Fabrication method of polymer resistive humidity sensor with hyperbranched structure

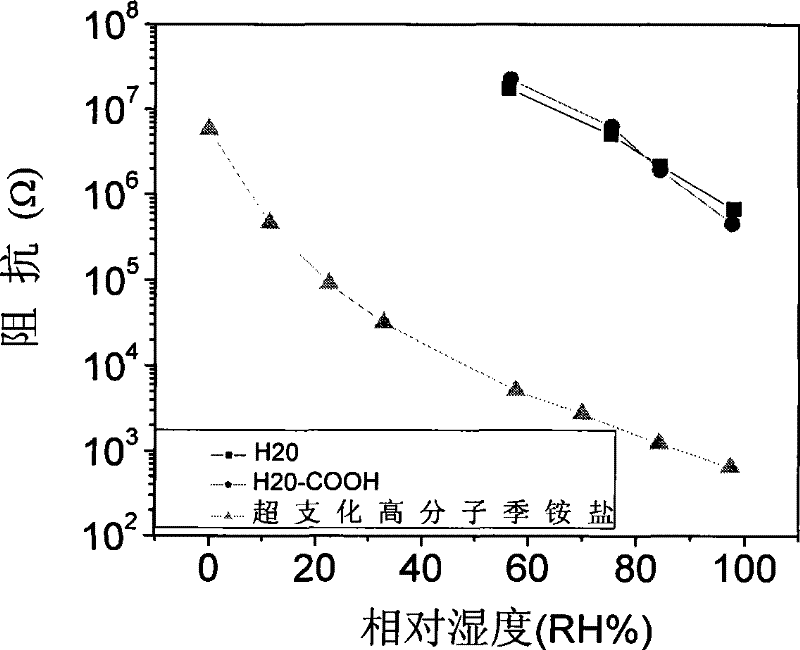

A technology of a humidity sensitive element and a manufacturing method, applied in the direction of material resistance, etc., can solve the problems of difficulty in measuring low-humidity environment, difficulty in measuring high resistance, difficulty in ion migration, etc., and achieve the advantages of cheap raw materials, improved contact, and improved ionic conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

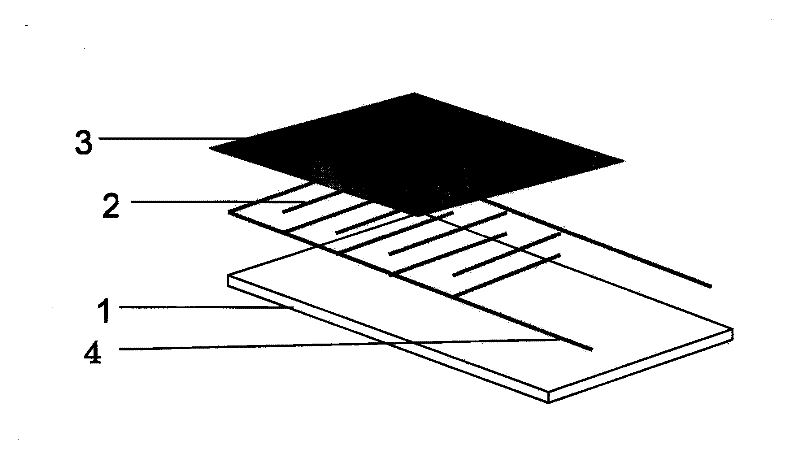

[0031] 1) cleaning the surface photolithography and evaporating the ceramic substrate with interdigitated gold electrodes, and drying for later use;

