Method and device for operating open-end spinning machine

A technology of rotor spinning and free end, which is applied in the direction of free end spinning machine, spinning machine, continuous winding spinning machine, etc., can solve the problems such as putting forward excessive requirements, reduce the burden, reduce the rate of strain, reduce the burden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

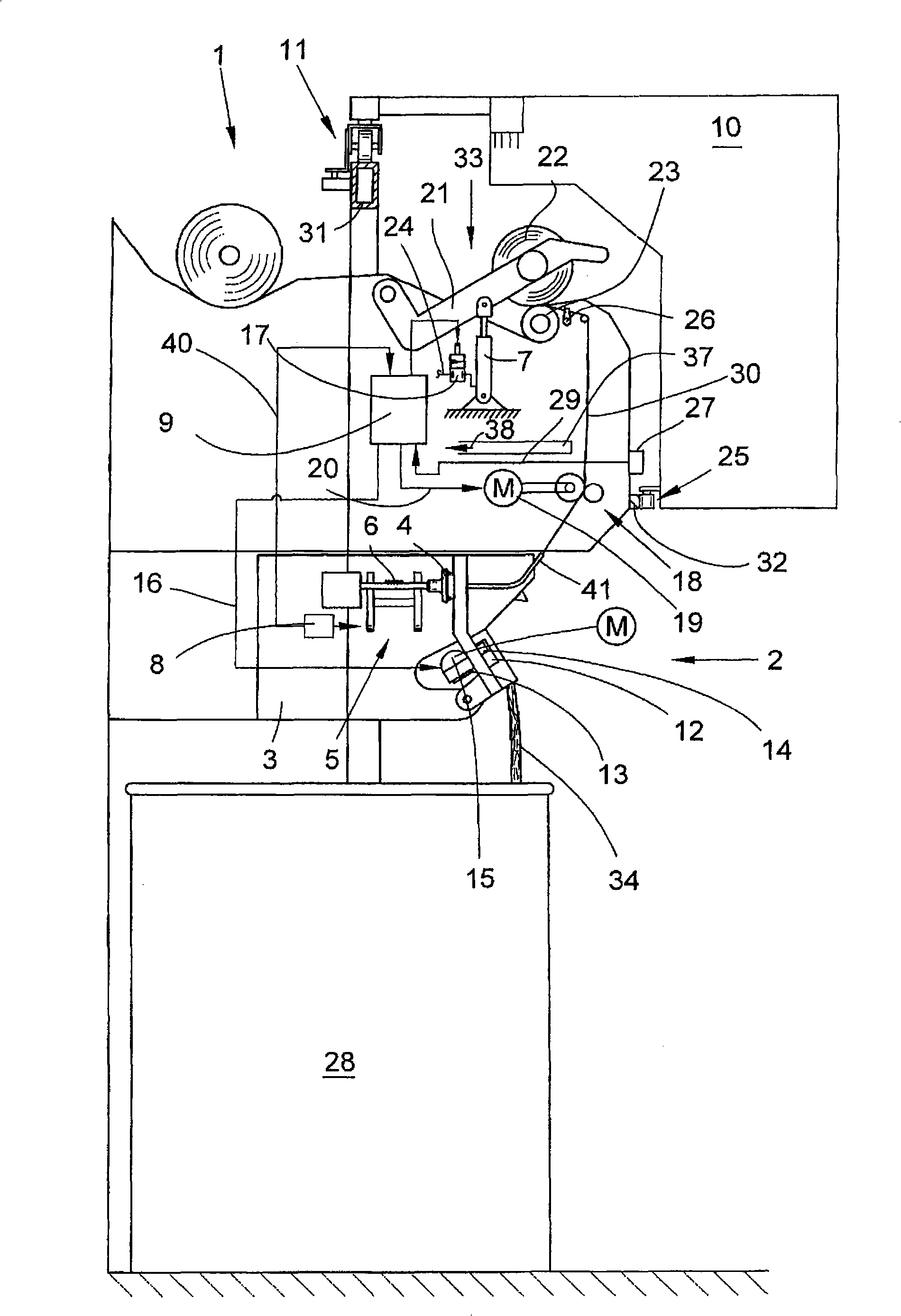

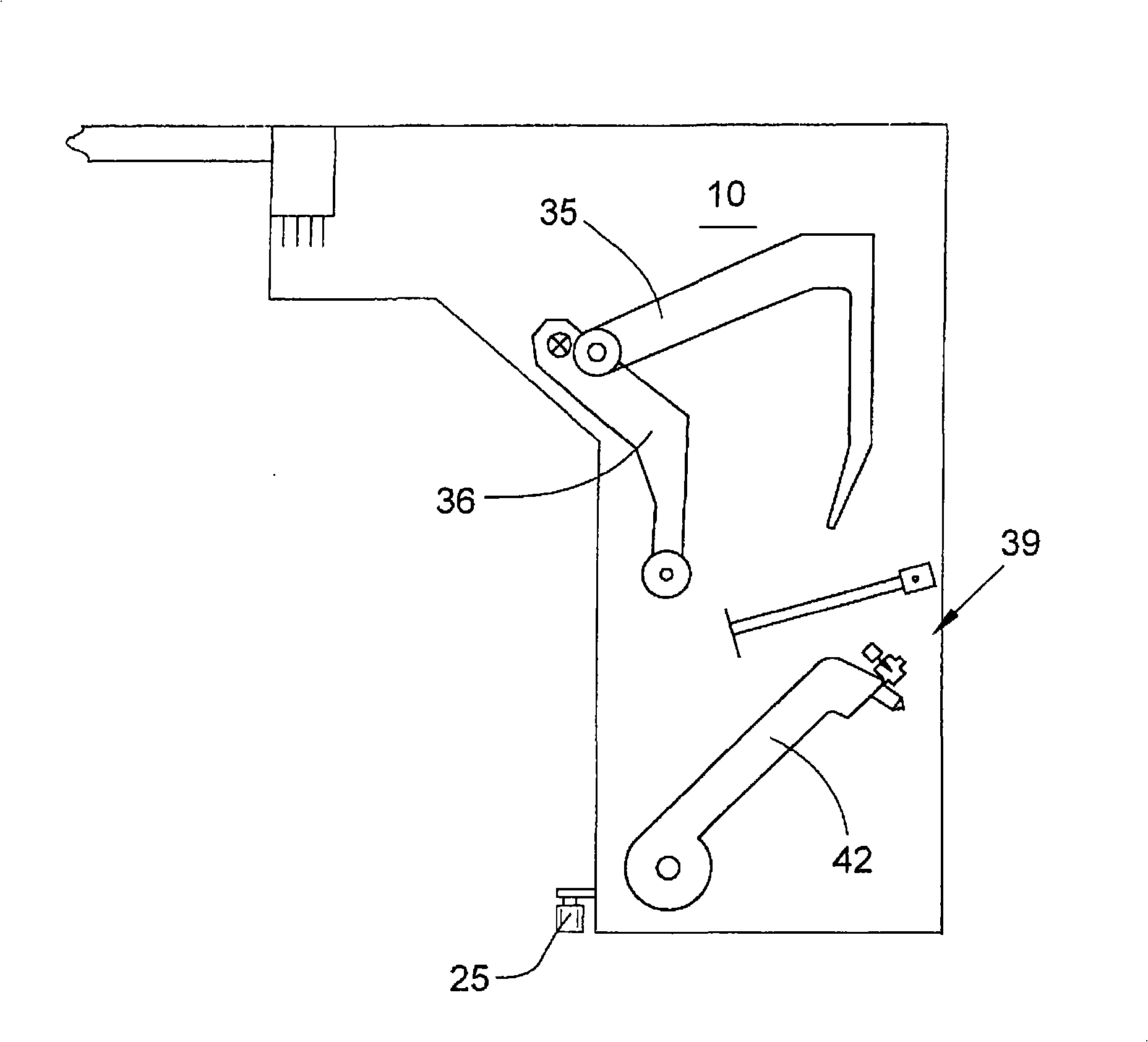

[0023] figure 1 One half of an open-end rotor spinning machine 1 according to the invention is shown. Such a spinning machine has a plurality of stations 2 which are each equipped with a spinning device 3 and a winding device 33 . The fiber ribbon 34 supplied in the spinning drum 28 is spun into yarns 30 in the spinning device 3 , and the yarns 30 are wound into a cross-wound bobbin 22 on a winding device 33 .

[0024] For this purpose, the winding device 33 has, as it is known per se, a creel 21 for rotatably holding a tube of a cross-wound bobbin 22; a bobbin drive roller 23; a yarn traversing mechanism 26 and A mechanism 7 for lifting the cross-wound bobbin 22 from the bobbin drive roller 23 . The mechanism 7 is designed, for example, as a thrust piston drive, which is connected to an excess pressure source (not shown) via a pneumatic line 24 into which the solenoid valve 17 is connected.

[0025] In this embodiment, the bobbin drive roller 23 is driven in the form of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com