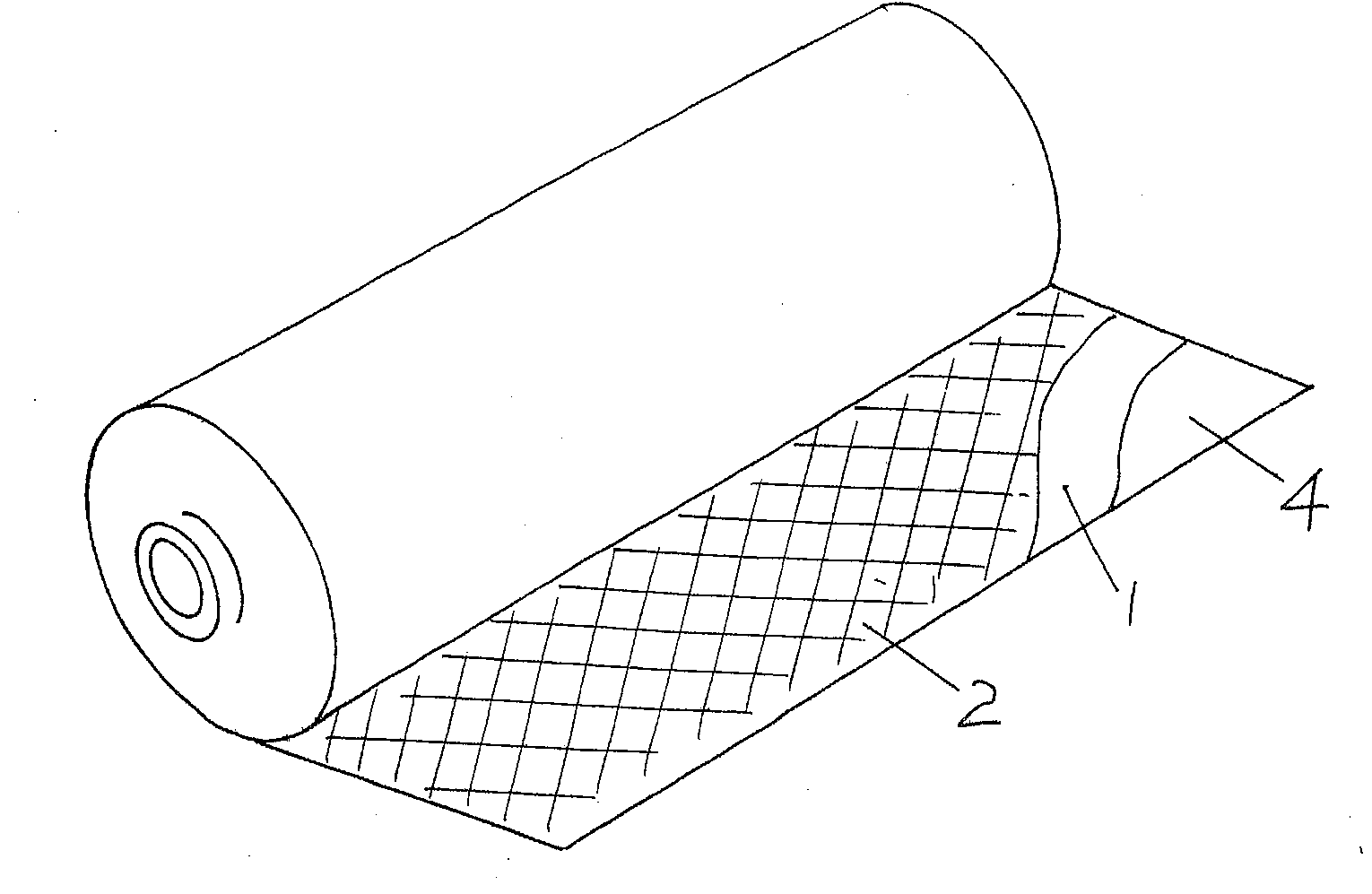

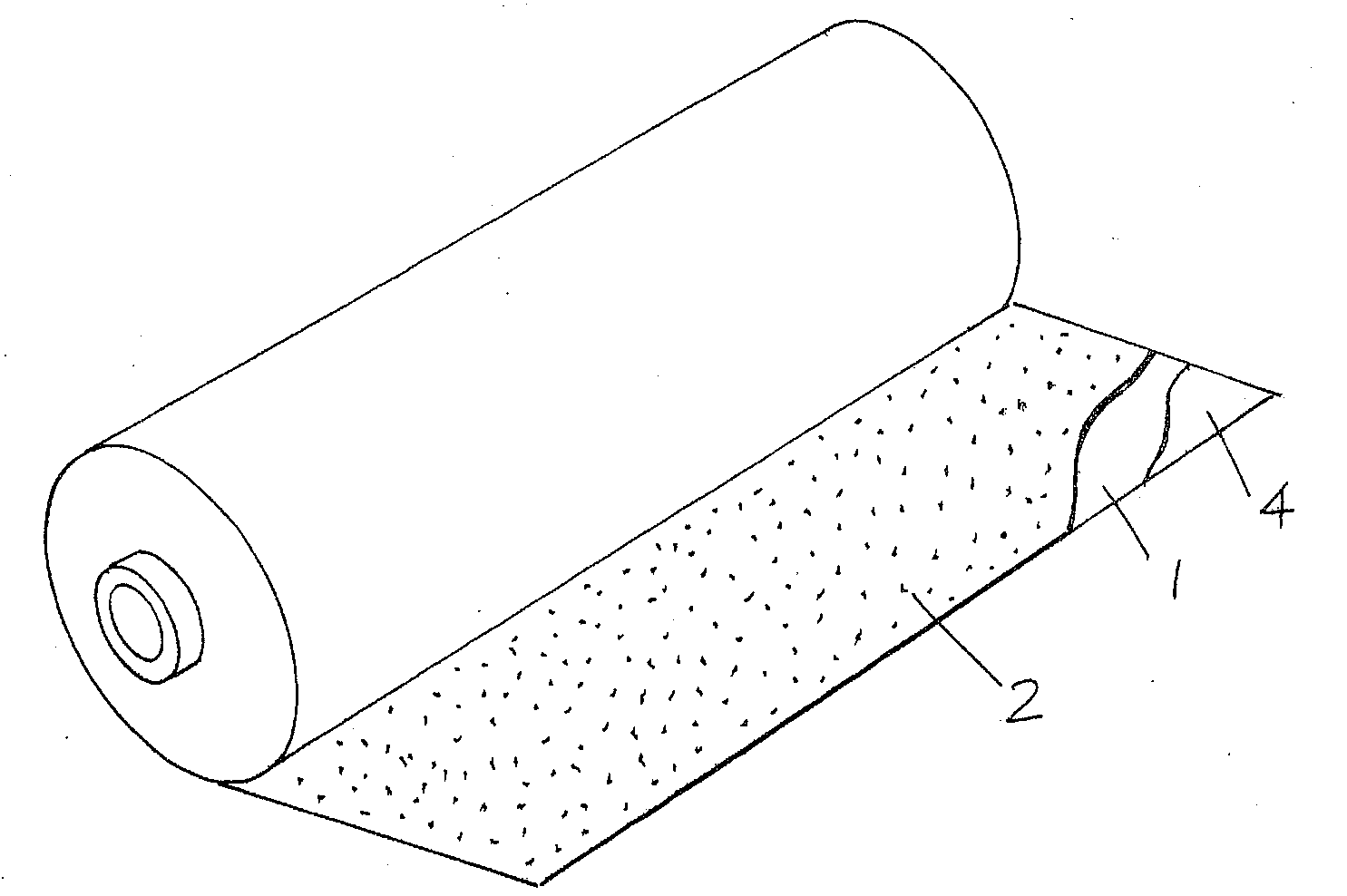

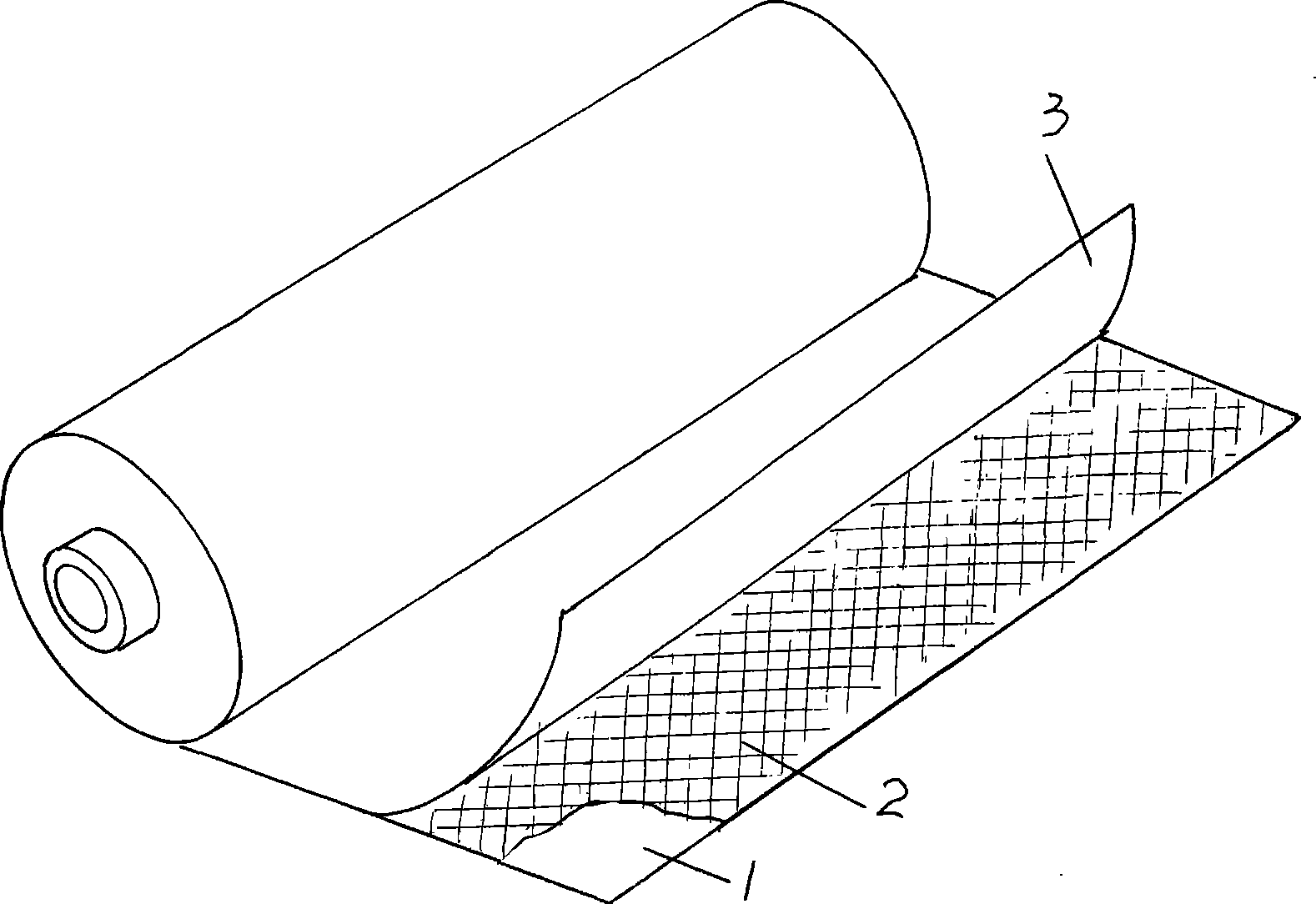

[0029] please see figure 1 .

[0030] A) Select a qualified substrate 1, specifically select a polyester film with no pinholes, no crystal points, no scratch damage, no wrinkles, good transparency and smoothness as the substrate 1, and the thickness of the substrate 1 is 75 μm;

[0031] B) Coating, before coating, corona treatment is carried out to the surface of the substrate 1, and the oily acrylic is coated on one side surface of the substrate 1 with the glue roller of the coating machine, wherein: the coating The surface of the gluing roller of the cloth machine is formed (processed) with an anilox structure, that is, an anilox roller or a grid-like gluing roller is used. The mesh is 30 mesh, and the oily acrylic is The thickness on the substrate 1 is 12 μm, and the control of the thickness is obtained by adjusting the gap between the scraper and the glue roller. The oily acrylic acid is preferably but not limited to Kunshan Shimei Fine Chemical Co., Ltd. The product mo...