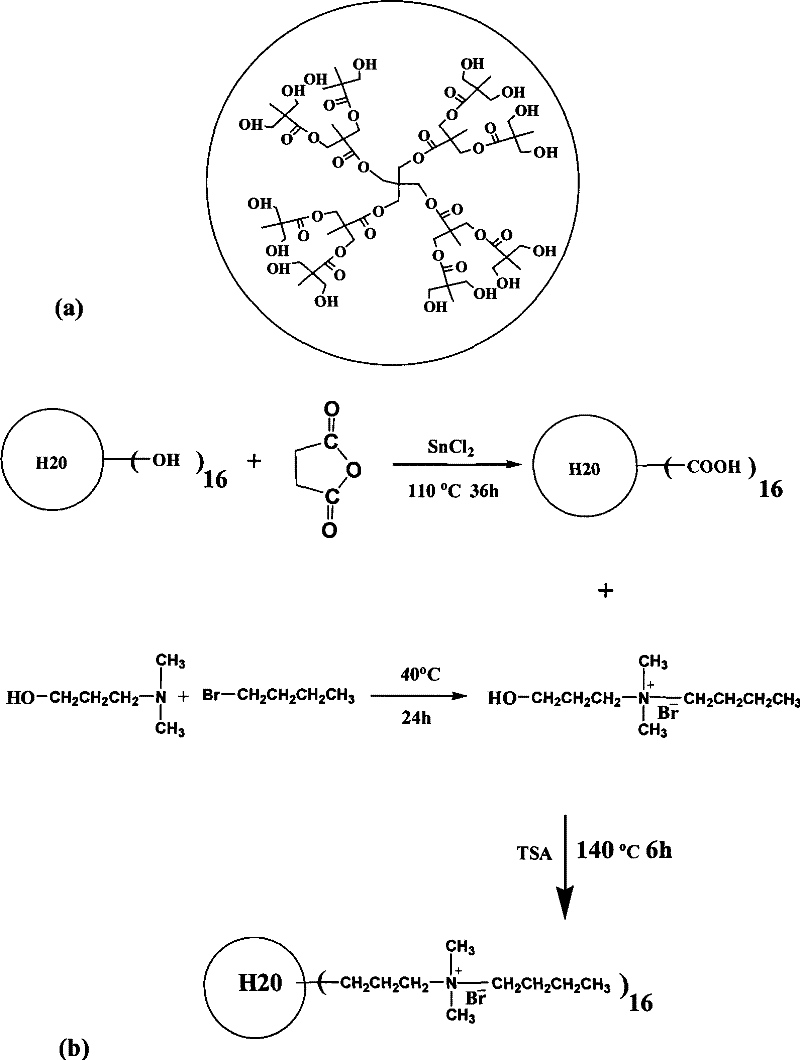

[0032] 2) In the 100 ml three-necked flask after dehydration and deoxygenation treatment, add 10 grams of hyperbranched compound H O with structure (I), 10 grams of succinic anhydride, 0.2 grams of SnCl 2 , 30 ml of dioxane, argon for 30 minutes, then heated up to 120 ° C, stirred and reacted for 36 hours under the protection of argon to obtain a transparent viscous liquid, named H2O-COOH.

[0033] 3) Add 20 grams of 3-dimethylamino-1-propanol, 30 grams of n-bromobutane, and 80 milliliters of acetone to the 250 milliliter three-necked flask after dehydration and deoxygenation treatment, stir well, and pass argon for 30 Minutes, then heated to 40°C, stirred and reacted for 36 hours under argon protection, a large amount of white precipitate was obtained, vacuum filtered, washed several times with acetone, vacuum dried overnight a...

Embodiment 2

[0037] 1) cleaning the surface photolithography and evaporating the ceramic substrate with interdigitated gold electrodes, and drying for later use;

[0038] 2) In the 100 ml three-necked flask after dehydration and deoxygenation treatment, add 12 grams of hyperbranched compound H O with structure (I), 12 grams of succinic anhydride, 0.24 grams of SnCl 2 , 30 ml of dioxane, argon for 30 minutes, then heated up to 120 ° C, stirred and reacted for 36 hours under the protection of argon to obtain a transparent viscous liquid, named H2O-COOH.

[0039] 3) Add 26 grams of 3-dimethylamino-1-propanol, 34 grams of n-bromobutane, and 80 milliliters of acetone in the 250 milliliter three-neck flask after dehydration and deoxygenation treatment, stir well, and pass argon gas for 30 Minutes, then heated to 40°C, stirred and reacted for 36 hours under argon protection, a large amount of white precipitate was obtained, vacuum filtered, washed several times with acetone, vacuum dried overnigh...

Embodiment 3

[0043] 1) cleaning the surface photolithography and evaporating the ceramic substrate with interdigitated gold electrodes, and drying for later use;

[0044] 2) In the 100 ml three-necked flask after dehydration and deoxygenation treatment, add 20 grams of hyperbranched compound H O with structure (I), 20 grams of succinic anhydride, 0.4 grams of SnCl 2 , 60 ml of dioxane, argon for 30 minutes, then heated up to 120 ° C, stirred and reacted for 48 hours under the protection of argon to obtain a transparent viscous liquid, named H2O-COOH.

[0045] 3) Add 30 grams of 3-dimethylamino-1-propanol, 40 grams of n-bromobutane, and 100 milliliters of acetone to the 250 milliliter three-neck flask after dehydration and deoxygenation treatment, stir well, and pass argon for 30 Minutes, then raised the temperature to 60°C, stirred and reacted for 36 hours under the protection of argon, and obtained a large amount of white precipitate, which was vacuum filtered, washed several times with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| interdigital gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com