Method for cleaning abnormal residual on wafer rear surface after Cu CMP procedure

A back surface, wafer technology, applied in the field of cleaning, can solve problems such as corroded metal, wafer damage, corrosion, etc., to achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

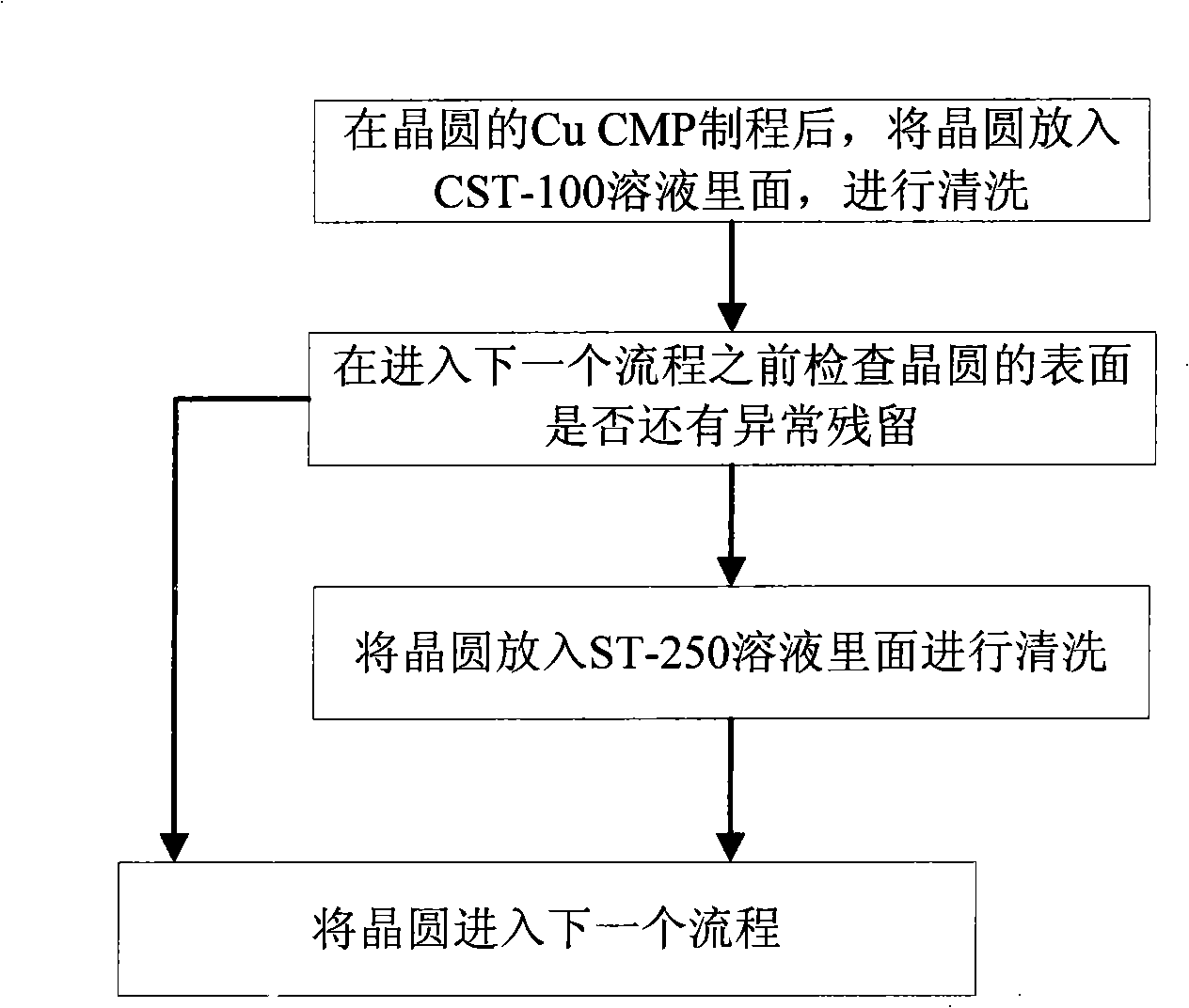

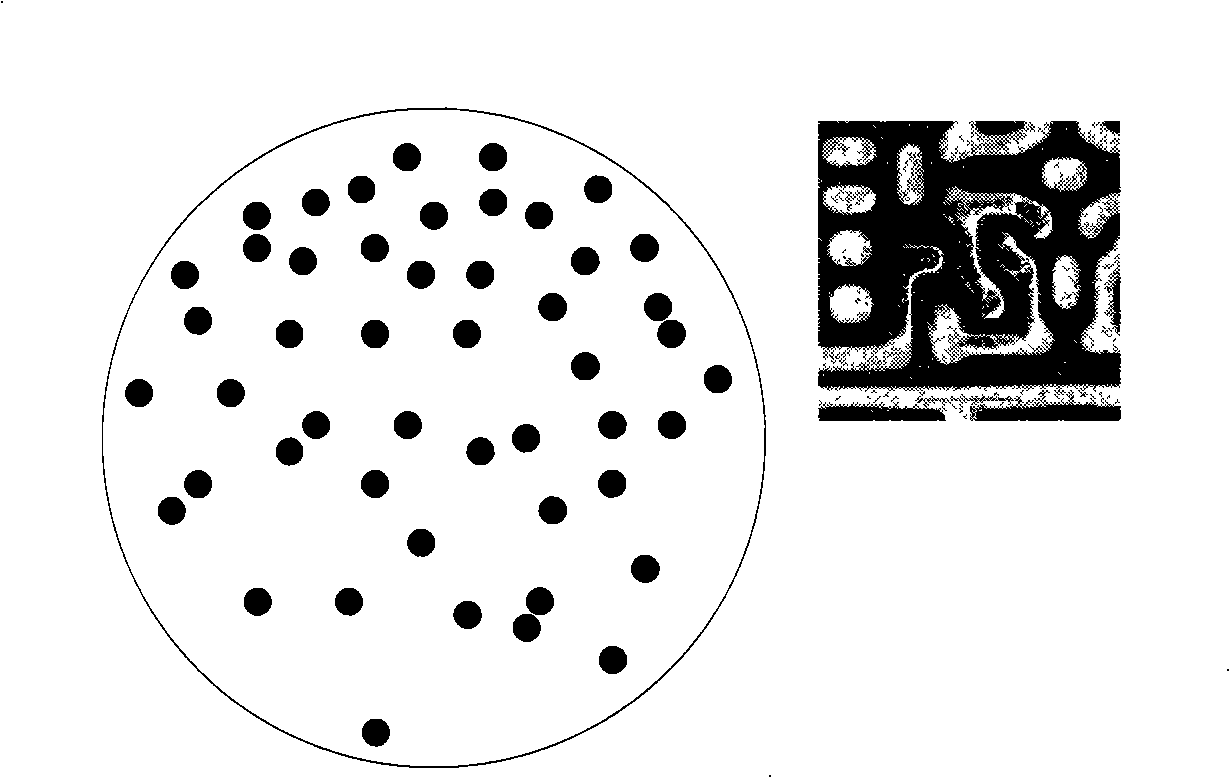

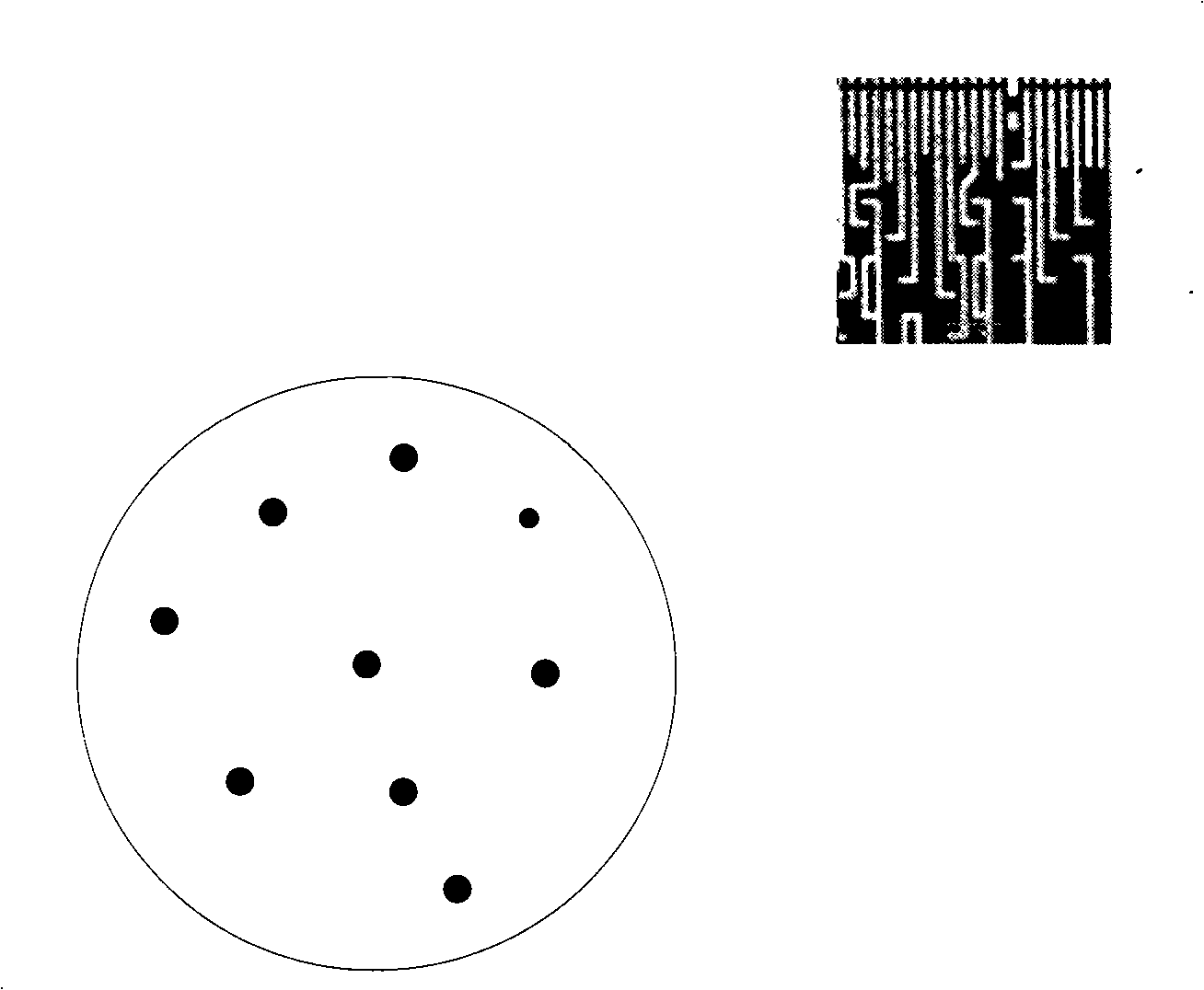

[0017] The present invention is a further improvement to the existing cleaning method, that is, after the Cu CMP process of the wafer, first use the CTS-100 solution to clean the wafer, and check the wafer before entering the next process, if If the wafer is not oxidized and has no impurities on the surface, it will directly enter the next process. If there are abnormal residual impurities on the surface of the wafer, the wafer needs to be further processed, that is, to be cleaned again before entering the next process. And the present invention just makes great improvement to the cleaning liquid in this process, and what this cleaning liquid uses is a kind of new alkaline cleaning liquid, and its pH value is in the scope of 7~9 about, like this again to crystal When cleaning the circle, because the cleaning solution is weakly alkaline, it is difficult for the cleaning solution to react with metal oxides, let alone corrode the metal, and it is easy to clean away other impuritie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com