Embodiment 2

[0034] please see figure 1 .

[0035] A) Select a qualified substrate 1, specifically select a polyester film with no pinholes, no crystal points, no scratches, no wrinkles, good transparency and smoothness as the substrate 1, and the thickness of the substrate 1 is 8 μm;

[0036] B) Coating, before coating, corona treatment is carried out to the surface of the substrate 1, and the oily acrylic is coated on one side surface of the substrate 1 with the glue roller of the coating machine, wherein: the coating The surface of the gluing roller of the cloth machine is formed (processed) with an anilox structure, that is, an anilox roller or a grid-like gluing roller is used. The mesh is 300 mesh, and the oily acrylic The thickness on the substrate 1 is 2 μm, and the control of the thickness is obtained by adjusting the gap between the scraper and the glue roller. The oily acrylic acid is preferably but not limited to Kunshan Shimei Fine Chemical Co., Ltd. The product model produ...

Embodiment 3

[0039] please see figure 1 .

[0040] A) Select a qualified substrate 1, specifically select a polyester film with no pinholes, no crystal points, no scratches, no wrinkles, good transparency and smoothness as the substrate 1, and the thickness of the substrate 1 is 100 μm;

[0041]B) Coating, before coating, corona treatment is carried out to the surface of substrate 1 earlier, water-based acrylic is coated on one side surface of substrate 1 with the glue roller of coating machine, wherein: described coating The surface of the gluing roller of the cloth machine has (processed) a network-like structure, that is, an anilox roller or a gluing roller with a grid-like surface. The mesh is 80 mesh, and the water-based acrylic The thickness on the base material 1 is 15 μm, and the control of the thickness is obtained by adjusting the gap between the scraper and the glue roller. The product model produced and sold by Chemical Co., Ltd. is water-based 701-11 acrylic acid. Through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com